Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Tired of slow, messy bottle label work that eats into profit? Many factories still rely on manual labeling, which causes misaligned labels, rework, and wasted labor. A modern label machine fixes these problems by giving you stable speed, clean bottle labels, and consistent results shift after shift.

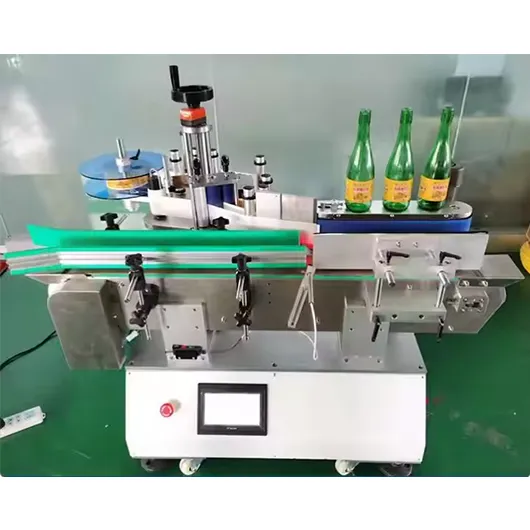

An automatic round bottle labeling machine is a type of label machine that applies a wrap-around label to cylindrical containers like glass bottles, plastic bottles, and metal bottles. It uses a conveyor, label sensor, and a bottle label applicator to place each bottle label at high precision, giving you accurate labeling, higher speed, and less manual work on your production line.

As a professional manufacturer of automatic packaging machines, I talk to many B2B buyers in manufacturing, logistics, warehousing, e-commerce, and distribution. Almost all of them share the same story: they need a reliable round bottle labeling machine that reduces manual work, keeps quality stable, and fits smoothly into their existing packaging equipment and conveyor systems.

In this guide, I’ll walk you through how a label machine for round bottles works, how to choose the right bottle labeling machines for your line, and what to check before investing. I’ll also share practical tips from real factory projects so you can move from interest to a clear labeling solution and finally take action.

A round bottle labeling machine is a special type of label machine designed for cylindrical and cylindrical containers such as water bottles, juice bottles, chemical bottles, vitamin jars, and many other cylindrical products. Instead of a flat surface, the machine has to apply labels around the container with a clean wrap-around label and without bubbles or wrinkles.

In simple terms, this bottle label equipment feeds bottles via conveyor, pulls labels from a roll using a label dispenser, and then a labeler presses the label onto the spinning bottle. A label sensor detects each round bottle label and tells the machine when to start and stop the label application. Because we are a manufacturer of complete packaging machinery, we design the label machine to match upstream and downstream processes like filling, capping, and case packing.

When should you invest in an automatic labeler?

For growing factories, a modern label machine is not just a nice-to-have. It is a basic tool to improve production, keep quality stable, and support future volume growth.

Automatic Round Bottle Labeling Machine

Think of your production line as a road. Bottles travel along this road on a conveyor. The label machine is one “station” on that road, between filling and final bottle packaging. In an in-line automatic setup, bottles move through the automatic labeling system without stopping.

A typical workflow looks like this:

Because we design and build packaging equipment in-house, we can match bottle sizes, material types, and line speeds. Our labeling machine offers adjustable height and angle settings so the same labeler can handle many different labeling tasks across your SKUs.

Many buyers ask whether they should choose a fully automatic or semi-automatic solution. The truth is, both a fully automatic system and a semi-automatic round bottle labeling machine have their place.

Here’s a simple comparison:

| Option | Best For | Typical Users |

| Manual round labeling | Very low volume, testing | Labs, pilot projects |

| Semi-automatic label machine | Small production, many SKUs | Craft brands, niche producers |

| Automatic round bottle labeler | Medium–high volume production | Industrial factories, co-packers |

If you are moving from manual round labeling, even a basic table top label machine can dramatically help by reducing manual errors and making bottle labeling more repeatable. As a manufacturer, we often start clients with a semi-automatic system and then upgrade to a fully automatic inline solution when order volume grows.

When you invest in a bottle labeler machine, you are not just buying hardware. You are buying stability, uptime, and service. That’s why we always ask buyers to look beyond price and focus on machine features that matter for long-term use.

Important features of a modern label machine for round bottles include:

From our factory experience, a high-quality automatic label machine uses cutting-edge technology in controls and sensing to ensure speed and accuracy even for demanding brands. When you choose carefully, your automatic labelers and labeling systems become core assets that run for years with simple maintenance.

As a professional manufacturer, we design each label machine so operators can change settings quickly. This is vital when you handle many SKUs for food and beverage, cosmetics, or chemicals and need a flexible labeling solution.

A common fear from B2B buyers is, “Will this new label machine work with my current conveyor systems and packaging machinery?” The answer is yes—if the equipment is designed with integration in mind.

Our automatic label systems can be installed as stand-alone units with their own conveyor, or they can be mounted beside your existing line. In a typical configuration, the conveyor brings in bottles from the filler, passes them through the round bottle labeling machine, and then moves them to a side labeler, coder, or case packer.

We also consider:

Because our factory builds both labelers and other packaging equipment, we can design a full production line layout from the start. This keeps your return on investment strong and your bottle label quality consistent.

No two factories have the same labeling needs. The right label machine for a small cosmetics brand is not the same as for a high-volume water plant. When we consult with buyers, we always look at a few key points:

We then match you with the correct label machine, bottle labeler, or bottle labeler machine. Adjustments such as rollers, guide rails, and wrap belts ensure accurate labeling for each round bottle format. This is how we help you move from basic interest to strong Desire and finally to the Action of choosing a model.

How to select the right label machine for your round bottle and bottle label needs

For many new brands, the first step into automation is a tabletop label machine. A tabletop round bottle labeler is compact and sits on a bench. Operators place the bottle by hand, and the machine performs the bottle sticker labeling in one smooth motion.

This kind of label machine is suitable for small runs, trade show samples, and pilot launches. It is often widely used in various niche industries where you want professional packaging without committing to a big production line yet. You still get an efficient label and stable quality, but with a smaller footprint and lower investment.

Later, when orders grow, it’s easy to upgrade from a table top solution to an automatic horizontal or in-line system. Because we design both levels, we can keep controls and spare parts similar, making training and maintenance easier.

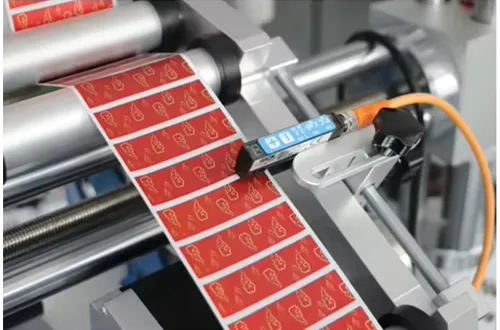

The heart of a round bottle labeler is the wrap around or wrap-around function. A good label machine must keep the bottle steady and apply equal force around the container so that the wrap-around label looks perfect from every angle. This is extra important for premium bottle packaging where your brand image must be clean and sharp.

Key factors that impact wrap-around performance include:

Our machines use cutting-edge technology in drives and controls to keep labels straight even at higher speeds. For many food and beverage plants we serve, this level of consistency is what keeps their brand trusted on crowded shelves.

Let’s look at a simple case from a mid-sized beverage factory. They started with manual and simple manual round tools to apply labels. Operators struggled to keep up, and used for labeling took hours each day. Quality checks found skewed labels, bubbles, and misaligned text.

We installed an automatic round bottle labeling machine as part of a larger automatic labeling system. With the new label machine and conveyor, the line reached higher speed with stable quality. The result:

This is the kind of labeling machine offers we see often: simple changes in packaging labeling can improve production across the line. When you automate smartly, your people can focus on quality and preventive maintenance instead of repetitive bottle label work.

Even though we keep our explanations simple, there are some technical points that matter for engineers and maintenance teams. A modern label machine uses latest technology in motion control and sensing to keep each precise label in exactly the right position.

Some key technical elements:

We often build our machines with industrial PLCs and branded components because they are widely used in various industries and easy to support. For buyers, this means easier spare parts sourcing and shorter down time. Because we are a professional manufacturer of packaging machinery, we design the whole system so your operators can change over quickly, set different height and angle settings, and handle different labeling tasks without fear.

what makes label application so accurate and stable?

For B2B buyers, a good label machine is not only about speed. It is also about compliance, safety, and long-term support. Our round bottle label equipment is widely used in various regulated sectors, where traceability and legibility of the bottle label matter.

We design machines to handle pressure-sensitive labels, support coding devices for batch and date, and meet local safety standards. The body uses stainless steel and anodized aluminum for hygiene and long life. Because we supply complete packaging machinery sets, we can take responsibility for integration and long-term service, not just a single small labeler.

When you partner with a professional manufacturer instead of a trading company, you gain:

This is how we build trust and long-term cooperation with our global clients in manufacturing, logistics, warehousing, e-commerce, and distribution.

Can one label machine handle different bottle sizes?

Yes. Our label machine designs use adjustable guides and rollers to match many bottle sizes. Operators can change settings for different round bottle diameters and heights with simple handles and scales.

What materials can a round bottle labeling machine handle?

Our bottle labeling machines can work with glass bottles, plastic bottles, pet bottles, and metal bottles, as well as other round containers. We test with your actual samples to be sure the grip and automatic pressure are correct.

Can I start with a small machine and upgrade later?

Absolutely. Many customers begin with a tabletop or semi-automatic solution and later move to an in-line automatic system. Because we are a manufacturer of automatic packaging machines, we can design a clear upgrade path and keep your controls similar.

How do I know which label machine is right for my production line?

Share your product photos, label types, daily output, and current production line layout with us. Our engineers will recommend a label machine model, a suitable round bottle labeling machine, and integration with your conveyor systems and other packaging equipment.

Are your label machines widely used in various industries?

Yes. Our labelers are widely used in various sectors: food and beverage, cosmetics, daily chemical, pharma, and more. Because we design the machine label applicator bottle labeler to be flexible, one unit can handle many SKUs across your portfolio.

If you are reading this, you already feel the gap between your current setup and the efficient, stable line you really want. A modern label machine and round bottle labeling machine is a simple but powerful step toward that goal.

As a professional manufacturer of automatic packaging machines, we help B2B buyers:

Whether you need a compact tabletop unit or a high-speed automatic labeler inside a full automatic labeling system, our engineering team is ready to design, build, and support your project.

If you want to:

…then now is the best time to talk to a real factory partner.

Before you reach out, prepare these points so we can help faster:

Bring this information, and we can quickly recommend the right label machine, bottle labeler, or full labeling systems package for your business.