Um zu vermeiden, dass Ihre Anfrage verspätet beantwortet wird, geben Sie bitte Ihre WhatsApp-/Skype-Adresse zusammen mit der Nachricht an, damit wir Sie gleich beim ersten Mal kontaktieren können.

Wir werden Ihnen innerhalb von 24 Stunden antworten. Wenn für dringenden Fall, fügen Sie bitte WhatsApp/WeChat: ,. Oder rufen Sie direkt an.

Loose shipments cause chaos. If your products aren’t tightly secured with the right strap, you risk damage, costly returns, and delayed deliveries. Relying on manual strapping can slow down your packaging process and expose your bundles to risk. The solution? Automated strapping machines that bring speed, reliability, and safety to your packaging line.

A strapping machine is a device that automatically applies, tensions, seals, and cuts plastic or steel strapping around a product or pallet, securing goods for safe transport and storage. Used widely in logistics, manufacturing, and distribution, strapping machines reduce labor, improve efficiency, and guarantee consistent load security.

A strapping machine is a mechanical device that wraps a strap—typically made of plastic or steel—around the product or pallet. Here’s how modern strapping machines work:

With integrated sensors, the machine detects when to activate, minimizing operator intervention. Modern automatic machines can process dozens of packages per minute, making them essential for high-volume operations.

| Schritt | Aktion | Nutzen Sie |

|---|---|---|

| Load | Place product on machine or conveyor | Position control |

| Feed | Machine threads strap around the load | Consistent placement |

| Spannung | Machine applies adjustable tension | Secure product |

| Seal | Heat/friction/metal seal fuses strap ends | Tamper-evidence |

| Cut | Machine trims excess strap | Neat, finished bundle |

Fact: Modern strapping machines require little maintenance, and fully automatic strapping machines can triple output versus manual strapping methods.

There are several types of strapping machines to meet different packaging needs:

Industry Insight: Most modern distribution centers rely on strapping machines—especially automatic and semi-automatic models—to maintain consistent packaging speed and quality. For example, our semi-automatic strapping machine solution is a favorite among mid-size warehouses for its balance of cost and efficiency.

Selecting the right strapping machine impacts your packaging costs, efficiency, and customer satisfaction. If your equipment doesn’t match your production line or packaging needs, you may face frequent jams, wasted strapping material, or damaged goods in transit.

Consider these key factors:

Tipp: Consult with a packaging equipment expert to ensure you’re investing in the right strapping solution for your application. A proper match can lower your total packaging cost by up to 30%.

Strapping machines offer a range of benefits for businesses in manufacturing, logistics, e-commerce, and warehousing:

ROI Table: Strapping Machine Investment vs. Manual Labor

| Method | Packs/Hour | Labor Cost/Year | Damaged Goods Loss | Material Waste |

|---|---|---|---|---|

| Manuelle Umreifung | 50 | $20,000 | Hoch | Hoch |

| Halbautomatisch | 180 | $10,000 | Mäßig | Mittel |

| Fully Automatic | 400 | $6,000 | Niedrig | Niedrig |

“After we upgraded to an automatic strapping machine, our packaging process time was cut in half, and customer complaints about damaged shipments dropped by 40%.”—Warehouse Manager, International Logistics Firm

The main difference between automatic and semi-automatic strapping machines is the level of automation and required operator input.

| Merkmal | Automatic Strapping Machines | Halbautomatische Umreifungsmaschinen |

|---|---|---|

| Einbindung der Betreiber | Minimal | Mäßig |

| Durchsatz | Up to 60+ packs/min | 10–25 packs/min |

| Integration | Conveyor-ready | Standalone |

| Kosten | Higher initial investment | Geringere Anfangskosten |

| Best Use | High-volume, automated | Flexible, lower-volume |

If you need to strap a high volume of products on a continuous basis, automatic machines are essential. For flexible, varied loads, semi-automatic machines often make sense. Explore our semi-automatic strapping machine line for maximum flexibility in medium-scale operations.

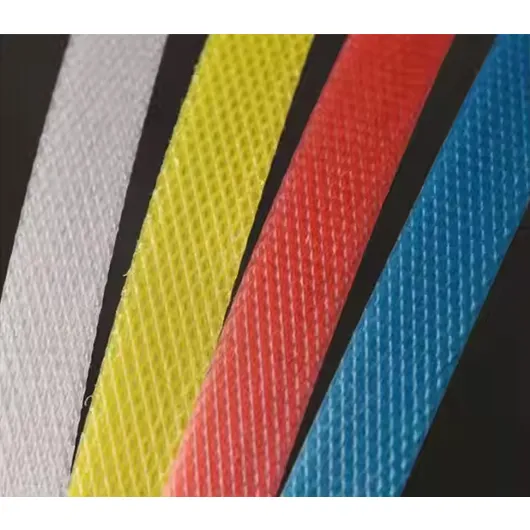

Your strapping material affects the safety and integrity of your packages:

Fact Box:

Tipp: Consider your application—heavy or irregular loads may require steel or high-strength polyester, while cartons and lighter products can often be secured with polypropylene.

To fully automate your packaging process, many facilities integrate strapping machines with conveyor systems and palletizers. This creates a seamless flow:

Benefits of a fully integrated strapping system:

Fallbeispiel:

A major electronics warehouse implemented a Vollautomatische vertikale Palettenumreifungsmaschine integrated with their conveyor. Result: pallet throughput increased by 65% and labor requirements dropped by 35%.

Even the most reliable strapping machine is a mechanical device and needs regular care:

Preventive maintenance reduces the risk of downtime and extends machine life. Always refer to the manufacturer’s manual, and keep a small stock of essential spares for quick repairs.

When a fast-growing e-commerce retailer struggled with shipping delays and damaged goods, they turned to us for a scalable strapping solution. Their old manual strapping process couldn’t keep up: operators could only secure 800 bundles per shift, and inconsistent strap tension led to costly returns.

Solution:

We recommended installing two portable battery strapping tool systems for oversized packages and a fully automatic online strapping machine integrated into their conveyor line for standard orders.

Ergebnisse:

“The new strapping system eliminated our bottlenecks and gave us the confidence to take on larger clients.”—Distribution Center Director

How do I know which strapping machine is right for my application?

Start by assessing your product size, weight, daily shipping volume, and packaging process. For high-throughput lines, a fully automatic pallet strapping machine may be best. For more flexibility, consider a semi-automatic strapping machine for mixed loads.

Can strapping machines handle different strap materials?

Yes. Most strapping machines are designed to use polyester, polypropylene, and sometimes steel straps. Be sure to confirm with your supplier which strapping materials the machine is compatible with.

Is there a big difference between manual strapping and automated systems?

Absolutely. Manual strapping machines are slow, labor-intensive, and prone to inconsistent tension. Automated strapping machines provide faster, more reliable, and tamper-evident results, especially when you need to secure products for long-distance transit.

Do strapping machines require a lot of maintenance?

Routine cleaning and timely replacement of wear parts are typically enough. Modern strapping machines are designed for reliability—just keep an eye on the machine, train your operators, and follow the maintenance guide for trouble-free operation.

Can I integrate a strapping machine into my existing conveyor system?

Yes, most automatic strapping machines are built to work seamlessly with conveyor systems, ensuring smooth flow of pallets and packages through your entire production line.

Selecting the right strapping machine for your business is a decision that pays off in speed, safety, and customer satisfaction. Whether you’re shipping electronics, food products, printed materials, or industrial goods, a well-chosen strapping machine is essential for modern packaging operations.

Learn more about tabletop banding machines and find the right system for your needs.

If you’re ready to take your packaging to the next level, contact us to discuss how a custom strapping machine can streamline your operations and deliver a rapid return on investment.