Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Want a fast, reliable way to secure goods without excessive tape or bulky wraps? This guide explains how a band and strap work together with a banding tool or banding machine to lock down cartons, bundles, and even a full pallet. You’ll learn what to choose, how to adjust tension, the best seal options, and how different systems perform in real packaging operations. Read on to save time, reduce packaging waste, and make a better packaging solution decision—confidently.

In packaging, a band (also known as strapping) is a narrow, strong material looped around products to bundle them together or anchor them to a surface. A strap can be tightened with a manual tensioner or by a powered device to apply the right amount of tension. Once tensioned, a seal or joining method keeps the loop closed, creating secure wrapping that resists shifting and impact during handling.

Why choose a band for your packaging needs? Compared with film, a band often uses less material, reduces packaging waste, and can efficiently bundle cartons or tubes with minimal surface coverage. In many operations, banding offers speed, better stack integrity, and a clean look for shelf-ready bundle units. It also adapts to different band material types for varied loads and surfaces.

Helpful resource: see a tabletop solution that handles paper or plastic bands in the automatic 50mm tabletop banding machine for small products and labels: automatic banding machine.

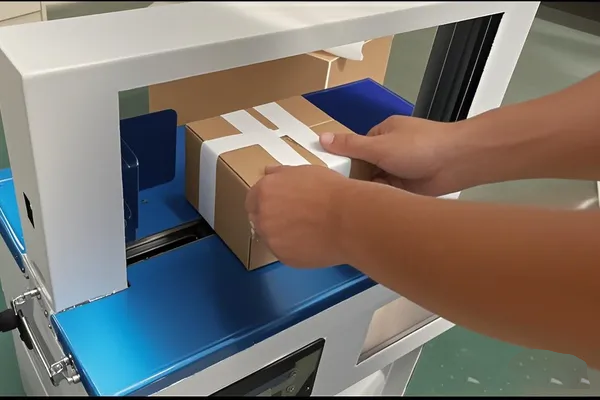

Banding machines work by feeding a band around the item (or through an arch), tightening it to a programmed tension, and then creating a seal—all in seconds. In simple terms, banding machines use either thermal, friction, or mechanical joining to close the loop. Many strapping machines include preset tension settings for repeatability on a busy production line.

As for tools used, you’ll find manual packaging tools like a tensioner tool and sealer, plus semi- and fully automatic machines. A compact bander handles lightweight bundle jobs, while heavy units integrate with conveyor systems to boost throughput. Selecting the right banding equipment depends on your item size, operational requirements, and speed goals.

Helpful resource: to see an entry point for arch-style banding in mixed materials, review the floor unit: box bander machine (floor-type). Another tabletop option for small items is here: automatic online paper/plastic OPP film banding machine.

Manual choices are low-cost and flexible for light to medium jobs; a hand tensioner and sealer close a band quickly for short runs. For higher speed or tougher materials, pneumatic tools use compressed air to pull a stronger tension, ideal for securing heavy loads when you need consistent results shift after shift. Where mobility counts, an electric banding tool eliminates hoses—great for moving around a warehouse.

Consider a battery operated poly option when you need freedom from cords and air lines, especially across large work zones. Balance your application needs (load type, frequency, and operator skill) with total ownership cost and uptime. The right mix keeps your packaging process smooth.

Helpful resource: see portable tools for PET/PP strapping: portable battery strapping tool and a hand air-powered pick: PET/PP pneumatic strapping bundling tool.

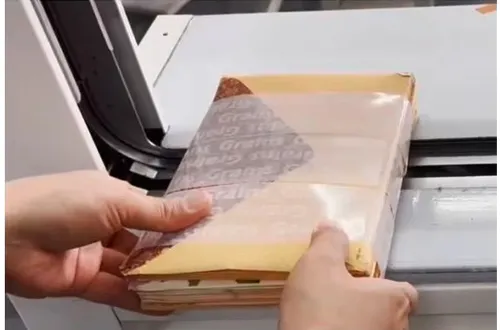

Before you use a banding system, inspect the band edges and confirm your tension and seal method. Load the strap per the tool’s guide, wear protective gear, and keep hands away from the joint. For handheld devices, feed the strap around your item or pallet, leave a short tail, and adjust the tension using the device’s dial or lever. With a manual set, the tensioner tool draws the loop tight while the sealer or buckle closes it.

To use a banding tool effectively, check that the amount of tension matches your goods—too little and the band slips, too much and you risk crushing cartons. On power tools, watch the indicator lights and listen for the cycle that seals the band. If using a metal clip, a metal seal bites the surfaces; otherwise, powered tools make a fused joint. Finally, label the bundle if needed and store the tool correctly so you can prevent unexpected downtime on the next job. Many pros also train staff to use the banding slowly at first, then increase speed as confidence grows.

Helpful resource: for a compact cartoning helper, see this semi-automatic bench unit: YS-A2 semi-automatic strapping machine.

A plastic band is light, clean, and cost-effective for many cartons. Plastic strapping (often PP) works for everyday retail boxes, bundles of lightweight items, and applications where a soft touch matters. When loads are sharp-edged or the climate varies, consider polyester strapping for higher retained tension and better recovery than PP. Here, “poly” choices resist weathering and keep bundle integrity.

For the toughest jobs, steel banding still shines, especially for bricks, metal billets, or lumber. A steel strap handles heat and abrasive edges, though it’s heavier and needs more care in handling. In all cases, match band material to product and surface. Test, note your results, and standardize.

Helpful resource: compare consumables with this page on PP coils and sizes: PP Strapping Band for automatic machines.

There are several ways a machine closes the loop. With clips, a metal seal crimps over the overlapping band. Without clips, friction welds or heat sealing fuse plastic edges. Premium systems add ultrasonic sealing, which vibrates the plastic for a consistent, low-smoke joint. The best choice depends on material, speed targets, and the cosmetic finish you want.

Modern units precisely control tension and join strength. Automatic banding machines can capture cycle metrics so operators repeat winning settings. In many lines, banding machines use an integrated sensor to verify the loop and prevent misfires, while operator prompts guide rework. If you run corrugate and cartons all day, automate where you can.

Helpful resource: explore combined strap-and-seal options here: automatic carton strapping and sealing machine.

Securing a pallet is a different challenge than a small carton. You’re dealing with large loads where lateral shift matters. Choose a stronger strap, add corner protectors, and align bands at structural points. For palletizing, a tall arch with top press helps you apply consistent tension so the stack behaves like a unit. A good system lets you bundle items in tiers and keep skids together for forklift handling.

Safety comes first. Keep body parts clear during loop creation, maintain tool condition, and watch for frayed band edges. When securing heavy stacks, use rated tools and test the joint. Some lines switch to powered arches that handle skids automatically for speed and repeatability.

Helpful resource: see stationary skid systems like a fully automatic vertical pallet strapping machine or horizontal banding for layered loads: fully automatic horizontal pallet strapping machine. For mobile work, check the automatic mobile battery pallet strapping machine.

Think of banding as one node in your packaging operations. On modern packaging lines, a small arch machine after case packers keeps kits together, while in shipping zones, inline arches apply straps as cartons ride a conveyor. To hit higher throughput, plants combine banding and strapping machines with scanners and weighers so one pass identifies, secures, and labels.

To streamline operations, match machine cycles to upstream processes and add error alerts to prevent unexpected downtime. Many sites go from semi-automatic stations to fully automated arches as volume grows, keeping the same consumables for consistency. With vendor technical support, you can spec the right options—press plates, arches, or rollers—to fit your footprint and goals.

Helpful resource: explore online units that sync with lines: MH-102B fully automatic online strapping machine and MH-102A fully automatic online strapping machine. For pressed stacks, see the automatic arch compression top pressure strapping machine.

In print shops, a light band keeps brochures aligned without marking the ink; paper bands are popular where a soft touch matters. In food packaging, a minimal loop can hold pouches together while leaving branding visible and allowing airflow. Many brands even band for labeling, applying artwork on the loop for a tidy shelf look without a sticker.

These jobs often rely on small arches and tabletop units that set gentle tension and make clean joints. If your work mixes paper or plastic media, test the joint to ensure it holds but won’t dent edges. When choosing equipment and band products, check availability, lead times, and vendor service.

Helpful resource: see compact tabletop units for mixed materials:

First, aim for the right banding every time. Standardize your tension settings, verify joints after changeovers, and log settings by SKU. Train teams on tools to secure tricky shapes and on how to set a tensioner so cartons aren’t crushed. Keep spare blades and a backup strapping tool available to prevent unexpected downtime. For brands and sourcing, consider service, parts access, and a reputable brand—market names like strapack are often benchmarks for spec comparison.

Second, keep machines clean and calibrated. Dust and glue buildup can cause misfeeds. Schedule checks aligned to operational requirements, verify sensors, and monitor rollers. If your mix includes PET and PP, record which band goes with which line. When loads increase, consider fully-automatic arches or automated banding cells to expand capacity without expanding staff.

Finally, always think sustainability. Separate spent band tails for recycling where possible and revisit material specs if you can switch to a thinner band without losing performance. That’s how you build a lean packaging process that scales.

Helpful resource: line-ready general-purpose units include:

Do I need steel or plastic for a heavy bundle?

If edges are sharp or hot, choose steel banding or add edge guards. For most cartons, plastic band (PP) is fine; for tougher jobs, PET (polyester) maintains tension better over time.

Can I combine banding with labeling?

Yes—many lines bundle items and apply a band for labeling in the same station, which keeps outer boxes clean.

What if I only have a few pallets per day?

Start with a robust handheld set. As you grow, step up to a semi-automatic arch; later, integrate a fully automated unit for higher throughput.

Explore how band, strap, and the right banding tool combine to secure everything from light cartons to a heavy pallet. Compare tensile strength, sealing technology, and see when to choose manual, pneumatic, or electric banding solutions.