Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Small teams struggle to keep up with orders when boxes are built by hand. Delays stack up, costs rise, and customers wait. Choose the right erector to speed flow, cut waste, and scale without chaos.

The best carton erector for a small packaging line is a compact, user-friendly case erector that fits your space, matches your cases per minute target, supports quick changeover, and pairs with a case sealer. It should erect and seal consistently with minimal manual labor.

A case erector is a machine that takes a flat corrugate blank and folds it into a corrugated case, ready to load. In simple terms, it helps you erect boxes fast and straight. For small teams, this replaces manual case work that slows the packaging process and adds errors.

Modern erectors automatically form square, rigid boxes that improve downstream flow and product safety. They can erect and seal bottoms with tape or hot melt, keeping your end-of-line packaging process smooth. Paired with a case sealer, they deliver clean, consistent packaging results.

As a professional manufacturer of automatic packaging machines, we design equipment sized for startups and growing sites. We look at production needs, floor space, and budget, then suggest the best case erector setup to lift productivity and reduce labor costs.

What is a case erector

You’ll hear many names: case formers, box erectors, and carton formers. They all erect boxes, but formats and materials vary. A case former typically handles RSC corrugated blanks; a carton erector often works with lighter board for retail cartons.

In practice, we compare case formers and box formers by speed, stability, and options. Some machines include case forming equipment with case magazines and a bottom tape drive, while others prioritize flexibility for various box footprints and sizes and styles.

For a tiny packaging line, clarity matters. If you ship in RSCs, a case erector machine is right. If you build small retail sleeves, look to carton forming systems. Either way, the former must be simple, safe, and serviceable.

Start from orders and takt time. Most small sites do 8–18 cases per minute. Pick an erector that meets today’s demand and can grow. Too slow, and work piles up; too fast, and you pay for idle capacity.

Compare real speeds by box size and tape type. A compact case erector may run 12 cases per minute on medium RSCs, a little less on tall, light carton styles. Always verify with your exact blanks.

Table: Typical small-line speed vs. size

| Case size (L×W×H) | Tape | Expected speed |

| 300×200×200 mm | 48 mm | 14 cases per minute |

| 400×300×250 mm | 48 mm | 12 cases per minute |

| 500×350×300 mm | 72 mm | 10 cases per minute |

For reliability, look at frame stiffness, magazine design, and the sealer interface. Most case erectors use vacuum cups, former plates, and clean fold paths. Ask for tool-less clear-outs and sensors that spot jams early.

A reliable case erector has guarded drives, easy tape threading, and safe access.

Pair the erector with a matched case sealer so transfers stay square. A bad hand-off causes skew and weak seal bonds. Also check spares, training, and long-term support—these keep your packaging operations running.

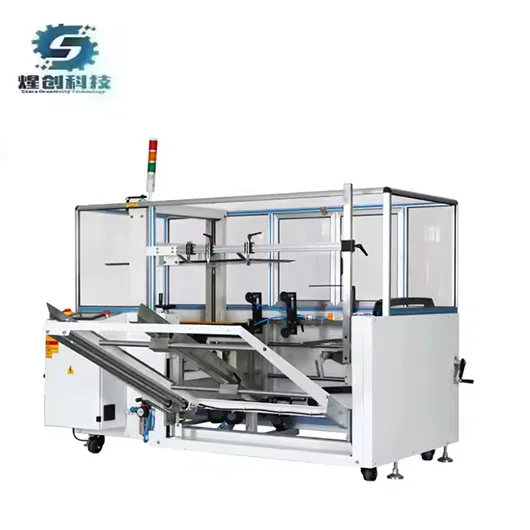

Automatic Carton Erector Machine

Tape is flexible and low-cost; hot melt gives a rigid seal and may run faster. Consider environment, board quality, and budget. Many small lines start with tape and upgrade later.

If you ship moisture-sensitive goods, hot melt can help. If you need easy rework, tape rules. Either way, match tape width and adhesive to your carton specs and confirm pull tests.

Some machines can erect and seal with both methods. Others stick to tape. Review case sealing options before you buy the ideal machine.

Small teams face frequent size swaps. Choose an erector with scales, handwheels, and guides that enable quick changeover. Aim for <5 minutes and minimal tools.

Look for digital counters and pictograms. A user-friendly case setup reduces mistakes. Good designs also support different case sizes without complex parts. This makes changeover calmer in peak hours.

We teach how to erect the right carton every time. That includes tape tension, flap overlap, and squareness. Stable swaps protect uptime and automation gains.

Measure your aisles and existing packaging footprint. Compact erector frames fit tight corners and keep magazines reachable. Verify loading height for operators and pallet jacks.

Safety matters. Ask about interlocks, e-stops, and guards. We design comfortable load heights so staff can erect box blanks without strain. Clear sightlines help new hires work confidently.

Plan hand-offs: erector → packaging → secondary packaging. Smooth conveyors prevent crashes. Good ergonomics lower turnover and boost morale.

Line balance is key. Your production line should flow from forming to load to close. Keep an eye on indexes, backup sensors, and buffers so goods don’t pile up.

We integrate with weighers, printers, and packaging machinery cells. The goal is clean hand-offs at every step of the end-of-line packaging process.

We also build out packaging systems that add scales and checkweighers later. Modular designs protect the future—a smart path for growing lines.

If you run many SKUs or light board, a robotic case erector can shine. With grippers and vision, a robot with multiple case magazines can feed blanks and erect tricky styles.

One layout uses a six-axis robot with multiple case picks to feed a compact former. Another blends robotic case loading and close. Think about uptime, operator skill, and spare parts.

We rarely start small firms here, but we plan for growth. Start with a basic erector, then scale.

When should I consider a robotic case erector

Check the magazine: capacity, low-level alerts, and loading angle. Bigger magazines mean fewer stops and more efficiency in packaging.

Ask about a tape head for random box runs or a head for random box erecting if your sizes jump. Stable tape feed equals a strong seal.

For tough boards or an elvs carton spec, request powered fold rails. Also review case magazines and a bottom drive for square results. These small details separate the best case erector from the rest.

This is where our team of packaging engineers helps. We’ll point to a compact erector that’s fully automatic, safe, and easy to own.

Entry erector units cost less than you think, especially against manual labor and damage claims. Add tape, energy, and PMs to see the whole picture.

Think long-term. A dependable erector lowers jams and touch time, driving consistent packaging quality. A compact unit that can erect square boxes protects goods and keeps packaging needs simple.

We’re a factory erector builder, so pricing is direct. Our company offers a wide range of options and the support to match.

Shoppers often review pearson packaging, combi packaging, and independent builders like us. Each has strengths, from high-speed cells to entry units for startups. Examples include pearson packaging and combi packaging; compare features, service, and price.

Also look at warranty and local service. Big brands and small specialists both deliver great packaging solutions. Pick partners who listen, not just pitch.

We’re candid: some plants fit catalog models; others need custom tweaks. The brand matters less than fit and support.

A cosmetics startup began with manual case erecting and tape guns. Uptime sagged and corners crushed. We installed a small erector beside two benches.

The line moved to 12 per minute with fewer jams. Operators now load blanks and let the machine erect and seal. Quality improved, dents dropped, and returns fell.

Quote from the lead: “We feared big automation, but the compact erector felt natural fast.” That’s the power of steady change.

Yes, usually. Reduced touches, fewer crushed corners, and better packaging flow add up. The right erector improves yield and keeps staff on value work.

Simple math: replace a manual case step with a reliable case erector and protect goods. Even at 10–12 per minute, the payback can be short when shrink and rework drop.

We help you test blanks and belts. If your goods are fragile, we’ll tune case forming pressures and transfers.

How much space do I need for an erector?

Most small units fit in 1.8–2.5 m². Allow room to load and to service the former safely.

Can one erector handle many SKUs?

Yes. With good guides and a changeover routine, one unit can run many sizes without stress.

Do I need a hot-melt option today?

Not always. Start with tape; add hot melt later if your carton or environment needs it.

How do I train my team quickly?

We standardize steps and visuals so new staff can erect boxes the same way on day one.

What maintenance does an erector need?

Keep slides clean, check belts, and replace cups. Plan PM time to guard uptime.

How do I integrate with printers and labelers?

We align heights and controls so your packaging prints stay sharp and square.

Here is a simple, transparent way to see payback. Assume you hand-build 1,800 boxes per shift, two shifts per day. A compact unit runs 12 cpm with one operator, reduces touch time, and cuts dunnage waste.

| Item | Hand-built | With unit |

| Boxes/shift | 1,800 | 2,400 |

| People on box build | 2 | 1 |

| Rework/damage rate | 2.5% | 0.8% |

| Tape per box | 1.6 m | 1.2 m |

| Est. yearly savings | – | $48,000–$72,000 |

Quick math: if the system price is $38,000–$55,000, savings alone can deliver payback in under a year. You also free staff to pick, kit, or QA where they add more value.

“After install, corners stopped crushing. Returns fell 37% and morale went up.” — Ops lead, midwest cosmetics

Savings drivers (illustrative)

Labor ████████████ 52%

Waste ██████ 21%

Rework █████ 17%

Damage ███ 10%

Use this quick matrix to align must-haves with nice-to-haves. Keep it on your RFQ so vendors respond to the same scope.

| Need | Feature | Why it helps |

| Tight space | Small footprint frame | Fits corners and narrow aisles |

| Many sizes | Tool-less guides | Faster swaps and fewer mistakes |

| Light board | Powered fold rails | Keeps square shape on thin stock |

| Print labels inline | Encoder link | Syncs apply height and timing |

| Future robot | Open PLC I/O | Easier cell integration later |

When choices seem equal, ask to run your blanks. Real trials beat spec sheets. Bring poor-quality board too; a good demo proves stability on bad days.

Before you buy, confirm electrical and safety marks that your site or customers require. Typical targets include CE, UL or ETL for controls, and guarding that aligns with OSHA machine-safety rules. If you export, double-check voltage and plug standards.

Also review noise levels, air demand, and energy draw. A quiet, efficient unit keeps crews happy and lowers utility bills. Ask for a one-page spec plus a preventive-maintenance map so supervisors can plan service without guesswork.

Finally, request training materials in your team’s language and short video refreshers. Clear guides speed onboarding and keep daily checks simple.

Sources: Packaging education from PMMI.