Um zu vermeiden, dass Ihre Anfrage verspätet beantwortet wird, geben Sie bitte Ihre WhatsApp-/Skype-Adresse zusammen mit der Nachricht an, damit wir Sie gleich beim ersten Mal kontaktieren können.

Wir werden Ihnen innerhalb von 24 Stunden antworten. Wenn für dringenden Fall, fügen Sie bitte WhatsApp/WeChat: ,. Oder rufen Sie direkt an.

Verlieren Sie jedes Mal Geld, wenn Sie eine Palette verpacken? Die meisten Unternehmen sind sich nicht bewusst, wie viel sie ihre veralteten Verpackungsmethoden kosten. Von verschwendeter Folie und beschädigten Waren bis hin zu den Stunden, die Ihr Team damit verbringt, Paletten von Hand zu verpacken - die versteckten Kosten summieren sich schnell.

Wenn die Paletten beschädigt bei Ihrem Kunden ankommen, wer zahlt dann den Preis? Sie haben - in Rücksendungen, Ersatzlieferungen und beschädigten Beziehungen.

In diesem Leitfaden zeigen wir Ihnen, wie Sie die richtigen Palettenwickelmaschine kann diese Probleme lösen und gleichzeitig Ihre Kosten um bis zu 50% senken. Lassen Sie uns beginnen.

Die Verpackungsprobleme, die Lagerleiter nachts wach halten:

Das sind keine kleinen Probleme. Eine einzige beschädigte Palette kann Tausende von Produkten und den guten Willen der Kunden kosten. Die gute Nachricht? Moderne Stretchwickelausrüstung löst all diese Probleme.

Stars Creativity hat erlebt, dass Hersteller ihren Folienverbrauch um 30-40% senken und gleichzeitig Transportschäden vollständig vermeiden konnten. Ein Lebensmittelhersteller, mit dem wir in Australien zusammengearbeitet haben, sparte jährlich über $45.000 nur durch geringere Folien- und Arbeitskosten.

Nicht alle Stretchwickler sind gleich. Jeder Typ erfüllt einen anderen Bedarf in Ihrer Verpackungslinie.

| Merkmal | Drehteller Wrapper | Rotationsarm Wrapper | Orbital Wrapper | Ring Wrapper | Stretch-Kapuzenpullover |

|---|---|---|---|---|---|

| Am besten für | Gleichmäßige Belastungen | Unregelmäßige Lasten | Lange/weite Artikel | Zerbrechliche Waren | Hohe Luftfeuchtigkeit. |

| Geschwindigkeit (Paletten/Std.) | 20-40 | 30-60 | 15-30 | 10-25 | 15-30 |

| Filmersparnis | Bis zu 30% | Bis zu 50% | Mäßig | Hoch | Sehr hoch |

| Benötigte Fläche | Mittel | Groß | Sehr groß | Groß | Mittel |

| Beste Lastarten | Standard | Schwer/unstabil | Lange Produkte | Gemischte Größen | Lagerung im Freien |

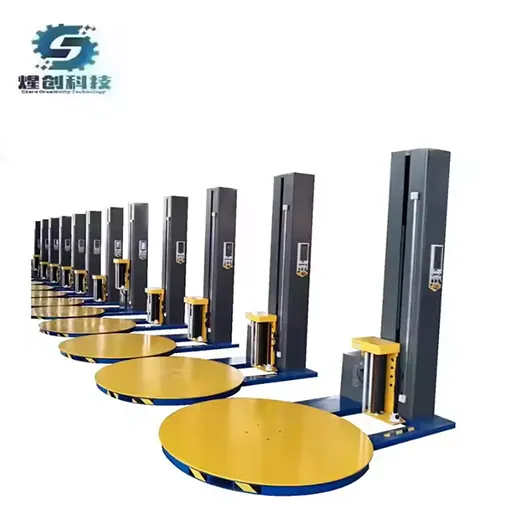

Das Arbeitspferd der Branche, Drehteller-Verpackungen drehen die Last, während sich ein Folienwagen an einem Mast auf und ab bewegt. Diese Maschinen bewältigen die meisten Standardpaletten mit Leichtigkeit.

A halbautomatische Stretchverpackungsmaschine mit einem Drehtischdesign bietet den besten Einstieg für Unternehmen, die von der manuellen Verpackung wegkommen wollen. Die Modelle von Stars Creativity bieten einstellbare Spannung Steuerelemente, mit denen die Bediener das Umhüllungsmuster je nach Lasttyp anpassen können.

Bei schweren oder instabilen Lasten ist eine Dreharmwickler ist die Antwort. Die Ladung bleibt stehen, während sich der Arm um sie dreht und die Folie aufträgt. Dies ist perfekt für:

Für lange Gegenstände wie Holz, Rohre oder Türen ist ein Horizontale Stretchwickelmaschine bietet die perfekte Lösung. Diese Spezialmaschinen wickeln das Produkt nicht vertikal, sondern horizontal um.

Ringverpackungen stehen für erstklassige Automatisierung mit einem Folienring, der sich um die Ladung herum und nach oben/unten bewegt. Sie sind ideal für Hochgeschwindigkeitsvorgänge, die perfekte Konsistenz erfordern.

Wenn maximaler Schutz vor Feuchtigkeit und Staub erforderlich ist, Stretchkapuzen eine vollständige Abdichtung über die Oberseite und die Seiten der Palette herzustellen.

Es ist entscheidend, die perfekte Übereinstimmung zwischen Ihren Bedürfnissen und der richtigen Maschine zu finden. Eine falsche Wahl kann zu Geldverschwendung und anhaltenden Verpackungsproblemen führen.

Der Umstieg von der manuellen Verpackung auf eine Maschine bringt enorme Vorteile mit sich. Aber je mehr Ihre Anforderungen wachsen, desto größer werden die Automatisierungsoptionen:

Das Ingenieurteam von Stars Creativity ist darauf spezialisiert, diese Funktionen genau auf Ihre Produktionsanforderungen abzustimmen. Selbst kleine Anpassungen an den Wickelmuster kann mit der Zeit zu großen Einsparungen führen.

Der Markt für Palettenwickler bietet Optionen in jeder Preislage. Wenn Sie das Verhältnis zwischen Kosten und Nutzen verstehen, können Sie die beste Wahl treffen.

| Marke | Preisspanne | Am besten für | Schlüsseltechnologie |

|---|---|---|---|

| Lantech | $8k-$50k+ | Großvolumige Einrichtungen | E-Serie PLC |

| Robopac | $10k-$45k | Gemischte Ladungsgrößen | Touch-Oberfläche |

| Wulftec | $7k-$40k | Haushaltsautomatisierung | Zuverlässigkeit der WR-Serie |

| Sterne Kreativität | $6k-$35k | Anpassbare Lösungen | Modularer Aufbau & CE-zertifiziert |

Für die meisten Unternehmen amortisiert sich die Investition in weniger als 18 Monaten durch:

Ein mittelständischer Lebensmittelhersteller, der mit Stars Creativity zusammenarbeitete, konnte seine Kosten pro Palette von $0,85 auf nur $0,42. Bei 200 Paletten, die täglich versandt werden, bedeutet das eine jährliche Einsparung von über $18.000 allein für Folien.

Wie moderne Stretchwickler die Effizienz der Logistik verbessern

Typische Einsparungen im ersten Jahr der Umsetzung

Platzbedarf: Gering bis mittel

Ermäßigung pro Palette

Verringerung der Transportschäden

Verringerung des Arbeitsbedarfs

| Metrisch | Vor der Automatisierung | Nach der Installation des Palettenwicklers | Verbesserung |

|---|---|---|---|

| Verpackte Paletten pro Stunde | 8-12 (manuell) | 20-40 (Halbautomatik) | 200-300% Erhöhung |

| Folienkosten pro Palette | $0.85 | $0.40 | 53% Einsparungen |

| Erforderliche Arbeit | 2-3 Arbeiter | 1 Arbeiter | 66% Ermäßigung |

| Schadenshäufigkeit | 4% der Sendungen | Weniger als 0,5% | 87.5% Ermäßigung |

| Konsistente Spannung | Nein | Ja | Verbesserte Laststabilität |

Eine Norm Drehteller-Verpackung benötigt etwa 8' x 8' Bodenfläche, plus Freiraum um das Gerät herum. Dreharmwickler brauchen mehr Platz, in der Regel mindestens 10' x 10'. Stars Creativity bietet kompakte Modelle für Einrichtungen mit begrenztem Platzangebot.

Ja, die meisten modernen Maschinen haben eine Filmwagen mit Sensoren, die die Spannung anhand der Belastungskonturen anpassen. Für extrem unregelmäßige Lasten kann ein Rotationsstretchwickler wird empfohlen, da sie eine gleichmäßigere Folienspannung um Ecken und Vorsprünge herum gewährleistet.

Täglich:

Monatlich:

Vierteljährlich:

Stars Creativity liefert zu allen Geräten umfassende Wartungsanleitungen und Video-Tutorials sowie bei Bedarf auch Fernsupport.

Maschinengeeignete Folien funktionieren am besten mit Leistungsvorstreckung Systeme. Diese Filme sind:

Die beste Wahl hängt von Ihren Produkten und den klimatischen Bedingungen ab. Die Ingenieure von Stars Creativity können Ihnen die optimalen Folienspezifikationen auf der Grundlage Ihrer spezifischen Anforderungen empfehlen.

Für die Grundausstattung wird ein Palettenwickler kann einfach am Ende Ihres Produktionsbereichs platziert werden. Für vollautomatische Lösungen wird der Wrapper mit Fördersystemen verbunden, die oft auch einschließen:

Stars Creativity ist auf diese Integrationen spezialisiert und verfügt über mehr als 15 Jahre Erfahrung in der Verbindung von Verpackungslösungen mit bestehenden Produktionslinien in über 80 Ländern.

Vorher: 150 Paletten pro Tag wurden von 3 Vollzeitmitarbeitern manuell verpackt. Die Folienkosten waren hoch, und die inkonsistente Verpackung führte zu einer Verschiebung der Ladung während des Transports.

Lösung: Installierte eine Mittelklasse Palettenwickelmaschine mit Leistungsvorstreckung Fähigkeit und programmierbare Umschlagmuster.

Ergebnisse:

Vorher: 4%-Schadensquote bei temperaturempfindlichen Sendungen. Risiken für die Einhaltung der FDA-Vorschriften aufgrund eines uneinheitlichen Schutzes. Manuelles Verpacken konnte nicht die erforderliche Spannungskontrolle bieten.

Lösung: Automatischer High-End-Wickler mit Spaltkraftmessung und fortgeschrittene Umschlingungszyklen speziell für den Kühlkettenversand entwickelt.

Ergebnisse:

Der Markt für Verpackungsautomatisierung wächst weiterhin schnell:

Intelligente Fabriken ersetzen zunehmend die manuellen Verpackungsprozesse mit integrierten Systemen. Stars Creativity ist diesen Trends immer einen Schritt voraus, mit kontinuierlichen Innovationen bei Steuerungssystemen, die mit Ihren allgemeinen Lagerverwaltungssystemen verbunden sind.

Der Unterschied zwischen dem Kämpfen mit Verpackungsproblemen und einem rationalisierten, effizienten Betrieb liegt oft in der Wahl des richtigen Partners für die Ausrüstung.

Mit über 3.000 Quadratmetern Produktionsfläche und Exporten in mehr als 80 Länder weltweit verfügt Stars Creativity über die Erfahrung und Kapazität, um Ihre Anforderungen zu erfüllen. Unsere CE-zertifizierten, modularen Designs passen sich perfekt an Ihre individuellen Anforderungen an.

Machen Sie noch heute den nächsten Schritt:

Lassen Sie nicht zu, dass veraltete Verpackungsmethoden weiterhin Ihre Ressourcen aufzehren. Die richtige Stretchwickelausrüstung macht sich schneller bezahlt, als Sie vielleicht denken.

Wenden Sie sich noch heute an unser Team und erfahren Sie, wie wir Ihren Verpackungsprozess in einen Wettbewerbsvorteil verwandeln können.

Stars Creativity - Seit 2005 machen wir Verpackungen intelligenter, schneller und kostengünstiger. Mit unserem Fachwissen in den Bereichen Forschung und Entwicklung, Produktion und kundenspezifische Anpassung von automatischen Verpackungsanlagen beliefern wir die Lebensmittel-, Getränke-, Kosmetik-, E-Commerce-, Elektronik- und Logistikbranche weltweit.