Um zu vermeiden, dass Ihre Anfrage verspätet beantwortet wird, geben Sie bitte Ihre WhatsApp-/Skype-Adresse zusammen mit der Nachricht an, damit wir Sie gleich beim ersten Mal kontaktieren können.

Wir werden Ihnen innerhalb von 24 Stunden antworten. Wenn für dringenden Fall, fügen Sie bitte WhatsApp/WeChat: ,. Oder rufen Sie direkt an.

Palletized shipments often shift or tear in transit, causing product damage and unhappy customers. When businesses struggle with inadequate wrap machinery, they face higher costs and safety hazards. Our solution? Discover how the right pallet wrapper and stretch wrap machine stabilize pallet loads and protect your products seamlessly.

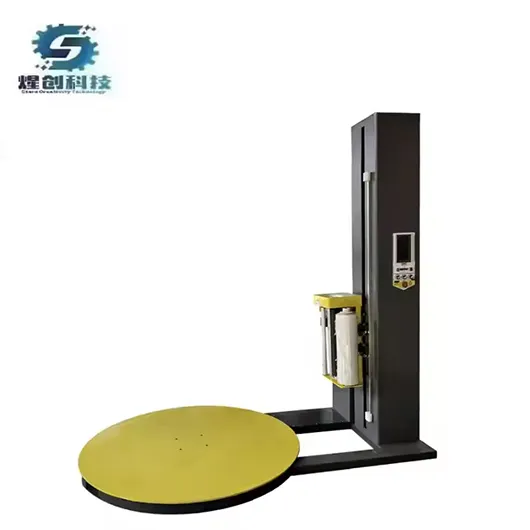

A pallet wrapper is a machine that applies stretch wrap around the load to secure goods for safer shipment. It uses stretch wrap film to tightly bind products on a pallet, preventing shifting or damage during the wrapping process. From small e-commerce setups to large-scale warehousing operations, pallet wrapping equipment ensures better stability, reduces manual labor, and protects goods in transit.

%pallet wrapper and stretch wrap machine

Pallet wrapping is the process of securing products on a pallet with stretch wrap film to ensure that the entire pallet load remains stable during transit. This wrapping process may seem simple, but the careful application of stretch wrap is essential for reducing damage, maintaining consistent quality, and cutting down on potential shipping losses.

As a professional manufacturer of automatic packaging machines, I have seen how palletized loads that are inadequately handheld or poorly wrapped can result in toppling, product damage, and expensive returns. Using effective wrapping solutions—such as a semi-automatic stretch wrap or fully automatic stretch system—makes a world of difference in preserving product integrity, improving warehouse organization, and reducing labor costs. Adopting a dependable pallet wrapper can be especially beneficial for B2B buyers in manufacturing, logistics, warehousing, e-commerce, and distribution.

Wichtige Punkte:

A pallet wrapping machine rotates around the load or rotates the load itself on a turntable, applying layers of stretch wrap film. The wrapper may include adjustments for wrap height, film tension, and number of wraps on the top and bottom. This approach ensures uniform coverage so you can protect your products against moisture, dirt, or accidental tearing.

When the wrapper rotates around the load (or, in some designs, the load rotates), the film is tensioned around the load, creating a secure bond that holds the goods in position. This method is used with both semi-auto and fully automatic pallet wrapping machine solutions.

Besuchen Sie unser Stretchwickelausrüstung to explore advanced models that handle large volumes.

Understanding how to find the right stretch wrapper can be overwhelming, given the variety of wrap machines available. Different operations call for different levels of automation, packaging solutions, and custom features.

Start by considering the weight, shape, and size of your palletized loads. A smaller load may only require a basic semi-automatic stretch wrapper, while heavy loads or tall items might benefit from solutions like a rotary arm wrapper or an orbital stretch wrapping system. Evaluate your daily output: if you wrap pallets per day in high numbers, you may need a high-speed or fully automatic stretch model.

We offer innovative Horizontale Stretchwickelmaschine solutions to help you find the right match for unique dimensions or shapes.

Many businesses wrestle with deciding between a semi-automatic stretch wrap machine and a fully automatic stretch wrapper. Both technologies provide automatic and semi-automatic wrapping solutions but differ in labor involvement, speed, and investment.

A semi-automatic stretch approach typically involves an operator placing the pallet on a turntable, attaching the stretch film, and starting the wrapping cycle. Once done, the operator can cut the film and remove the wrapped pallet. Semi-automatic stretch equipment is cost-efficient, especially for moderate production needs or smaller budgets. This setup is often favored by mid-sized warehouses that wrap pallets per day below a certain threshold.

A fully automatic stretch machine, on the other hand, streamlines the entire pallet wrapping process from film attachment to film cutting. This type of wrapper is frequently integrated into larger packaging systems to handle large volumes in packaging operations. If you have a high-speed environment or you produce palletized loads around the clock, a fully automatic stretch system significantly reduces labor costs and improves consistency.

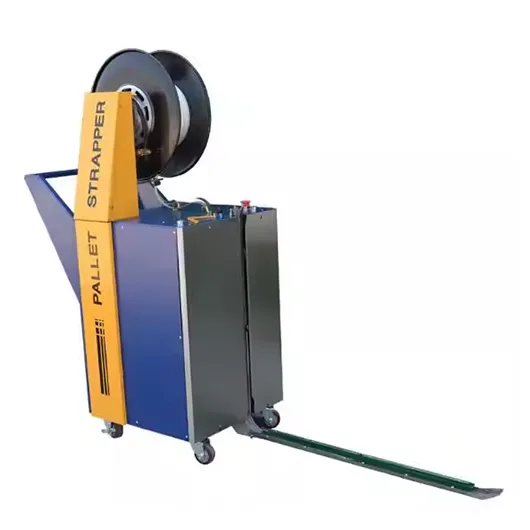

A rotary arm stretch wrapper and a turntable stretch wrapper are two popular options. Each design addresses different needs based on the nature of the load, the available floor space, and your packaging needs.

A rotary arm rotates around the load, making it ideal for heavy loads or unstable pallets. Because the pallet remains stationary, you can wrap delicate or oddly shaped items without risking toppling them. The rotary arm style is often found in fully automatic lines but also as semi-auto units. Additionally, the rotating arm ensures consistent wrapping tension around the load, preventing tear or shift.

With turntable stretch models, the pallet spins on a rotating platform, and the film carriage remains stationary. This design may be more compact, cost-effective, and straightforward to operate. Turntable stretch wrappers are popular for small to medium production floors, especially when forklift access is readily available.

Schnellvergleichstabelle

| Merkmal | Drehbarer Arm | Turntable Stretch |

|---|---|---|

| Load Movement | Stationary | Rotates Around |

| Ideal für | Heavy loads / Delicate loads | Standard Pallets |

| Floor Space Usage | Requires overhead clearance | Smaller footprint |

| Typical Automation Level | Fully automatic or semi-auto | Semi-automatic mainly |

Our Palettenwickler includes rotary and turntable models designed for flexibility and better stability.

Stretch film is the key material used to bind and protect palletized loads. While you might confuse it with shrink wrap, stretch wrap stretches around the load without heat. Once the film is tensioned, it clings to itself, forming a tight seal.

High-quality stretch film not only holds items in place but also ensures durability and clarity. Protecting the load from dust and moisture, stretch film also prevents toppling in transit. Some advanced operations even use pre-stretch film to reduce film usage and cut costs. This approach can significantly reduce plastic waste while offering the same holding force.

Discover our Stretch-Rollenwickelmaschine for advanced stretch film machines perfectly tailored to product shape and weight.

Our journey at my firm, a professional manufacturer of automatic packaging machines, has shown that targeted automation is the biggest catalyst for increased efficiency. The ability to incorporate a pallet wrapper into your packaging systems means less manual labor, reduced risk of injuries, and consistently wrapped pallets.

Use a pallet jacks setup for easy loading onto the turntable or for moving palletized products to a stationary rotary platform. Automated corners and sensors can detect the load’s height, adjusting the wrapping cycle to ensure the entire pallet is covered properly. This style of automation lowers the margin of error and speeds up production.

Consider our Kartonverpackungsmaschine for specialized packaging solutions that can integrate seamlessly into your operation.

Orbital stretch wrapping is a unique technique where the stretch wrap is applied horizontally around the load. The load may pass through a rotating ring or ring-shaped carriage in which the film spool revolves. Orbital wrapping is especially efficient for long or lumber-type items.This automatic pallet stretch approach can simplify the handling of wide or lengthy products.

Fallstudie: We had a customer dealing with banding long aluminum rods for shipping. Shifting to orbital stretch wrapping cut their product damage by 40%, boosted uptime, and lowered labor overhead, resulting in consistent, stable deliveries.

Even the sturdiest wraps can be compromised if forklift handling is careless. To protect your products, ensure that your forklift operators receive proper training on load picking and stacking. Lifting from the correct side or ensuring an even approach reduces the possibility of damage to the wrapped load.

Our Palettenwickelmaschine offers built-in safety features and helps you find the right solution for heavy or fragile loads.

Throughout this guide, we explored how a pallet wrapping process, using a quality pallet wrapper or stretch wrapper, secures product integrity during transit. As a professional manufacturer of automatic packaging machines, I have witnessed how:

• Proper stretch wrap application with the right stretch wrap machine ensures product protection.

• Rotary or turntable approaches cater to different types of loads.

• Semi-automatic stretch vs. fully automatic lines depend on volume, labor, and budget.

• Orbital stretch wrapping and specialized wrap machines are especially handy for unconventional shapes.

• Smooth forklift operations and correct wrapping solutions reduce damage and returns.

• Packaging systems integrated with automation lead to better stability, faster output, and cost savings.

By following these insights, you stand to gain optimized packaging operations, satisfied customers, and a streamlined warehouse workflow that eliminates unnecessary headaches. If you need robust wrapping solutions that provide consistent results, I’d be happy to help you find the right equipment. After all, efficiency, reliability, and innovation are at the heart of what we do here as a trusted supplier and leader in the stretch packaging industry.