Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Every year, fake drugs kill over 250,000 people worldwide. Manufacturing plants face a growing crisis. Drug tampering happens more often. Leaks destroy expensive medicines. Regulatory fines can shut down entire operations.

Without proper sealing, one contaminated batch can cost millions. The FDA rejected 40% more drug shipments last year due to packaging failures. Manual sealing creates human errors that put patients at risk.

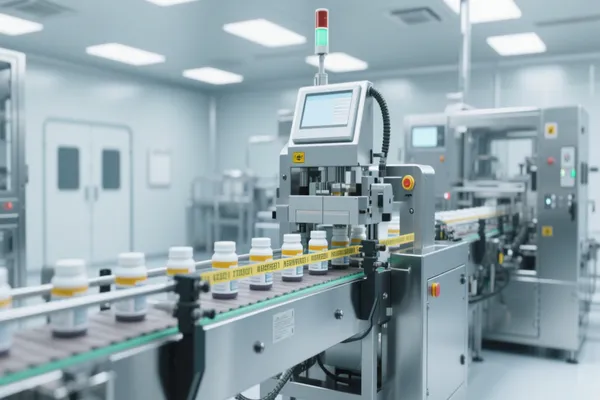

Banding machines provide the answer. These automated systems apply tamper-evident seals to pharmaceutical containers. They protect drugs, meet regulations, and save money.

A banding machine for pharmaceutical packaging applies protective bands or seals to drug containers. These machines work with bottles, vials, tubes, and other containers.

The process works in simple steps:

Heat Shrink Band Applicators use plastic sleeves that shrink when heated. These create visible tamper evidence.

Peristaltic Band Applicators use rotating heated wheels to shrink pre-cut bands onto container necks.

Induction Cap Sealers apply foil liners under caps using electromagnetic fields. This creates an airtight seal.

Drug tampering costs the industry $200 billion yearly. Tamper-evident band applicators show clear signs when someone opens a container. The FDA requires this protection under 21 CFR Part 211.

Liquid medicines lose potency when exposed to air. Hermetic seal banding prevents leaks. This saves expensive formulations from waste.

Fake drugs make up 10% of global medicine sales. Security seal applicators with special printing make counterfeiting harder.

The FDA, EMA, and other agencies require tamper evidence. GMP compliant banding machines meet these strict rules.

Manual sealing is slow and inconsistent. High-speed band applicators process 150-400 containers per minute. This matches modern production needs.

| Feature | Heat Shrink | Induction Sealing | Peristaltic |

|---|---|---|---|

| Speed (CPM) | 200-400 | 300-600 | 150-300 |

| Container Types | Bottles, Jars | Bottles, Vials | All Shapes |

| Band Material | PVC, PETG, OPS | Foil Liners | Shrinkable Bands |

| Tamper Evidence | Excellent | Good | Excellent |

| Changeover Time | 15-30 min | 10-15 min | 20-45 min |

Container Compatibility – Machines must handle your specific vial sizes, bottle shapes, and cap types.

Production Speed – Match your line speed. A continuous motion bander keeps up with high-speed filling lines.

Band Material Options – PVC/PET/OPS band applicators offer different properties for various drugs.

Quality Control – Vision system band inspection catches defects before shipping.

Regulatory Design – Cleanroom banding machines meet pharmaceutical hygiene standards.

Serialization Ready – Track-and-trace band coding supports anti-counterfeiting efforts.

Modern pharmaceutical shrink banding systems connect with other equipment:

Leading manufacturers like Uhlmann, IMA Group, and Marchesini Group offer complete integration services.

Machine qualification follows three phases:

Documentation requirements include batch records, maintenance logs, and calibration certificates.

Artificial intelligence improves defect detection by 30%. Systems from Cognex and Keyence use machine learning to spot problems human eyes miss.

New polyolefin bands reduce environmental impact. These materials recycle easier than traditional PVC films.

Flexible banding systems allow quick changeovers. This helps with smaller batch sizes common in specialty drugs.

Compare heat shrink banding, induction sealing, and peristaltic systems based on your specific needs.

Check vendor experience with pharmaceutical applications. Körber Pharma, Optima Packaging, and Robert Bosch Packaging specialize in pharma equipment.

Plan connections with existing equipment:

Basic bottle banding equipment costs $50,000-150,000. Advanced automated band sealers with vision systems cost $200,000-500,000.

Automated banding typically pays back in 18-24 months through:

Asia-Pacific leads global demand with 40% market share. This growth comes from expanding pharmaceutical manufacturing in China and India.

North America focuses on serialization-ready banders due to Drug Supply Chain Security Act requirements.

Europe emphasizes sustainable packaging, driving demand for eco-friendly band materials.

FDA regulations require checking every sealed container. Band sealing temperature control and seal integrity testing ensure consistent quality.

GAMP 5 compliant systems track all production parameters. This data supports regulatory submissions and quality investigations.

IoT-enabled predictive maintenance reduces unexpected downtime. Sensors monitor key components and predict failures before they happen.

Industry 4.0 concepts bring new capabilities:

New anti-counterfeiting technologies include:

Environmental concerns drive development of:

Train operators on new banding equipment before installation. Partner with suppliers offering comprehensive training programs.

Start with one product line. Learn from initial implementation before expanding to other products.

Monitor OEE (Overall Equipment Effectiveness) metrics. Use data to optimize machine settings and maintenance schedules.

Choose suppliers with:

Companies like Stars Creativity bring 18+ years of packaging automation expertise to pharmaceutical applications. Their banding machines feature CE certification and modular designs suitable for pharma environments.

Install redundant quality inspection capabilities. If one system fails, production continues safely.

Document all machine modifications following pharmaceutical change control procedures. This maintains regulatory compliance.

Qualify multiple band material suppliers. This prevents production disruptions from supply issues.

Banding machines for pharmaceutical packaging solve critical industry problems. They prevent tampering, ensure product integrity, and meet regulatory requirements.

Success depends on choosing the right technology for your specific needs. Consider container types, production speeds, and integration requirements carefully.

Work with experienced suppliers who understand pharmaceutical manufacturing. Proper planning and implementation create systems that protect patients while improving operational efficiency.

The investment in quality pharmaceutical banding equipment pays dividends through reduced risks, lower costs, and regulatory confidence. As drug safety requirements continue growing, these systems become essential for sustainable pharmaceutical manufacturing.

Modern automatic packaging equipment offers the reliability and flexibility needed in today’s pharmaceutical industry. Choose wisely, implement carefully, and maintain consistently for long-term success.