Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

You must pack more. You must pack faster. But there are many banding machines and strapping machines on the market. It is easy to buy the wrong one. Then lines stop. Packs break. Energy bills go up. Waste goes up.

The wrong banding equipment can use too much power, damage your product, or slow the whole line. Shrink tunnels can burn energy all day. Extra film and boxes add tons of plastic and cardboard each year. Operators struggle with complex controls. Service is slow. The result: higher cost per pack and unstable supply.

This guide shows a clear, step-by-step method to choose the right banding equipment. It uses real data, simple checks, and clear tables. You will see when to use banding vs strapping, how to select the right paper or plastic band, and how to read specs like speed, tension, and ROI.

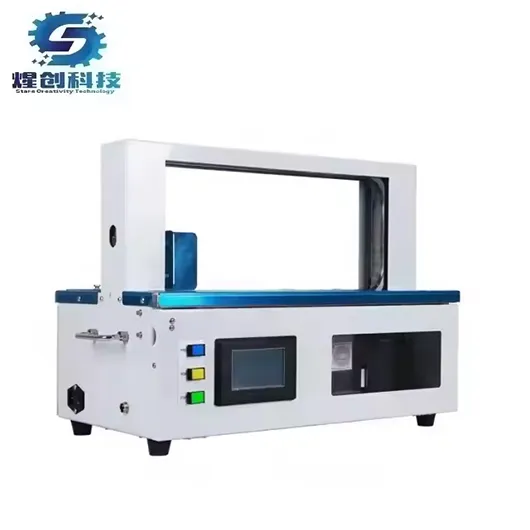

Qingdao Stars Creativity Technology Co., Ltd., founded in 2005, is one example of a maker that builds automatic banding machines and full lines for food, beverage, cosmetics, e-commerce, daily-use, electronics, and logistics plants. Their work in CE-certified, modular packaging machinery and exports to 80+ countries gives a good view of what modern banders must do in real factories.

Banding (also called bundling or paper banding) wraps a narrow paper or film band around products to hold them together. A banding machine feeds the band, tensions it, seals it (by heat seal or ultrasonic sealing), then cuts it.

Banding is used when you need:

Typical uses:

Banding is different from strapping.

Strapping machines (from brands like Mosca, Signode, EAM-Mosca, and others) pull a strap very tight around a load. They are made for heavy boxes, pallets, bricks, and lumber.

Use this simple rule:

banding machine working on packaging line

Before you look at any banding machines for sale, write down a simple list.

For each SKU, collect:

These points decide:

Ask:

Banding can both hold and label with one printed band. Makers like Bandall, ATS-Tanner, Felins, and Wexler Packaging offer systems where the band carries the barcode and logo, so you can drop separate labels.

Note:

This decides if you need:

Before you go deep into models, check if banding is the right technology at all.

Studies show that ultrasonic banding machines can cut energy use by about 98% and packaging material by up to 60% compared with shrink wrapping. (Sustainable Packaging News)

Why?

Table 1 – Banding vs Shrink Wrap (high-level)

| Item | Ultrasonic banding machine | Shrink wrapping line |

| Energy use | Up to 98% lower | High, tunnel must stay hot |

| Material per pack | Up to 60% less band vs film | Full film envelope |

| Pack look | Clean bands, full view of product | Glossy, but more plastic |

| Heat on product | Very low (ultrasonic) | High, can warp or melt |

| Line footprint | Compact | Tunnel + infeed + outfeed |

If you face high power costs or plastic taxes, these numbers alone can justify a switch to paper banding machine or plastic banding machine technology.

Use banding equipment when:

Use strapping equipment (PP or PET strap) when:

Plants often use both: banding systems upstream for retail packs and polypropylene strapping machines downstream for pallets.

Internal example links for strapping vs banding comparison on a real site:

These show where strapping systems sit in the line compared with automatic banding machines.

Automatic Carton Arch Strapping and Sealing Machine

You now know that banding is the right path. Next, pick the band material.

Ask:

Modern ultrasonic banding machines (from ATS-Tanner, Bandall, and others) can run very thin film (down to 35 µm) and special paper banding materials, which reduces waste volume and storage space for rolls.

On the Stars Creativity side, machines such as the automatic online paper and OPP film banding machine show how a single unit can switch between paper band and OPP film band, which is helpful for plants with many SKUs.

Use small tools when:

Pros:

Cons:

A tabletop banding machine is a compact unit. The operator places the product in the arch; the banding machine feeds, tensions, seals, and cuts.

Good for:

Example: an automatic 50 mm tabletop paper and OPP film banding machine can cover many small items with minimal floor space.

A fully automatic banding machine or auto bander machine can be built inline with conveyors and sensors. Packs arrive, are centered, banded, and discharged with no operator touch.

Use this level when:

Floor-type options, like an automatic floor-type paper and OPP film box bander machine, work well after case packers or carton sealers.

Automatic Tabletop Paper Plastic OPP Film Banding Machine

Once you know automation level and band type, compare machines by hard numbers.

Check:

If you run many SKUs, choose a bander with wide size range and quick changeover.

Vendors specify speed in bands per minute or cycles per hour. Make sure:

For delicate items:

For tougher bundles:

Look for:

This reduces training time and operator error.

Banding equipment does not work in a vacuum. It must fit your full packaging line.

Key questions:

Modern suppliers, including Stars Creativity, design modular, CE-certified banding equipment that can link with carton erectors, case sealers, and palletizers in food, beverage, cosmetics, e-commerce, and logistics plants.

Safe layout details:

Check:

Important points:

If your plant runs many shifts, service speed may matter more than a small price gap between two banders.

Do not look only at the banding machine price. Look at total cost of ownership (TCO).

Common ROI formula for packaging equipment:

ROI = (Annual net benefit ÷ Investment cost) × 100%

Where annual net benefit =

labor savings + material savings + energy savings − extra running costs.

Table 2 – Simple ROI example for a banding upgrade

| Item | Value (example) |

| Investment in new banding line | US$ 60,000 |

| Labor saved per year | US$ 20,000 |

| Material saved per year (less film) | US$ 12,000 |

| Energy saved per year | US$ 3,000 |

| Extra maintenance & parts per year | −US$ 5,000 |

| Annual net benefit | US$ 30,000 |

| ROI | (30,000 ÷ 60,000) × 100 = 50% |

| Payback time | 2 years |

Note how material and energy savings can be large if you move from shrink wrap to paper or film banding, thanks to up to 60% less material and 98% less energy use shown in industry data.

Sustainability rules and plastic-reduction laws are tightening world-wide.

Banding supports these goals because:

For food and pharma:

When you compare makers (such as ATS-Tanner, Bandall, Felins, regional OEMs, or Stars Creativity), do not start with price. Start with fit.

Ask for:

Stars Creativity is one example of a supplier that covers both banding and strapping across many industries:

These links show how one vendor can support a stand-alone banding unit or a full packaging line, which is useful when you plan long-term automation.

Use this simple checklist when you speak to suppliers:

Q1. What is a banding machine in packaging?

A banding machine wraps a narrow paper or film band around products to hold them together. It feeds, tensions, seals, and cuts the band in one cycle. It is often used for printed products, food packs, pharma boxes, and small cartons.

Q2. How is banding different from strapping?

Banding uses low-tension bands and focuses on product care and clean look. Strapping uses high-tension straps and focuses on load stability for boxes and pallets. Plants often use banders upstream and strapping machines downstream.

Q3. Does banding really save material and energy?

Yes. Industry data shows up to 60% less packaging material and about 98% less energy when you use ultrasonic banding instead of shrink wrapping.

Q4. How do I know if I should choose ultrasonic or heat-seal banding?

If your product is heat-sensitive or has a delicate surface, ultrasonic banding is safer. It puts energy only into the band, not into the product. For tougher packs, a simple heat seal banding machine may be enough.

Q5. What is the first step when talking to a supplier?

Come with a short data sheet: product sizes, weights, photos, current packaging method, and your main goal (speed, less plastic, better look, or all three). Then ask the supplier to suggest two or three banding solutions, from tabletop banders to fully automatic banding systems, and compare them using the ROI logic above.

This structure lets you explain how to choose the right banding equipment in a clear, data-based way, while still staying neutral and technical. You can now plug in your own plant numbers, work with trusted OEMs like Stars Creativity and others worldwide, and make banding a smart, efficient part of your packaging line.