Are your factory’s packaging costs going up? Do you spend too much on labor for manual bundling, only to get inconsistent results? You might use methods like shrink wrapping or strapping. But these can damage your products. They also use too much plastic and energy. This is a big problem.

This problem does not just stay on the factory floor. It agitates your entire business. High costs hurt your profits. Damaged products lead to unhappy customers and costly returns. Your packaging line becomes a bottleneck, slowing down growth. While you deal with these issues, your competitors are moving to smarter packaging automation. They are becoming faster and more efficient.

But there is a solution. It is called packaging automation with banding technology. This guide will show you how this technology works. You will learn what an automated banding system is, how to put it in your line, and how it gives you a great return on investment (ROI). This is a practical guide for buyers who want to understand how to choose and specify an automated banding machine.

What Banding Technology Is in Modern Packaging Automation

Banding technology packaging is a simple but powerful idea. It uses a single strip of paper banding or film banding to wrap one or more products. This creates a secure bundle. The band can be plain (unprinted banding) or have information printed on it.

Banding is a form of secondary packaging automation. It is mainly for unitizing items or creating retail-ready banding bundles. It is not for sealing the main product package.

Many people compare banding vs strapping machine comparison or banding vs. shrink wrap. Banding is often the better choice for gentle tension banding. It works well for:

- Fragile items: It does not crush or damage them.

- Minimal packaging bundling: It uses very little material.

- Easy open: Customers can remove the band easily without tools.

This focus on plastic reduction packaging makes banding a key part of building a sustainable packaging band strategy.

What Banding Technology Is in Modern Packaging Automation

How an Automated Banding Machine Works

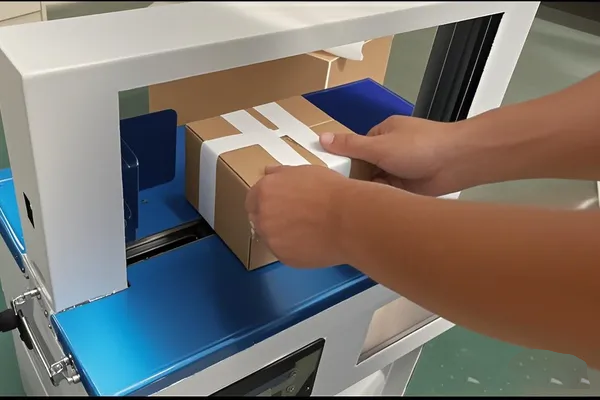

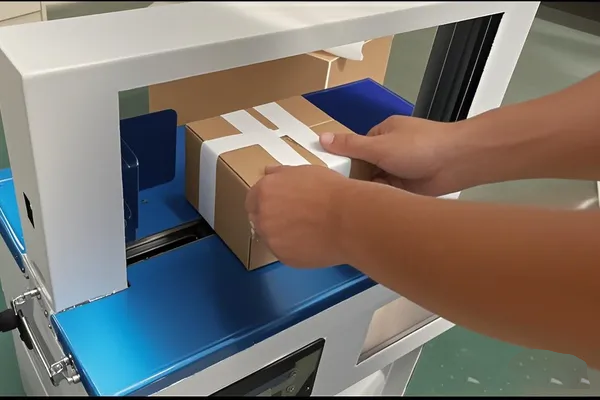

An automatic banding machine is a key piece of automated bundling equipment. The process is simple and fast.

Here is a step-by-step look at the cycle of an inline banding machine:

- Arch Formation: The banding machine forms the band material into an arch or loop.

- Product Entry: The product is moved into the arch. This can be done by a conveyor integrated bander or an operator.

- Tensioning: The machine applies gentle tension to the band. This can be variable tension banding or fixed length banding, depending on the need.

- Sealing and Cutting: The band is sealed using ultrasonic band sealing or a heat seal banding method. The machine then cuts the band.

- Discharge: The bundled product is moved out of the machine.

The machine cycle can be started in different ways. A photoelectric sensor activation or automatic cycle start sensor can start the cycle when a product is detected. For a semi automatic banding machine or a tabletop banding machine, an operator might use a footswitch. All of this is managed by a PLC controlled banding machine with an easy-to-use HMI touchscreen control panel.

The two main sealing methods are ultrasonic and heat sealing.

- Ultrasonic welding: This method from vendors like Felins uses high-frequency vibrations to create a strong, clean seal without heat or glue. This is great for ultrasonic weld consistency and uses less energy.

- Heat sealing: This method uses a heated element to weld the band. It is a reliable technology, often seen in machines from suppliers like ATS-Tanner and Bandall.

Where Banding Fits in a Packaging Automation Line (Integration Map)

A banding machine can be a standalone unit or part of a fully automatic banding line. The key is successful packaging line integration.

Here are common places for a bander in an end of line packaging automation setup:

- After Collation: Bundles products after they have been counted and grouped. This is used for OTC multipack banding or pharma box banding.

- After a Cartoner: Groups several cartons together.

- Before a Case Packer: Stabilizes a group of products before they are packed into a larger box.

- At a Kitting Station: Combines different items for e-commerce fulfillment bundling.

Successful automation retrofit banding requires careful planning. Here is an integration checklist:

- Line Flow: Use an indexing conveyor to bander or conveyor accumulation before banding to ensure a smooth flow. A pusher feeder into banding machine can help position products correctly.

- Product Handling: You may need product squaring for banding to make sure bundles are neat. A robotic pick and place banding system can handle complex tasks.

- Controls: The bander’s PLC must “talk” to the main line controller. This involves PLC handshakes, sharing sensor data, and managing fault states. Key hardware may come from brands like Siemens SIMATIC, Rockwell Automation (Allen-Bradley), Schneider Electric, or Omron.

- Safety: Safety guarding banding equipment is critical. All equipment must be CE compliant packaging machinery.

Paper Banding vs. Film Banding (And How to Choose Fast)

Choosing between a paper banding machine and a film banding machine is a key decision.

- Paper Banding: Often made from recyclable paper band material like kraft paper banding. It is perfect for branding and telling a “plastic reduction” story. It is ideal for lightweight bundling and is popular in the print finishing banding industry for bundling stacks of paper.

- Film Banding: Uses materials like BOPP banding film or a polypropylene (PP) band. Film is strong, moisture-resistant, and offers a glossy look, making it a good fit for frozen food film banding and cosmetics gift set banding.

How to choose? Look at these factors:

- Product: Is the surface delicate or slippery?

- Environment: Will the product be in a hot, cold, or humid place?

- Tension: How strong does the bundle need to be?

- Printing: Do you need to print on the band?

- Rules: Are there rules about packaging for your product?

Paper Banding

“Branding with Banding”—Printing, Labeling, and Traceability in One Step

Modern banding is also a banding and labeling system. You can print information directly on the band. This is a huge advantage. It can eliminate the need for a separate label applicator.

This is often done with a banding with thermal transfer printing (TTP) system. A thermal transfer printer (TTP), like the kind found on an ATS US-2500 TTP, can print:

- Barcodes on band or a QR code printed band.

- Dates and lot numbers for traceability banding.

- Promotional messages for multipack promotion banding.

This ability is critical for track and trace packaging and serialization for pharma bundles. It helps ensure product safety and authenticity. A barcode scanner or vision inspection after banding can verify the data.

Best-Fit Applications (Industry Use Cases)

Banding is used in many industries. Here are a few examples:

- Food & Produce: An automatic plastic banding machine is often used for bakery product banding and as a produce banding wrap alternative. It keeps items fresh and looks great on the shelf.

- Pharma & Health: A box bander machine can be used for medical device bundling. Tamper evident banding adds security.

- Printing & Graphics: Gentle tension banding is perfect for bundling delicate printed materials like cartons, sleeves, and tickets.

- E-commerce & Kitting: Subscription box bundle banding helps with kitting and bundling automation. It reduces the need for void fill and extra boxes.

How to Spec a Banding Automation System (Buyer Checklist)

Ready to look for banding machines for sale? Here is a checklist to help you specify the right industrial banding equipment.

- Speed: What is your throughput target in units per minute? How many hours a day will it run?

- Product Size: What are the min/max dimensions of your bundle? You need to know the right band loop size adjustment.

- Tension: Do you need low tension for delicate items or high tension for heavy ones?

- Band: What band width selection do you need? Common sizes are 20mm banding, 30mm banding, and 50mm banding. Wide banding for delicate products is a good option.

- Setup: Do you need an inline vs standalone machine? A conveyor-fed system or an operator-fed automatic banding machine?

- Service: Ask about banding machine spare parts, preventive maintenance bander schedules, and remote support. Uptime improvement packaging line is the goal.

A trusted supplier can help you with this. For example, Stars Creativity has specialized in customizing automatic packaging equipment since 2005. With a 3,000㎡ facility and experience in over 80 countries, they can engineer a modular banding system for any need, whether it’s a standalone unit or a complete auto bander machine integrated into your line.

How to Spec a Banding Automation System

ROI and Cost Drivers (What Actually Changes Your Payback)

The return on investment for a banding technology packaging system is strong.

Here are the costs to consider:

- The machine itself (e.g., an ATS US-2000 or a fully automatic strapping machine for comparison).

- Packaging line integration costs.

- Consumables cost optimization for paper or film bands.

- Labor.

- Downtime.

But the savings are significant.

- Material Reduction: Banding uses much less material than shrink wrap or boxes. It is a great alternative to shrink wrap bundling.

- Labor Savings: Automated bundling reduces the need for manual labor.

- Damage Reduction: Low tension unitizing prevents product damage.

- Efficiency: High speed banding and high throughput bundling improve your Overall Equipment Effectiveness (OEE).

Evidence of Performance

Data from real-world tests show how powerful these savings can be.

| Evidence |

What was measured |

Data point(s) |

| 1-hour test (banding vs. shrink) |

Double packs of small boxes |

Banding: 680 pcs/h, 276 g material, 0.06 kWh energy. Shrink: 221 pcs/h, 713 g material, 3.26 kWh energy. [1] |

| Vendor claim |

Ultrasonic banding vs. shrink |

Up to 98% less energy and 60% less packaging. [2] |

| Case study (AMAB) |

Switch from shrink to banding |

Reported 80% reduction in plastic consumption. [3] |

| Case study (TR8COMM) |

SIM card bundling |

“We use less material, the process is faster, and we need fewer hands.” [4] |

As one report noted, many customers see an ROI in 12 months or less. [5] This makes the total cost of ownership banding system very attractive.

Common Implementation Pitfalls (and How to Avoid Them)

To get the best results, avoid these common mistakes:

- Poor Product Handling: If products are not stable or aligned, you will get bad bundles.

- Wrong Material: Using a paper band in a wet environment will cause problems.

- Wrong Machine Size: An arch that is too small will not work.

- No Bypass Plan: What happens if the bander needs maintenance? You need a plan to keep the line moving.

- Forgetting Safety: Always plan for proper safety guarding.

Maintenance and Reliability Basics

A reliable automated banding system requires basic care.

- Daily Checks: Clean rollers, the sealing head (ultrasonic or heat), and sensors from brands like SICK.

- Seal Quality: Regularly check the weld quality monitoring and band overlap control.

- Consumables: Store band rolls correctly. Train operators on fast band roll replacement to minimize stops. Refer to banding machine troubleshooting guides.

FAQs

- What is banding in packaging and how is it different from strapping?

Banding uses a wide, gentle paper or film band. A strapping machine uses a strong, thin plastic strap and is better for heavy-duty jobs. [3]

- Is paper banding strong enough for multipacks?

Yes. For many products like carton bundling banding or folded carton bundle banding, a paper band is very strong.

- Ultrasonic vs heat seal banding: which is better?

Ultrasonic is faster, uses less energy, and creates no fumes. Heat sealing is a very reliable and proven technology. The best choice depends on your needs.

- Can I print barcodes or dates directly on the band?

Yes. Using a thermal transfer printer (TTP) allows for printing variable data directly on the band.

- What products are best for inline automated banding?

Products that need to be bundled gently, have high volume, and require a clean, retail-ready look are perfect for an automatic arch banding machine.

- How do I estimate banding machine speed and ROI?

Measure your current throughput and costs. Then, consult with a machine supplier. They can provide machine speed specs (e.g., up to 38 cycles/min) and help calculate your potential savings on material, labor, and energy. [6]

Conclusion: Your Next Step to Smarter Packaging

You face the problem of slow, costly, and wasteful packaging. This agitates your business by hurting profits and efficiency. The solution is clear: packaging automation with banding technology.

As we have seen, banding offers huge benefits:

- It is gentle on products.

- It is efficient, saving material, energy, and labor.

- It is flexible, integrating into any line and even handling printing.

The key is to partner with an expert who can deliver a reliable, customized solution. A company with deep manufacturing experience, like Stars Creativity, can design and build the exact strapping equipment or banding system your factory needs. They provide CE-certified, modular machinery to boost your production and make your packaging smarter.

Ready to see what banding can do for you? Send your product dimensions and target speed to get a custom line layout, a band material recommendation, and a free ROI estimate. Take the first step toward faster, leaner, and more sustainable packaging today.