Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

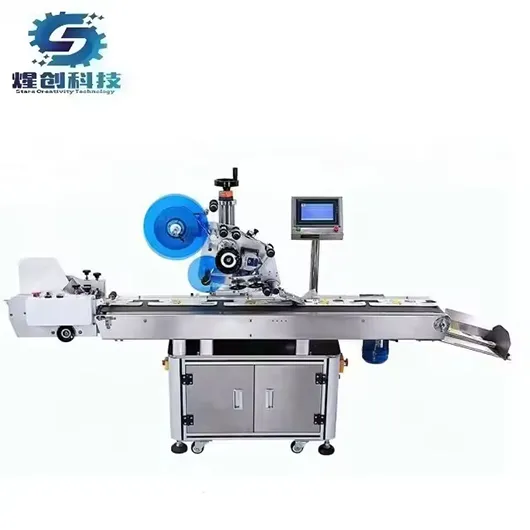

An automatic labeling machine is a device used in packaging lines to automatically apply labels to products. This machine is crucial in industries that require high-speed, accurate labeling of large quantities of products, such as food and beverage, pharmaceuticals, and consumer goods.

Automatic labeling machines are designed to enhance efficiency by applying labels quickly and consistently, reducing the labor required for manual labeling.

Automatic labeling machines have become indispensable in modern packaging due to their ability to improve production speed and reduce the possibility of human error. This article will explain what automatic labeling is, the purpose of labeling machines, and the types of labeling machines available.

Automatic labeling refers to the process in which a machine applies labels to products or packaging without the need for manual labor. This process typically involves automated steps such as label dispensing, alignment, application, and sometimes even inspection.

Automatic labeling systems1 are designed to ensure that labels are applied precisely, quickly, and consistently, significantly improving productivity.

Automatic labeling systems use advanced technology to automate the labeling process, which can involve several steps to ensure efficiency and accuracy:

The labeling machine dispenses the label from a roll. The label is usually unwound by a motorized system, ensuring smooth and consistent dispensing. This step can also involve automatic separation of labels to ensure they are not torn or stuck together.

Once the label is dispensed, it is applied to the product. The machine ensures the label is placed precisely at the correct position on the item or packaging.

In some cases, the labeling machine includes sensors that inspect label placement for accuracy. If a label is misaligned or incorrectly placed, the system can automatically adjust or even reject the faulty product.

Automatic labeling improves speed, consistency, and accuracy compared to manual labeling methods. It reduces the potential for human error and increases throughput, making it ideal for high-volume production environments.

The primary purpose of a labeling machine is to apply labels to products or packaging efficiently. These machines are used across various industries to meet both functional and regulatory requirements for labeling products.

Labeling machines ensure that products are correctly identified, comply with regulatory standards, and improve the overall presentation of the product.

Labeling machines serve several important purposes in a production line:

Proper labeling ensures that each product is clearly identified. This is especially important for consumer goods, pharmaceuticals, and food products, where labels contain crucial information such as ingredients, safety warnings, or brand details.

In many industries, labeling is not just a convenience but a requirement. Labeling machines help businesses meet regulatory standards by ensuring that products are labeled correctly, including batch numbers, expiration dates, and certifications.

Labels also serve a marketing purpose by providing a means of showcasing a brand’s identity. An automatic labeling machine can ensure that each product is uniformly labeled with high-quality labels, creating a professional and consistent look.

Labeling is essential not only for identifying the product but also for ensuring that consumers receive accurate information about the item. Additionally, labels help manufacturers stay compliant with regulatory requirements.

There are several types of labeling machines2, each designed to cater to different needs and types of packaging. The type of machine you choose depends on factors such as the shape of the product, the type of label, and the speed required.

The primary types of labeling machines include wrap-around, front-and-back, top labeling, and print-and-apply machines.

Different types of labeling machines are suited to specific packaging requirements:

These machines are used to apply labels that wrap around the entire circumference of the product. They are commonly used for bottles, cans, and jars. The product is placed on a conveyor belt, and the machine applies the label as the product moves along the line.

These machines are designed to apply labels to the front and back of flat products or containers. They are often used for products like boxes, sachets, or packets where two labels are required on opposite sides.

Top labeling machines are used to apply labels to the top of products. These are commonly used for applications where the product’s top surface needs to be labeled, such as for cartons or trays.

Print-and-apply machines are designed to print labels on the fly and apply them to products. These machines are typically used in environments where each product may require a unique label, such as in shipping and logistics, where tracking information is essential.

Choosing the right type of labeling machine is essential for ensuring that the labeling process is efficient, cost-effective, and compatible with the products being packaged. Each type of machine has its strengths, so selecting the correct one can improve the overall production process.

An automatic labeling machine is a critical piece of equipment for industries that require high-speed, precise labeling of products. Whether it’s for product identification, compliance with regulations, or enhancing branding, these machines provide a fast, efficient, and reliable solution. By understanding the types of labeling machines available and the purposes they serve, manufacturers can make more informed decisions to optimize their packaging lines.