Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

When orders spike, strapping can turn into a daily headache: uneven pulls, rushed cuts, and bundles that look “okay” but fail in transit. That stress spreads—rework rises, complaints grow, and shifts blame each other. The fix is to standardize the strap cycle with equipment that repeats the same steps, every time.

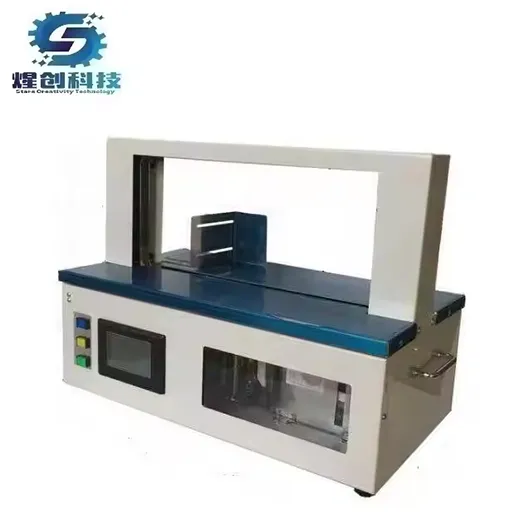

An automatic banding and strapping machine for packaging applies a strap around items with controlled tension and a reliable joint, so you can bundle, secure, and ship goods with fewer variations than manual methods. It’s the best choice when you need consistent results, stable labor planning, and predictable output.

I’m a professional manufacturer of automatic packaging machines, and I’ve spent years watching this step in real factories—manufacturing, warehousing, e-commerce, and distribution. Here’s what I learned the hard way: the best station is not the fastest on paper. It’s the one that produces the same strap result on Monday morning and Friday night, with fewer “special tricks” needed from the team.

To make this useful, I’ll share a buyer-friendly framework, two quick tables, and a simple case study you can adapt to your own numbers.

A strapping machine becomes “automatic” when it controls the full loop—feed, tension, join, cut—using repeatable settings instead of relying on wrist strength and habits. In simple terms, it removes “guesswork” from the wrap and makes the process consistent across shifts, so the station fits cleanly into your packaging line. In day-to-day work, strapping machines allow you to keep results steady even when staffing changes. This is what most buyers mean by automatic strapping.

In practice, you can automate the station with sensors, foot switches, or basic recipes for different products. That matters for certified operations, because you can document settings and repeat them. We’re also seeing more automation across warehousing and distribution, including robotics adoption in packaging and logistics operations.

What should you define before you request quotes?

One more thing that helps: write down two or three KPIs you care about, like rework rate, damage claims, or how often a strap lands in the wrong spot. When we test a station, we don’t just watch speed—we watch consistency. If the same product gets five straps and they look different, the process is not stable yet.

If you bring this list to suppliers, you avoid vague proposals and get a faster, cleaner comparison.

What is an automatic strapping machine

Start with the job the strap must do. If you bundle small printed products, kits, or grouped parts, banding can be perfect—clean look, light tension, fast handling. If you ship heavier items or stack cases, you usually need a stronger strap and higher tension for stability. That choice is the core of a good packaging solution.

When buyers compare banding solutions, I tell them to test two things:

You’ll also see suppliers calling a light bundler a banding machine, so don’t buy by label. Define strap width, tension range, and product surface needs first. If you want faster bundling with a tidy finish, automatic banding can be a great fit. If you need stronger shipping restraint, consider fully automatic banding machines or heavier strapping options, especially when you ship higher weight units.

One more buyer tip: think of strapping and banding as two tools in the same toolbox. Many warehouses use both—one for neat bundles, one for shipping restraint—so you don’t force one method to do everything.

Buyers often ask for the “top” option, but the smartest purchase matches the real workload. There are many types of machines in this category, and they exist because production realities differ—SKU mix, staffing, training, space, and peak season spikes. If you plan for the wrong level, you either overpay or hit a bottleneck.

A semi-automatic station works well when products vary and the team needs flexibility. A fully automatic station is best when the flow is steady and you want minimal touch time. Either way, the point is to save time by removing extra steps and reducing rework.

A quick comparison (use this as a starting checklist):

| Level | What happens | Best fit | Buyer warning |

| manual tools | workers tension and cut by hand | very low volume | high variation |

| semi station | worker places product, machine cycles | mixed products | speed cap in peaks |

| arch-guided station | consistent strap path | stable bundles | needs size discipline |

| line-triggered station | sensors trigger cycles | repeat sizes | needs line balance |

I’ll add one floor reality: some teams call the mid-level options “semi” in daily talk. That’s fine—just map every step so everyone understands who places the product, who triggers, and who clears small jams.

Also, pay attention to production volumes, not just speed claims. If your output swings 2× in peak season, ask suppliers how their strappers handle shift-to-shift changeovers and strap loading.

An arch is a guide frame that creates a consistent strap path around the product. It helps placement stay stable and reduces misfeeds when shifts change. Many suppliers refer to these units as arch strappers because the guide frame is central to repeatability.

If you’re choosing this layout, request a demo of an automatic arch cycle using your actual product. Watch corners, labels, and edges. If product sizes vary widely, a tight guide opening can cause jams or inconsistent placement, so define size rules early.

Maintenance matters too. Choose a layout your team can clean and clear quickly, with simple access to wear parts and strap paths. Uptime is not magic—it’s design plus routine.

A table top strapping machine is ideal when items come to a station and leave by hand—common in kitting, light assembly, and mixed order packing. This approach fits sites with many small-to-medium goods and frequent changeovers.

To choose correctly, define your load sizes and where the strap must sit on a carton. Then look for:

If you do box strapping for many SKUs, ease-of-use often matters more than peak speed. Also plan the motion: place item, trigger cycle, remove, stack. Good layout beats fancy features.

This is where I remind buyers: pick the machine for your application, not the one with the longest spec sheet.

table top strapping machine for mixed carton work

A moving line changes everything. When product flows automatically, you need correct timing and spacing—more than raw speed. That’s where line integration helps: sensors trigger the cycle at the right point, and the station behaves the same on every product that meets the size rules.

For higher volume sites, I often recommend a simple conveyor system with clear stops, safety guarding, and predictable indexing. In a fully automated line, this consistency also reduces downstream fixes. This is a strong path for automated strapping because it reduces touch points and keeps handling consistent. It also supports automatic strapping systems that can communicate with upstream and downstream equipment.

A short case study (example you can adapt):

| Scenario | Before | After | What changed |

| Boxes per shift | 900 | 900 | same volume |

| Rework time per box | 6 sec | 2 sec | better placement + consistency |

| Rework time per shift | 90 min | 30 min | fewer “fixes” |

| Time recovered | — | 60 min | stable schedule |

Rework time visualization (simple and honest):

“If the strap looks the same, my team trusts the load.” — Warehouse supervisor (e-commerce fulfillment)

That’s one hour back per shift. Over 250 shifts, that’s 250 hours. Even before you price labor, you can see why B2B teams choose automation when they run high production and can’t afford late dispatch.

If your site can’t change the line, a solo station can still work. Just measure handling time honestly and set realistic targets. The strap result still needs to be consistent—or you’ll simply move the problem from packing to shipping.

Manual strapping can be useful for low volume, field jobs, and odd loads. But it brings two common issues: high variation and higher safety risk. Loose wraps happen when pulls differ; over-tight wraps happen when someone tries to “make it extra safe.”

If you rely on handheld strapping today, review how you store, cut, and dispose of strap ends. Safety guidance warns that strap cutting can create sharp edges and recoil hazards, so PPE and safe cutting methods matter.

Keep your strapping tools for exceptions and rework, but document your strapping needs and train the team. Small habits—like safe cutting zones and clear disposal bins—reduce injuries and quality surprises.

Manual strapping and handheld strapping tools

Most buyers compare two common materials: polypropylene and polyester. The key difference is how they hold tension over time—especially when loads sit in storage or move through longer distribution chains.

If you’re sourcing for cost, you can still be economical: choose the lowest-cost strap that meets the load need, then confirm it runs cleanly in the machine. Many buyers call this poly strapping, and you may see “pp” used as shorthand.

A quick buyer table:

| Material | Best fit | Common risk if misused |

| polypropylene | light bundles, short transit | tension drop over time |

| polyester | longer storage, tougher handling | over-tension if not set right |

One practical rule: if the load will sit in storage or in a long chain, tension retention becomes your friend. If the load moves fast and stays light, simpler material choices often work.

When you ship in bulk, stability beats looks. That’s why pallet strapping machines matter for distribution and manufacturing. They support horizontal strapping patterns for stacked cases and other heavy-duty shipping units.

A strong setup combines pallet strapping with corner protection and stretch wrapping so you can secure loads without crushing edges. If your team must unitize mixed goods, test different strap locations and tension levels until the unit stays stable through handling and vibration.

If shipping volume is high, ask how automatic pallet strapping handles different stack heights and mixed product surfaces. The goal is consistent tension and repeatable placement, not constant tweaking. This is also where you decide how many straps you need per unit and how you want to stage product for the station.

A spec sheet can’t show real behavior, so I always request a short demo video using the buyer’s actual products. Watch how the station tracks around corners, clears small dust or labels, and recovers from a misfeed. That’s the honest test.

During the demo, check the join quality and tension result, and compare it to your standards. If you run high-speed peaks, ask how fast the station recovers after a small jam and how quickly a new strap coil can be loaded. Official datasheets can also help set expectations; for example, one Signode model lists performance “up to 70” depending on application.

Here’s the checklist I use with clients—these machine features predict long-term satisfaction more than flashy extras:

A reliable strapper should feel boring—in the best way. It runs the same cycle, teaches quickly, and doesn’t depend on one “expert” on the night shift.

If you want to speed up quoting, send suppliers a short “data sheet” instead of a long email thread. I recommend:

This helps us size the frame, choose the right feed path, and recommend spares. It also prevents a common mistake: buying a high-speed unit for a slow station, then blaming the machine. When we quote a strapping machine for B2B buyers, this small worksheet can cut selection time in half.

If you need factory-direct help selecting and integrating certified packaging equipment, my team can help you define the station, test your product, and deliver a stable end-of-line solution—so your shipping team trusts every strap, every day.

How many straps should I use on a carton for safe shipping?

Start with one strap and run a simple handling test: lift, tilt, and stack. If you see movement or bulging, add a second strap or adjust placement. The goal is stability without damage.

What is the difference between automated strapping and manual methods?

Automated strapping uses repeatable settings for tension, joining, and cutting. Manual methods depend on the person’s technique, so results vary more between shifts.

What is pallet strapping used for in distribution centers?

It keeps a full shipping unit tight and stable, reduces load shift, and helps protect goods during forklift handling and transit.

Can I integrate a strapping station with line transport later?

Yes, if you plan space, controls, and safety guarding early. Many sites start with a solo station and upgrade integration after they validate the process.

How do I choose between banding and strapping for small bundles?

Choose banding when you want tidy bundling and low surface pressure. Choose strapping when you need stronger restraint for shipping and stacking.

What should I ask for before I buy?

Ask for a product-based demo, uptime and maintenance details, and a clear spares plan. A supplier who supports setup and training usually delivers better long-term results.