Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Too much packaging slows shipping and eats budget. Overtime rises, waste piles up, and customers wait. A banding machine brings clean automation to your packaging line—fast, safe, and simple.

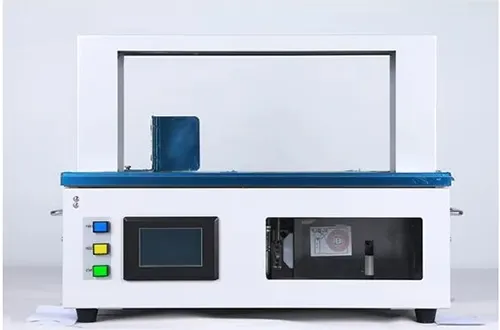

Packaging automation with banding technology uses a banding machine to apply a narrow paper or film band around products or bundles. Compared with tape or full wrap, it speeds the packaging process, cuts packaging waste, lowers labor costs, and delivers a secure, gentle seal that protects surfaces and branding while streamlining shipping.

packaging automation with banding technology

As a professional manufacturer of automatic packaging machines, we build equipment that fits real plants—fast changeovers, stable uptime, and clear ROI for B2B buyers across manufacturing, logistics, warehousing, e-commerce, and distribution. Below is a practical, buyer-focused guide to banding technology and how to make it work in your operation.

Tip: All internal examples below reference product pages so you can see typical specs, applications, and options.

A banding machine applies a narrow band around a product or bundle. The band holds items together without crushing edges or scuffing surfaces. It’s fast, gentle, and clean—ideal for printed items, cosmetics, food trays, cartons, and more. In the packaging industry, banding machines are designed to replace excessive wrap and tape while keeping throughput high.

In packaging automation, you’ll see tabletop units for workcells, floor models for lines, and inline systems tied to conveyors and printers. We often recommend starting with an automatic banding machine for tabletop lines to validate layouts before scaling to larger frames.

Why it matters: a banding machine speeds the packaging process while reducing touches. It’s simpler and kinder to product surfaces than many traditional methods.

Ultrasonic banding creates a seal by vibrating the band’s ends at high frequency. The ultrasonic sealing technology fuses the band in milliseconds without adhesives, heat plates, or fumes. It’s cool, precise, and repeatable—great for delicate goods and printed products.

By contrast, plastic strapping uses a strap under higher tension and a different seal method (heat or friction). Strapping is perfect for pallets and heavy loads; banding shines with smaller, surface-sensitive items. See the difference by browsing paper banding options or materials like PP Strapping Band paired with ergonomic tools.

If you’re considering ultrasonic banding technology, know that ultrasonic banding machines minimize dust, protect finishes, and reduce rejects. The result is a neat, repeatable seal that looks premium and keeps SKUs traceable.

Banding uses banding materials such as paper or film. If sustainability is your goal, recyclable paper bands (often with water-based inks) keep appearance clean and eco-aware. We can print logos and barcodes without smudges. Packaging materials selection is simple: choose paper or film based on moisture, visibility, and branding needs.

From a waste standpoint, bands create less packaging waste than full wraps. That means less material usage and lower disposal fees. Want a starting point? Explore automatic plastic banding machine options that run both paper and film, then iterate. One quick rule: for clear visibility, a paper or film band around trays outperforms shrink wrap on speed and cost.

Sustainability snapshot

You can start semi-automatic: an operator presents the product; the machine bands and seals it. It’s low risk and fast to learn. See a typical semi-automatic option like the YS-A2 semi-automatic strapping machine for reference. For higher throughput, move to automatic banding machines with footswitches, sensors, and guides.

Scaling up, an automatic banding system inside a conveyor cell can handle high-volume packaging without stops. This is where fully automatic or fully automated frames shine. A fully automated system includes infeed guides, detection, tension control, and programmable logic to sync with printers and packaging systems upstream and downstream. See how a line-integrated unit like the fully automatic online strapping machine can tie into your production line.

When to upgrade: If operators fall behind, or quality varies, step to automatic banding machines. If takt time keeps slipping, it’s time for a fully automated cell.

packaging automation with banding technology

Getting tension control right is critical. Too loose and the bundle shifts. Too tight and edges flatten. Choose frames with repeatable, fine tension control and presets for different SKUs—this reduces manual adjustments and speeds changeovers.

Premium frames offer precise tension control to protect soft cartons, jars, and sleeves. For compressible loads, compression plates and guides help you seal cleanly without deformation. Explore compression-capable gear like the automatic arch compression top-pressure machine for delicate packs.

We often pair ultrasonic sealing with low-to-medium tension for cosmetics and confectionery. It locks branding in place while keeping corners crisp.

Three fast wins drive ROI:

We routinely see lower labor costs and fewer reworks once banding is dialed in. Removing manual labor steps and reducing material expenses are common outcomes. Model a conservative case and you’ll likely still justify the capex within a year. For reference layouts, review an automatic carton strapping and sealing machine and compare it with your current flow.

Simple math: If you band instead of full wrap, you often cut material usage while keeping a premium look—this is the definition of efficient packaging. And when you cut touches, labor costs fall too.

Banding shines with printed products (books, catalogs, postcards) because it protects surfaces and barcodes. The seal is neat, labels stay readable, and stacks don’t slip in totes. See a money-handling use case in the automatic currency paper banding machine.

In food packaging, bands secure trays and sleeves without glue residue, and without warm surfaces near food. The same benefits carry into kitting for ecommerce, beauty, and medical devices across a wide range of industries. In short, banding supports various industries and packaging environments where appearance and speed matter.

Why it’s popular: simple training, gentle handling, and clean presentation.

Banding shines with printed products

Start by mapping your packaging process: infeed, orient, band, outfeed, label/print, and inspect. Then decide where to fit banding equipment—typically after kitting or sleeving, before case packing. We often drop frames into existing production lines with minimal lifts or controls work.

For inline performance, consider fully automatic online strapping machines. They tie into packaging systems, accumulate flow during pauses, and keep your production line steady. This is classic packaging automation—and if you feed print data, you also maintain traceability with automated banding.

A useful approach: list your SKUs, throughput, and packaging requirements. Then shortlist banding machine models by arch size, cycle time, tension control, and print options. Next, trial a few banding machines on the market with your real packs.

If you need portable or heavy-duty alternatives, browse industrial banding and strapping pages such as banding machines for sale or box bander machine. This helps you identify the right banding for industrial packaging, compliance, and industry requirements—and to confirm the strap type you’ll standardize on.

Remember: choose banding systems with future growth in mind, not just this quarter’s target.

A fast-moving 3PL needed to bundle products in pairs to reduce picks. Swapping shrink wrap for banding reduced touch time and improved tote density. With a smart tabletop cell, they reached target throughput, then upgraded to a small inline frame.

Frameworks like an auto bander machine for online paper/OPP show how to route parts, seal quickly, and keep labels visible—classic efficient banding that pays back fast.

| Method | Best for | Speed | Surface Safety | Waste | Notes |

| Banding | Small/medium SKUs, sleeves, kits, trays | High | High | Low | Ultrasonic seal; minimal material; print-friendly |

| Strapping | Heavy boxes, pallets, shipping reinforcement | High | Medium | Medium | Higher tension control; choose correct strap width |

| Tape/Wrap | Temporary hold, full coverage | Med | Medium | High | More packaging waste and touches |

For more heavy-duty references, see fully automatic vertical pallet strapping and fully automatic horizontal pallet systems.

Is banding strong enough for daily shipping?

Yes—for small to medium packs. Select the right banding materials and tension control. For very heavy boxes or pallets, pair banding with corner protection or move up to strapping equipment for corrugated lines.

Can I print logos or codes on the band?

Absolutely. Most frames handle inline printing on paper bands, which keeps branding clean on printed products. See compact options like a tabletop paper/film banding page.

Will banding fit my conveyor speed?

Usually, yes. Modern banding machines cycle in under a second. For conveyors, look at low-table automatic strapping and related inline gear to match takt time.

What about food-safe applications?

Banding keeps heat and glue away from food. Non-adhesive bands and cool sealing help. For delicate trays, review side-seal automatic machines and verify materials with your QA team.

How do I migrate from tape or wrap to banding?

Pilot with a workcell, set recipes, and train operators. Then integrate inline. Explore mobile options such as an automatic mobile battery pallet unit if you need flexible stations.

Is banding a fit for sleeves and multipacks?

Yes, especially for e-commerce kits. Check automated banding solutions like an automatic online unit for OPP film and paper to stabilize sleeves without crushing corners.

| Scenario | Best Choice | Why |

| Premium sleeves for cosmetics | Banding | Gentle seal, perfect display, low packaging waste |

| Heavy cartons on pallets | Strapping | High tension control, edge protection |

| Moist environments | Film banding | Resists humidity; still minimal material |

| Limited space workcell | Tabletop bander | Fast changeovers; easy training |

| Multiple SKUs/hour | Inline bander | Recipes, sensors, data logging |

Explore references such as high-table automatic strapping and side-seal carton systems to see layouts that might mirror your plant.

Across manufacturing processes, banding technology is a simple lever with outsized results. Use it to speed cells, reduce labor costs, and keep brands beautiful. Whether you start with a tabletop frame or jump straight to an inline cell, the goal is the same: safe, repeatable automation that protects products and profit.