Um zu vermeiden, dass Ihre Anfrage verspätet beantwortet wird, geben Sie bitte Ihre WhatsApp-/Skype-Adresse zusammen mit der Nachricht an, damit wir Sie gleich beim ersten Mal kontaktieren können.

Wir werden Ihnen innerhalb von 24 Stunden antworten. Wenn für dringenden Fall, fügen Sie bitte WhatsApp/WeChat: ,. Oder rufen Sie direkt an.

Factories are busy places. Lots of things need to move. If they do not move well, work is slow. Slow work costs money. This is a big problem for many factories. They lose time and can’t make as many things as they want.

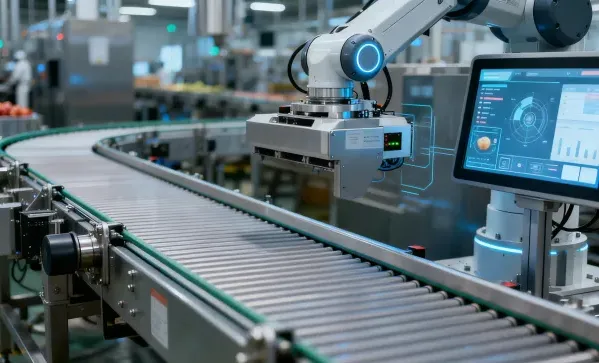

This slow movement is a pain. It makes workers tired. It can cause mistakes. Products can get lost or broken. When the production line equipment is not smart, the whole factory suffers. It feels like you are stuck and can’t grow. This is where a conveyor line changes everything. It is the key to making your factory faster, safer, and better.

A conveyor line is a smart path. It moves things for you. From tiny parts to big boxes, it keeps things moving. This guide will show you how a modern Förderanlage can solve your factory’s biggest problems. We will look at the science behind how they work and why they are so important.

Many places need things to move fast. A conveyor line is the answer. It is a vital part of material handling systems. Let’s see how they help in different big industries.

Car factories are huge. They have thousands of parts. Moving these parts by hand is slow and hard. It can stop the whole automated assembly lines.

When one part is late, everyone waits. The line stops. No cars get made. This costs a lot of money every minute. A stopped line is a factory’s worst nightmare. Big companies like BMW had this problem. They had bottlenecks where work piled up.

They used a Rollenbahn system. This system has special Rollenbahnsysteme on many levels. These industrial conveyors move parts just in time. The cars move smoothly from one worker to the next.

Look at the data. A good Förderbandsystem can make a big difference.

| Industrie | Produktivitätszuwachs | Downtime Reduction |

| Automobilindustrie | 35% shorter assembly time | 94% less downtime |

Mit dem richtigen Förderband, an automotive plant saw a 39% efficiency improvement. This is a huge change. They used a Schwerlast-Scharnierbandförderer to move heavy car parts. This makes the manufacturing equipment work for you, not against you.

Food factories must be very clean. Germs are a big danger. Old machines are hard to clean. They can hide bacteria that make people sick.

If a factory is not clean, it can be shut down. People can get very sick. This can ruin a company. The government has rules. You must follow FDA compliance standards. This is very serious. Coca-Cola needed their bottling lines to be perfect and never stop.

Special hygienic conveyors are the answer. These are sanitary designs made from materials like stainless steel. You can see one example in this Rollenbahnsystem. They have smooth surfaces. There are no places for germs to hide. They are easy to wash. This keeps food safe. A food factory with these processing line conveyors can get a Grade A from the FDA. They have fewer rejections and save over $300,000 a year on cleaning costs. They use things like a spiral conveyor to move food up and down without taking up space.

Förderer in der Lebensmittelfabrik

Warehouses are full of boxes. Think about Amazon. They ship millions of things every day. People can’t find and move all those boxes fast enough. This creates chaos in warehouse logistics.

A slow warehouse means late packages. Customers get angry. They might shop somewhere else. Workers get tired running around. They make mistakes. The wrong item gets packed. This costs the company money to fix.

Factory automation is the key. An automatisierte Förderanlage sorts packages. Barcode scanners read the label. The sorting conveyor then sends the box to the right truck. It is very fast. An accumulation conveyor can hold boxes and release them when ready. This system works 24/7 without getting tired. Amazon uses modulare Fördersysteme to handle up to 15,000 parcels per hour. This lowers their labor costs and makes them 97% accurate. Special telescopic conveyors can even reach inside a truck for easy loading/unloading systems.

Mines move tons of rock and dirt. This is heavy, dusty work. Using trucks is slow and uses a lot of fuel. The dust is bad for workers and the environment.

Fuel is expensive. Trucks break down. This stops the whole mine. Dust can make people sick. The government has rules about dust. If you make too much, you can get a big fine. It is a dirty, dangerous, and expensive problem.

A heavy-duty conveyor is like a long, strong river of rock. It can move 3,500 tons per hour. A drag conveyor or a tough Kettenförderer can handle this heavy load. They use special enclosed chain conveyors to keep the dust inside. This makes the air clean. They use energy-saving conveyors with smart motors called Variable Frequency Drives (VFD). This saves them $2.1 million a year in fuel and makes them 28% more energy efficient. A belt conveyor line is the heart of a modern mine.

Not all conveyors are the same. Each one is made for a special job. Let’s look at the main types of this amazing Verpackungsmaschinen.

Rollenförderer

Unter Sterne Kreativität, we have been building these solutions since 2005. With a big 3,000㎡ factory and a team of skilled experts, we make anpassbare Verpackungsmaschinen. Our machines are CE-certified and are used in over 80 countries. We focus on intelligente Automatisierung to make your factory smarter and faster.

Conveyors are getting smarter. New technology is making them better than ever. This is the world of Industry 4.0 solutions.

Old machines break down without warning. A broken Förderband can stop work for hours. Nobody knows when it will happen.

This surprise stop is a disaster. You lose money every second. Workers just stand around. You might miss a big deadline. You feel helpless because you did not see it coming.

Smart conveyors use IoT integrated conveyors. IoT means “Internet of Things.” It means the conveyor is connected to the computer. It has special conveyor tracking sensors, photoelectric sensorsund temperature sensors.

We believe in making packaging smarter. Our goal is to boost your production, reduce your need for labor, and improve your packaging quality. We want to make your full-line packaging automation simple and cost-effective.

The Smart Future of Conveyor Tech

A conveyor is a hard worker. It needs care to stay healthy. Good maintenance protocols will keep it running for a very long time.

Here is a simple checklist for preventive maintenance:

You can use a simple table to track this:

| Task | Frequenz | Last Checked | Anmerkungen |

| Check Belt Tracking | Wöchentlich | 10/26/2023 | All good |

| Lubricate Bearings | Monatlich | 10/01/2023 | Needed more grease |

| Inspect Drive Chain | Quarterly | 09/15/2023 | Looks worn, plan to replace |

Taking care of your conveyor equipments saves you money. It prevents big, expensive breakdowns. A well-maintained motorisierte Palettenrollenbahn can work for many years without problems.

The world of conveyors is always changing. Here is what is coming next.

Your factory is slow. Your workers are tired. You are losing money and can’t keep up with others.

This is a scary place to be. You worry about the future. You see other companies growing, and you feel stuck. The old way of doing things is not working anymore.

Eine moderne conveyor line is the solution. It is the heart of a fast, smart, and strong factory.

We have seen how a conveyor line is more than just a moving belt.

By choosing the right Förderanlage and taking good care of it, you can change your factory forever. You can boost production, reduce costs, and improve quality. Whether you need a single machine or a complete packaging line, Sterne Kreativität is your trusted partner. We are here to help you build the factory of the future, today. Let’s make your packaging smarter, faster, and better together.