Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Are you tired of packaging problems? Many factories face slow packaging lines. This causes delays. It also costs a lot of money. You might use too much plastic, like shrink wrap. Or maybe your team spends too much time bundling boxes by hand. This old way of packing creates waste, costs you money, and slows down your whole factory.

It gets worse. These small delays add up. A slow packaging line can stop you from growing your business. You might say no to big orders because you cannot pack them fast enough. Your workers might get tired from doing the same task over and over. And customers are demanding more green, sustainable packaging. Using too much plastic can make your brand look bad.

But there is a better way. The solution is banding. Banding uses one thin strip of paper or film to bundle and label your products. It is a smart, modern step that replaces old, wasteful methods. A high-quality banding machine automates this job. It makes your packaging line faster, cuts your labor and material costs, and delivers clean, recyclable packaging. It is a smarter choice than big boxes or plastic shrink wrap.

As a trusted partner in packaging innovation since 2005, Stars Creativity is dedicated to helping plants like yours. We build reliable and efficient packaging machinery to boost your production, reduce labor, and make packaging smarter and faster.

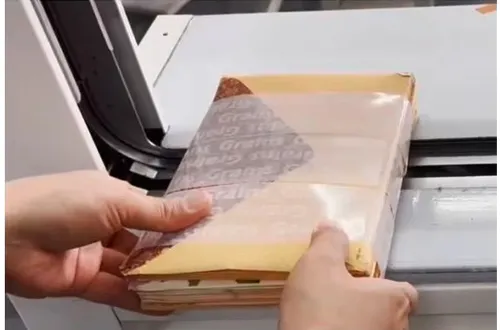

A banding machine is a simple but powerful piece of equipment. It wraps a single band of material, called a PP Strapping Band or paper band, around one or more items. It then seals the band tightly. This creates a secure bundle. Think of it as a clean, fast, and automatic way to tie your products together.

What Is a Banding Machine

For years, companies used other ways to bundle products.

Banding is different. It uses one small paper or film band. It is often sealed with ultrasonic banding technology, which uses sound waves, not heat. This is a huge change. Compared to shrink wrap, banding uses about 60% less material and up to 98% less energy. It creates much less packaging waste.

A banding machine can fit in many places on a packaging line.

Key Performance Indicators (KPIs) are numbers that show how well your factory is doing. Banding helps improve your most important packaging KPIs.

Throughput is how many products you can pack in one hour. Slow manual work or old machines cause micro-stops and slow you down. This hurts your Overall Equipment Effectiveness (OEE). Banding is very fast and automates this step, which is the best banding machine for improving packaging line speed.

Your machines need to be running to make money. This is called availability. Manual mistakes can cause your line to stop. An automatic banding machine makes perfect bundles every time. This reduces stoppages and keeps the line moving.

Are your workers doing boring, repetitive tasks? Automating these jobs with a semi automatic banding machine for small packaging lines or a fully automatic one frees up your team for more important work. It also reduces the risk of injuries.

Banding is a green technology. It uses less plastic. There are no glues. Paper banding machine for sustainable packaging lines offers an easy-to-recycle option. This helps you meet your sustainability goals and reduce disposal costs.

Manual bundling is a bottleneck. It is slow, and people make mistakes. Your entire packaging line can only move as fast as your slowest manual step. This leads to low output and high stress.

This bottleneck means you can’t get orders out the door fast enough. You might have to run extra shifts, which costs more in labor. You might even lose customers to factories that are faster and more efficient. It feels like you are always one step behind.

Replace that slow manual step with inline banding machine with print and apply label automation. A banding machine does the work of several people, but much faster and with no errors.

Picture your current line. Do you have workers putting products in bags or taping boxes by hand? Now, picture this: an infeed conveyor banding systems for continuous packaging feeds your products directly into an auto bander machine. The machine bundles them perfectly and sends them down the line. No one has to touch them. This is how you achieve packaging line optimization with banding machines.

Replace Manual Bundling with Inline Automation

The numbers prove it. A printing company improved its throughput by 60% after installing a banding machine. A pharmaceutical company saw its packaging line productivity go up by 25%.

Another test compared a shrink wrapper to an ultrasonic bander.

That is 3 times faster. This huge gain in OEE means you can make more money with the same production line.

You rely too much on manual labor for simple packaging tasks. Finding and keeping workers is hard and expensive. Repetitive tasks also lead to workplace injuries.

The cost of labor keeps going up. When a worker is injured, it costs even more in lost time and insurance claims. Your team is bored and unmotivated. This leads to lower quality work.

Use automation to reduce labor costs on packaging line with banders. An automatic strapping machine can do the work of several operators, allowing you to move your valuable team members to more complex jobs.

In one real-world example, a company went from needing three workers to secure loads down to just one. This is the kind of productivity gains after installing automatic banders you can expect. An automatic plastic banding machine works 24/7 without getting tired.

Automating the bundling process makes the workplace safer. There is no more heavy lifting, taping, or manual sleeving. This improves ergonomic improvements using automatic banding machines. A safer workplace means a happier and more productive team. This is how banding supports lean manufacturing in packaging.

Your packaging uses too much material. Shrink wrap, boxes, and plastic sleeves are expensive to buy and expensive to throw away. They also use a lot of energy.

This waste is eating into your profits. Every dollar you spend on packaging you don’t need is a dollar you lose. On top of that, your customers and governments are demanding you use less plastic. You risk fines and a bad reputation if you don’t change.

Switch to banding for huge material savings from switching to banding packaging. Banding uses a fraction of the material and energy.

The data is clear. Banding can reduce corrugate usage by banding multipacks. It often uses 60% to 80% less material than shrink wrap or sleeves. For every 1,000 packs you bundle, you could use just 0.4 kg of banding material instead of over 1 kg of shrink film.

This is one of the biggest benefits. A shrink tunnel needs to be very hot to work. It uses a lot of electricity. An ultrasonic banding machine uses up to 98% less energy. In one test, the shrink wrapper used 4.79 kWh of energy. The banding machine used only 0.09 kWh. This saves thousands of dollars on your energy bills.

Simpler packaging is cheaper to manage. A single paper band is easy to recycle. A product wrapped in multiple layers of plastic and cardboard is not. Minimize packaging waste using paper banding technology and make it easier for your customers to be green.

Your current packaging can damage your products. Tight straps can crush boxes. Shrink wrap can bend delicate items. It can also look messy.

Damaged products are a disaster. You have to replace them, which costs money. It also makes your brand look cheap and careless. A bad-looking package on the shelf will be ignored by shoppers.

Use banding to get secure bundling with low tension. Banding gives your products a clean, professional look that stands out.

A modern strapping system allows for precise tension control. You can set it to hold products securely without crushing them. This is perfect for low tension banding for delicate product packaging, like soft boxes or fresh food. It will minimize product damage with secure banding bundling.

A band is also a label. You can print logos, barcodes, and other information directly on it. This is called inline printer banders for branding and barcodes. It creates a clean, premium look that is much better than a plastic bag. This is perfect for film banding machines for retail packaging operations.

Secure bundles travel better. One berry company used pallet banding to stop their top layers of fruit from getting crushed during shipping. This is just one way strapping equipment can protect your products all the way to the customer.

You have many different products. You need to run small batches and change over your packaging line quickly. Old machines are slow to change.

Long changeover times are wasted time. Every minute your line is stopped, you are losing money. You can’t respond quickly to new orders or seasonal products.

Modern banding solutions for automated packaging lines are built for flexibility. They allow for fast changeover banding machines for short production runs.

With a modern strapping band machine, your operator can use a simple touchscreen to change settings. They can change the band tension or bundle size in seconds. This is perfect for co-packers or private-label projects.

Instead of buying thousands of pre-printed boxes for every product, you can use plain boxes and a printed band. The banding machine can print the barcode, lot code, or promotion right before it is applied. This saves a huge amount of money and waste.

Automatic Tabletop Paper Plastic OPP Film Banding Machine

The world is demanding greener packaging. Retailers, customers, and governments want you to use less plastic and create less waste.

If you don’t meet these demands, you could be fined. Big retailers might refuse to sell your products. Your brand could be named and shamed for being bad for the environment.

Banding is an eco friendly banding solution replacing plastic wrap. It is one of the easiest ways to meet your sustainability goals. Stars Creativity is an experienced banding machine manufacturer for high volume packaging that can help you make this change.

Switching to a paper banding machine for sustainable packaging lines is a powerful story. It shows you care about the planet. One seafood brand saved 400 tonnes of plastic per year by switching to banding.

New laws around the world are forcing companies to use less packaging. Because banding is so minimal, it helps you comply with these rules easily.

Banding is useful in almost any industry.

A new machine is a big investment. You need to know if it is worth the cost.

If you don’t do the math, you might miss a huge opportunity to save money. Or you might invest in the wrong equipment.

Calculate the Return on Investment (ROI). The ROI of investing in automatic banding machines is often very high, with payback in just over a year.

To calculate your ROI, look at:

Even a small improvement in OEE leads to big savings. In one case, a packaging line paid for itself in about 13 months just from OEE gains. When you add in labor and material savings, the payback period for a fully automatic strapping machine is often even shorter.

You have an existing packaging line. You are worried that adding a new machine will be difficult.

A bad installation can cause huge delays and headaches. If the machines don’t “talk” to each other, you will have constant jams and errors.

Plan the integration carefully. Work with an experienced partner like Stars Creativity. We have been building and customizing turnkey packaging line with integrated banding section solutions since 2005.

Look at the footprint and conveyor heights. Make sure there is enough space. A small footprint banding equipment for tight packaging areas might be the best choice.

The banding machine needs to connect to your line’s master control system (the PLC). This allows the machines to work together. It also lets you collect data for OEE analysis.

Always run tests with your actual products before you go live. This helps you find and fix any problems and prove the performance gains.

Answer these questions. If you say “yes” to most of them, you should seriously consider banding.

If you answered yes, the next step is simple. Evaluate one of your packaging lines. Let us help you run a cost comparison. You will see how a modern strapping packing machine from a trusted partner can transform your factory.