Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Manual work slows orders, creates errors, and stresses teams. Peaks expose bottlenecks. A modern system helps you automate, lift speed, and keep quality steady.

Automated packaging machines are integrated systems that form, fill, seal, label, and get goods ready-to-ship. They combine controls, conveyors, and robotics to cut changeover time, reduce mistakes, and raise throughput for efficient packaging at scale.

A modern packaging system links forming, filling and sealing with inspection, labeling, and data capture. Each station talks to the others so the conveyor and belts move in step. Smart sensors watch for jams and adjust speed to streamline operations. The aim is consistent packs that meet strict packaging requirements without constant supervision.

To automate well, start with a clear map of the entire packaging process, from infeed to palletizer. Specify the right packing machine modules, choose a sealer for closures, and define interfaces to upstream mixers or downstream printers. Keep OEE targets in view to increase efficiency, safety, and uptime while your team stays focused.

What is a modern packaging system

Automated packaging systems tie PLCs to MES and warehouse management platforms. You can integrate scanners for product identification, weigh cells for accuracy, and vision-guided cameras to locate parts. Once cases are complete, a case packer collates units and a robotic arm builds layers before stretch wrap and labeling.

Layouts vary across industries, so connection details matter. Recipes for changeover, HMI checklists, and tooling guides help operators swap SKUs fast. Dashboards visualize throughput and downtime; alerts prompt action for faster delivery and steadier output.

Deciding on fully automated flow depends on SKU mix, volume, and labor. If your end of line packaging sees peaks or heavy lifting, automation improves safety and consistency. Label rules, pallet patterns, and ship tags can print and apply automatically so pallets leave in a ready-to-ship state.

Going all-in isn’t the only path. Hybrid cells are scalable: start with semiautomatic case packing and a compact robotic palletizer. Upgrade to AGVs later as volumes rise. You keep capital disciplined while material handling stays simple.

Matching a packaging machine to your product starts with primary pack style and protection. Flow wrapping presents tight film; vertical form-fill-seal forms a bag for grains and powders; horizontal systems handle a pouch for delicate items. Case erectors create sturdy shippers, while display trays support retail-facing multipacks.

In food and beverage, gentle handling matters. For fragile goods, pick and place heads with soft grippers avoid damage, and sensors confirm seals. Plan your range of packaging so formats stay consistent, protective, and shelf-ready as SKUs grow.

Turnkey scope reduces risk. As a professional manufacturer of automatic packaging machines, we deliver packaging equipment, controls, FAT/SAT, operator training, and lifecycle support. These automated packaging solutions connect order data to printers, validate GS1 codes, and trigger sortation so parcels meet e-commerce carrier rules.

Across the supply chain, packaging automation buffers labor gaps and seasonal surges. Standard modules for cartoning, case packing, and stretch wrapping simplify sourcing and maintenance. The approach streamlines the handoff from line to dock and keeps schedules predictable.

automated packaging solutions for e-commerce

Plants live and die by uptime. Quick-change tooling and coded guides shorten changeover so lines restart in minutes. SMED methods, auto-splice film carriages, and recipe-driven adjustments on the packer maintain flow without drama.

Quality improves with feedback loops. Inline checkweighers, vision seals, and torque monitors catch defects early. Dashboards show trends and waste reduction so teams can optimize schedules and maximize productivity based on real data, not hunches.

“You can’t control what you don’t measure.” Use simple KPIs—OEE, cost per pack, and first-pass yield—and review them daily.

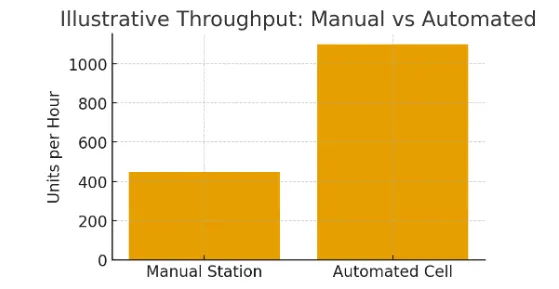

| Metric | Manual Station | Automated Cell |

| Avg units/hour | 450 | 1,100 |

| Operators per shift | 4 | 1 |

| First-pass yield | 97% | 99.6% |

| Changeover minutes | 40 | 12 |

| Chargebacks/month | 6 | 1 |

Chart: Illustrative throughput comparison (manual vs automated).

Illustrative throughput comparison

Vision-guided robotics pick irregular shapes with precision. Cameras find orientation and software supplies coordinates so cups or soft fingers place items into pockets, clamshells, or cases. That accuracy keeps case packing uniform and reduces rework.

For multipacks and cartoning, collators build lanes and servo pushers load shippers accurately. Where speed spikes, a case loader or a compact robotic unit keeps pace. The combination stays stable as SKUs rotate through the year.

Corrugate quality affects reliability. Damp boxes sag and jam, so control storage humidity and rotate stock. At the end of line, print-and-apply labels confirm content and route products on pallets to the correct dock door. One master rule: don’t starve the palletizer; keep cases flowing consistently.

Upstream, packing systems combine accumulation tables with a conveyor spine to balance flow. Downstream, scanners and bump turns stage lanes for loading. When signals sync, the system feels quiet—even at speed—because every handoff is predictable.

Compliance begins with clean design, guards, and lockout points. Traceability depends on time-stamped codes and lot records inside packaging operations. If a recall occurs, search tools retrieve affected SKUs in seconds, and interlocks prevent unsafe starts after a stop.

Auditors look for SOPs, training logs, and calibration history. Digital checklists, maintenance reminders, and spares lists keep teams ready. When specs change, revision controls and signoffs prevent mix-ups that cause rework or fines.

Direct savings come from lowering labor costs and unplanned downtime. Indirect gains include smaller environmental footprint and higher customer ratings. When stations are balanced, plants see increase productivity and steadier shipments even during peak weeks.

The math is simple: fewer touches, shorter lead times, more consistency. Automation packaging cuts defects and streamlines the packaging process. Track cost per pack, OEE, and first-pass yield and adjust weekly. Small tweaks compound into big wins.

You can find the right machine by drafting a tight URS: products, formats, speeds, sanitation, and utilities. Map floor space and guarding. With that, a partner can propose automated solutions, realistic build times, and training plans that fit your budget and timeline.

Design the packaging line for flexibility. Use modular frames, quick disconnects, and spare room for a future infeed. Choose controls that maintainers understand and that integrate cleanly with ERP. Scalable today means survivable tomorrow.

In snack food, films are thin and seals matter. A VFFS cell can form a bag at speed, then a checkweigher verifies fill and a metal detector confirms safety. Shippers receive multipacks, labels print automatically, and pallets stack in stable patterns.

Gummy lines are sensitive to scuffs. A pouch format protects shape, and pickers place bags into cases without crushing. With tuned lanes and belts, output rises while rejects fall—steady proof that design choices drive results.

What products are the best fit for automated packaging?

Any repeatable task with steady flow is a candidate—beverages, personal care, electronics, and component kits. If the work repeats and accuracy matters, automation can match pace, improve quality, and stabilize staffing.

Do I need robots everywhere?

No. Many lines blend mechanical machines with robotics where it adds clear value—heavy lifts, fast picks, or late-stage variety. Start focused and expand as volume and confidence grow.

How long does a typical project take?

Small cells install in days; full lines take weeks. Site prep and utilities set the rhythm. Pilot runs confirm labels, shippers, and pallets meet carrier and customer rules before ramp-up.

How do I keep maintenance simple?

Pick standard parts and local suppliers. Provide tool-free access, clear PM checklists, and short training videos. Remote diagnostics helps teams fix issues quickly without waiting on-site support.

Can automation lower my total cost?

Yes. Lower touches reduce errors, labor costs, and scrap. Better balance means fewer chargebacks and smoother delivery windows, which lowers penalties and keeps customers happy.

We run many SKUs—will changeovers hurt us?

With coded guides, recipes, and quick-release tooling, changeovers can be minutes, not hours. Your team gains confidence through repetition and clear visuals.

If you’d like, I can tailor this to your plant layout, SKUs, and target speeds—so you can move from concept to a locked-in, production-ready design.