Si votre demande n'est pas traitée dans les plus brefs délais, veuillez indiquer votre adresse WhatsApp/Skype dans le message, afin que nous puissions vous contacter dès la première fois.

Nous vous répondrons dans les 24 heures. En cas d'urgence, veuillez ajouter WhatsApp/WeChat : ,. Ou appelez-nous directement.

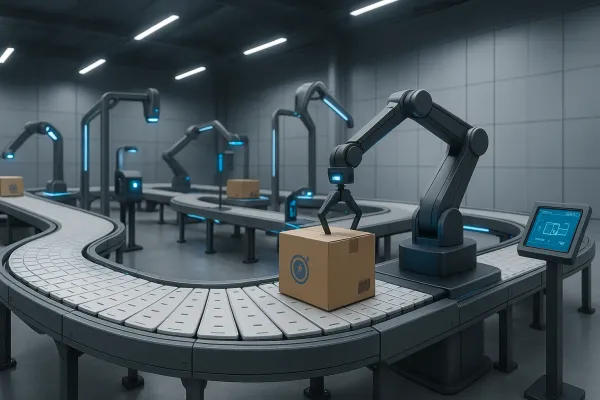

Manual handling slows your line, strains people, and causes errors. Delays pile up. The fix? A smart système de convoyage that moves work fast, safe, and smooth—every hour of every shift.

Un automatic conveyor system is a coordinated l'automatisation setup that moves goods across your plant using belts, rollers, chains, or overhead tracks. It reduces manual handling, raises débit, and improves safety while integrating with packaging machines, scanners, and control systems for real-time flow. It’s the backbone of reliable, scalable operations.

We are a professional manufacturer of automatic packaging machines. That means we design, build, and integrate transporteur lines with checkweighers, case erectors, sealers, wrappers, labelers, and vision QA—so B2B buyers in manufacturing, logistics, warehousing, e-commerce, and distribution get a turnkey line that is fast, compliant, and easy to maintain.

A conveyor is a mechanical device that moves goods between points. In plain terms, it’s a moving path for boxes, totes, parts, or heavy items. Conveyor systems are widely used across factories, DCs, and hubs because they are quick and efficient at moving product without breaks or fatigue. (

A système de convoyage is used when the volume or distance makes carts and forklifts too slow or unsafe. In a system, multiple lines connect workstations so the movement of objects is smooth—receiving to packing, packing to shipping. Conveyor systems reduce travel time and the reliance on manual lifting, while keeping takt time consistent and visible.

“A système de convoyage is a fast and efficient mechanical handling apparatus… minimizing human error and reducing risks.”

De manual systems to fully automated lines, we configure the level of l'automatisation you need today—and leave room for tomorrow.

What is a conveyor

There are many types of conveyor systems. Below is a quick guide to help you match application to type of conveyor:

| Convoyeur | Meilleur pour | Notes |

| Belt conveyor | Cartons, bags, poly mailers | Continuous surface; gentle on product; slope capable. |

| Roller conveyor | Totes, cases with firm bottoms | Gravity or powered; easy merges/diverts. |

| Convoyeur à chaîne | Pallets, racks, fixtures | High load capacity; floor or overhead. |

| Convoyeur à lattes | Hot/dirty or odd-shaped parts | Rigid slats carry non-uniform loads. |

| Convoyeurs aériens | Paint/assembly; free aisle space | Floor clearance; good for long paths. |

These families cover a variety of conveyor needs in a range of industries—from e-commerce to assembly and cold chain. A range of conveyor accessories (stops, pop-ups, pushes, sensors) tune flow and spacing. Common conveyor modules include straights, curves, inclines, declines, merges, and diverts.

We help you choose the right conveyor by testing samples, checking clearances, and confirming stability. The ideal conveyor system supports your rate, product mix, and space constraints without over-engineering.

A ceinture moves items on a flat surface; rollers move items over rotating cylinders; chains pull fixtures or hangers. A bande transporteuse is best when product bottoms are soft or flexible; a rouleau line shines when you want easy accumulation and low friction; chaîne is your go-to for high loads or fixtures.

Belt conveyor modules give a smooth ride for bags and mailers, and the continuous belt helps with angled inclines. Side guides guide and support the belt and keep items traveling along the conveyor belt. For skids or palette loads, a pallet conveyor ou convoyeur à chaîne handles the weight and keeps spacing clean. One convoyeur à lattes option tolerates heat, oil, and chips in machining cells. Convoyeurs aériens clear floor space—perfect when you need a system to transport materials overhead ou un track-mounted system to transport materials in paint and assembly.

Un système de convoyage automatisé links scanners, weighers, printers, diverters, and packers so all stations “see” the same order. That clarity boosts débit et la productivité during peaks. Automated systems also enforce sequence and direction, which keeps WIP from backing up and avoids blockers at packout.

Notre automation system adds smart control systems for sensors, photo-eyes, and drives. With precise control and automation, you can maintain spacing, merge lanes, sort by rule, and hit carrier cutoffs. Warehouse automation becomes practical when your data systems use the same item IDs as your pack lines. One client’s line saw 200% efficiency gains after upgrading conveyors and logic—less rework, fewer jams.

Bon conveyor system designs start with rates, product dimensions, fragility, and future SKUs. The Le système est conçu around the worst-case box and the fastest hour. We map merges/diverts, decide where accumulation is needed, and size drives and supports. Then, we simulate flow to verify débit and buffer.

Notre system integrates with conveyor systems already in your building—stretch-wrap, print-and-apply, or robotic cells. We align PLC tags, safety zones, and HMIs so operators can see jams and recover fast. For paint lines or finishing, we can add overhead conveyors; for assembly, low-back-pressure rollers; for packout, print/apply and weight checks.

Nouvelles tendances dans la conception des convoyeurs

Implementing a conveyor system follows five steps:

We cover loading and unloading ergonomics, guarding, and lockout. We select from a range of conveyor components, then stage FAT/SAT to cut risk. In tight plants, we use compact curves and spirals. For ceiling congestion, we route an overhead system to transport materials overhead; in oily floors, we use sealed drives.

Tip: Start with one value stream, then expand. That’s scalable automation solutions.

Here’s a simple, conservative ROI model (per line):

ASCII chart – illustrative throughput

Units/hour

Before | █████████████████████████ (450)

After | █████████████████████████████████████████ (900)

Key levers

Independent references echo these gains: conveyors limit risky lifts and awkward postures and can cut injury-related costs; industry case studies report big débit jumps when lines are redesigned with accumulation and proper merges.

Manual conveyor systems rely on people pushing goods; powered lines remove much of the strain. Thoughtful stations, waist-high work, and good reach distances reduce manual handling risks. OSHA notes ergonomic changes “reduced physical demands… lowered injury rates” and turnover. That is why conveyor systems reduce risk while improving flow.

In our designs, guarding, e-stops, pull-cords, and control systems are standard. We right-size lifts and declines, add side rails to keep packages stable, and choose surfaces that grip without scuff. As a manufacturer of automatic packaging machines, we make sure the handling system around the conveyor fits the person, not the other way around.

Industrial conveyor systems help e-commerce, 3PL, manufacturing, and transformation des aliments meet speed and compliance. For e-com, conveyor belt systems pair with scanners and scales to label at rate. For factory assembly, convoyeur à chaîne or pallets carry fixtures between stations. For returns, gravity rouleau lines help staging.

In paint and finishing, overhead conveyors keep floors open. For kitting, we use ceinture modules with gentle starts. For inbound palette receiving, chain- or roller-driven transfers handle big loads. We build solutions automatisées that link systèmes de manutention end-to-end—print/apply, weigh, verify, and stage.

convoyeur dans l'usine alimentaire

A bande transporteuse rides on idlers and beds that guide and support the belt. Side guards, sensors, and blockers control gaps. Transfers bridge small spaces so small boxes don’t tip. The Le système est conçu to avoid pinch points and to keep long parts tracking.

We specify drives, brakes, VFDs, and logic based on desired débit and noise targets. For high-rate shipping, we add narrow-belt sorters and shoe diverts; for mixed SKUs, low-pressure accumulation. When we must transport fixtures, we hang them on a chain in a track-mounted system to transport materials with stops and zones for loading.

Start with the SKU: size, weight, packaging, fragility. Confirm your peak hour, then your average. Check how conveyor systems work with your scanners, printers, and pack stations. Make sure your system design considers cleaning, access, and spare parts.

Rappelez-vous : conveyor systems can be customized. If a tote snags, try different rollers or a center drive. If pouches stall, test a slick belt. If cartons skew, add skewed rollers. If you’re moving a new product, you may need a different conveyor surface. The right conveyor is the one that runs your worst-case SKU at rate with zero drama.

A mid-size 3PL installed accumulation zones, right-angle transfers, and pack-to-ship merges. Result: +40% débit, 25% fewer touches, 15% faster carrier cut-off recovery. A similar study from the field shows large increases when conveyors interface cleanly with AS/RS and picking cells.

“Conveyors fall into powered and unpowered groups… belts, chains, gravity, and more.” That mix lets you tailor flow to your products and pace.

Because we are a fabricant professionnel de machines d'emballage automatiques, we pair conveyors with case erectors, sealers, wrappers, and metal detectors. Our system integrates with conveyor systems you already own and the WMS you run. We deliver from manual systems to fully automated pack lines depending on your goals.

We cover everything from conveyor equipment selection to commissioning, training, and spares. Our team ensures implementing a conveyor system is painless—clear scope, tight schedule, and a maintenance plan that fits your crew.

Table – Matching need to module

| Besoin | Module | Pourquoi |

| Slope and soft packaging | Belt conveyor | Continuous surface supports flexible bottoms. |

| Gentle accumulation | MDR convoyeur à rouleaux | Zone control prevents pressure build-up. |

| High loads | Convoyeur à chaîne / transfers | Robust pulling power and alignment. |

| Formes bizarres | Convoyeur à lattes | Rigid slats support non-uniform loads. |

| Free aisles | Convoyeurs aériens | Floor space for people, robots, and lifts. |

Helpful primers and glossaries exist from industry groups and OEMs. They define and compare categories, controls, and interfaces so you can speak the same language in design reviews.

What does a conveyor solution include?

A conveyor solution covers frames, drives, sensors, controls, guarding, and interfaces to upstream/downstream machines. It also covers service, spares, and training so uptime stays high. The ideal conveyor system is sized for your worst-case SKU and your peak hour.

How do I size a line without overpaying?

Start with real rates and the top 20 SKUs. Prototype hard SKUs on test rigs. Pick the simplest path that meets rate. If you later need to automatiser, we can add logic, sensors, and zones as your demand grows.

Les convoyeurs peuvent-ils manipuler des articles fragiles ?

Yes. Use soft-durometer rollers, low-tension belts, or trays. Add accumulation logic to avoid back-pressure. In our projects, these choices reduced les dommages causés au produit while raising rates.

Do I have space for conveyors?

If floor is tight, overhead conveyors free aisles; if ceilings are low, compact curves and spirals help. We also route track-mounted system to transport materials where needed.

Quelle est la maintenance nécessaire ?

Keep belts tracking, clean rollers, inspect guards, and test e-stops. Plan spares for drives and sensors. Our designs make access easy—no special tools for routine checks.

What’s the first step to choosing the right conveyor system?

List SKUs, weights, sizes, and your hourly rate. Walk your flow, note pinch points, and define success. Then we’ll help with choisir le bon convoyeur mix.

(Definitions draw on standard industry resources and primers.

Prêt à automatiser your line? As a factory OEM of packaging machinery and transporteur integrations, we’ll blueprint, build, and commission the right conveyor system for your exact products and growth plan. Tell us your rate, your top 20 SKUs, and your space—we’ll respond with a layout and payback model.

P.S. If you want a fast, low-risk pilot, we’ll stage a short section first—then expand once you’re happy with rate and uptime.