تجنب تأخير الرد على استفسارك، يُرجى إدخال واتساب/سكايب الخاص بك مع الرسالة، حتى نتمكن من الاتصال بك في المرة الأولى.

سنرد عليك في غضون 24 ساعة. إذا كانت الحالة طارئة، يرجى إضافة واتساب/وي شات: ,. أو اتصل مباشرة.

Tired of wasted film and labor costs from manual stretch wrap? Inefficient pallet wrapping puts your shipments and profits at risk. It’s time to streamline your packaging line with an automatic stretch wrap machine.

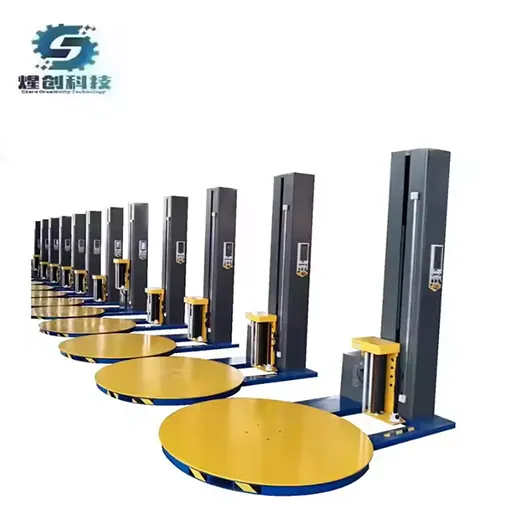

A stretch wrap machine is specialized equipment that uses stretch film to tightly wrap pallets, ensuring secure and efficient packaging for transport or storage. These machines—automatic or semi-automatic—boost productivity, cut costs, and improve load safety for B2B operations.

A stretch wrap machine is an automated solution designed to wrap stretch film securely around pallet loads, making sure your goods stay intact during shipping and storage. The machine applies consistent tension and overlap, providing stronger and more uniform packaging than manual wrap methods.

How does it work?

Explore our automatic pallet stretch wrapping machine for seamless, industrial-scale pallet wrapping.

For manufacturing, logistics, and warehousing operations, time is money—and so is product safety. Relying on manual stretch wrap exposes your business to several risks:

Automated and semi-automatic stretch wrap machines solve these problems:

You can find advanced ماكينة تغليف المنصات النقالة options suited for both automatic and semi-automatic operations.

هناك عدة أنواع من stretch wrap machines tailored for different pallet loads and throughput needs:

| النوع | How It Works | Ideal For |

|---|---|---|

| Turntable Stretch Wrapper | Pallet sits on a motorized turntable that rotates while film carriage moves vertically | Standard or stable loads, medium/high volume |

| Rotary Arm Stretch Wrapper | Arm rotates around stationary pallet, applying film | Heavy, unstable, or fragile loads |

| Orbital (Ring) Wrapper | Stretch film wraps horizontally around long products (using a rotating ring) | Pipes, doors, wood, panel-shaped loads |

The two main categories—automatic و semi-automatic stretch wrap machines—fit different operational needs.

| الميزة | شبه أوتوماتيكي | أوتوماتيكي |

|---|---|---|

| Labor required | Operator for load/unload | الحد الأدنى |

| الإنتاجية | Up to 25–35 loads/hour | 50–80+ loads/hour |

| التكامل | Standalone or basic conveyor | Full integration, inline |

| Price point | أقل | Higher, but better ROI |

| Pre-stretch capability | Yes, usually adjustable | Yes, often programmable |

| Customizable wrap | Manual adjustment | Automated, pattern memory |

For high speed, look into stretch wrap equipment that integrates directly with your conveyorized line.

Selecting the best pallet wrapper أو stretch wrap machine means weighing several technical and operational factors. Here’s what B2B buyers and packaging managers should prioritize:

Want to wrap items beyond pallets? Try our box wrapping machine for cartons and odd-sized boxes.

Stretch film (also known as stretch wrap) is a high-performance plastic film designed for maximum load security and minimal waste. Your choice of film and machine pre-stretch capability can drastically influence packaging costs and pallet stability.

“With pre-stretch, our film usage dropped by 40% and load damage nearly vanished.”

— Packaging Supervisor, Industrial Supplier

For operations with unique or high-volume requirements, stretch wrap equipment can be customized to suit your material and throughput needs.

Automated stretch wrapping equipment is central to any streamlined B2B packaging operation. Integration possibilities include:

Automating your pallet wrapping delivers substantial ROI through labor, material, and damage savings. Here’s what our clients typically achieve:

| متري | Manual Wrap | شبه أوتوماتيكي | أوتوماتيكي |

|---|---|---|---|

| Film Used (kg/pallet) | 1.3 | 1.0 | 0.8 |

| Pallets Wrapped/Hour | 8–10 | 20–30 | 45–80 |

| Load Failure Rate | 7–10% | 2–4% | <1% |

| العمالة المطلوبة | عالية | متوسط | الحد الأدنى |

ROI Example:

A logistics provider upgraded to automatic pallet stretch wrapping machine, saving $30,000 in film and labor costs annually, with a payback period under 18 months.

“We cut film use by half and boosted throughput 3X. Our investment paid for itself in the first year.”

عصري stretch wrap machines are engineered for easy integration:

For specialty needs like luggage or airport bag protection, explore airport baggage wrapping machine و bag wrapping at airport solutions.

Manufacturing & Distribution:

A food processor installed ماكينة تغليف المنصات النقالة models in their warehouse, reducing shift labor by 35% and virtually eliminating pallet collapse during transit.

E-Commerce Fulfillment:

A retailer with high-SKU diversity added a box wrapping machine to automate small parcel bundling, saving space and increasing throughput by 27%.

Heavy Industry:

A coil and tire plant leverages stretch roll wrapping machine for durable, dust-proof packaging of their large products.

How do I choose between a turntable and a rotary arm stretch wrap machine?

Turntable models are best for stable, standard pallets. Rotary arm machines are for heavy, tall, or unstable loads that shouldn’t rotate.

Can I use the same stretch wrap machine for different pallet sizes?

Yes, most pallet wrappers و stretch wrap machines are adjustable for a wide variety of pallet heights and sizes.

What about odd shapes, like pipes or tires?

For non-standard shapes, consider a horizontal stretch wrap machine أو stretch roll wrapping machine.

Can I automate both palletizing and wrapping?

Yes, solutions like stretch wrap equipment و automatic pallet dispenser can be integrated for full automation.

What is manual stretch wrap, and when is it used?

Manual stretch wrap is applied by hand. It’s suitable for low-volume or emergency packing, but not efficient or consistent for regular B2B operations.

Ready to streamline your packaging operations and secure every shipment?

Contact us for expert consultation, a full range of stretch wrap machines, and dedicated support for your B2B packaging automation goals.