Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Is your team wasting hours hand-wrapping pallets? Are you seeing damaged goods when shipments arrive? Do you throw away too much stretch film?

These problems cost you time, money, and customers. When pallets fall apart during shipping, products break. When workers wrap pallets by hand, they get tired and hurt their backs. And all those rolls of stretch film you use? They cost more than you think.

But there’s good news. The right pallet stretch wrapper machine can fix these problems. Let’s look at how.

A pallet stretch wrapper is a machine that wraps plastic film around boxes on a pallet. This keeps items from falling off during shipping.

These machines work better than people wrapping by hand. They make pallets more stable. They use less film. And they free up workers to do other jobs.

All stretch wrappers do one main job – they put film around a pallet. But how they do it can be different:

The best part? This happens with little or no help from people.

Not all pallet wrappers work the same way. Let’s look at the main types:

In a turntable wrapper, the pallet spins on a round base. A roll of film moves up and down a pole next to it.

Why pick this type?

Stars Creativity’s semi-automatic pallet wrapping machine uses this trusted design to give you great results with less work.

Turntable Stretch Wrappers

With rotary arm wrappers, the pallet stays still. An arm with the film spins around it.

Why pick this type?

Ring wrappers put a circle of film around items moving on a belt.

Why pick this type?

Stars Creativity’s horizontal stretch wrap machine is made for these special jobs.

Not all stretch wrappers are the same. The best ones have these important parts:

This part of the machine pulls the film before it goes on the pallet. It makes the film thinner but stronger.

Why it matters:

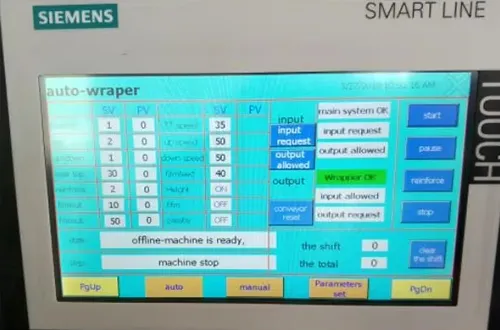

Smart machines can tell what they’re wrapping and change how they work.

Why it matters:

The best machines need less help from people.

Why it matters:

Automation Features

Look at these numbers to see why good wrappers are so important:

|

Wrapper Type |

Pallets Per Hour |

Labor Savings |

|

Hand Wrapping |

5-10 |

0% |

|

Semi-Auto |

15-30 |

50-70% |

|

Fully Auto |

60+ |

90-100% |

Real companies see real results. A tool company in South Dakota switched to an automatic pallet wrapper and:

Throughput & Labor Savings Comparison

75%

Film Savings

6 Months

Average ROI

60%

Less Damage

Want to get the most from your machine? Try these tips:

Too loose? Loads fall apart. Too tight? Film breaks. Just right? Stable loads with less film.

Best practices:

How the film goes on matters a lot!

Things to set:

Dirt and broken parts make bad wraps.

Maintenance checklist:

Not every place needs the same wrapper. Here’s how to pick:

Big warehouses that ship lots of boxes need:

Places with cold rooms need special features:

Ask these questions before you pick a wrapper:

About your loads:

About your space:

About your needs:

The pallet wrapper market keeps growing:

Most machines can wrap different sizes if they have:

Can one machine wrap all pallet sizes?

A good pre-stretch system can:

It depends on your numbers:

Research shows that good wrapping matters:

Stars Creativity’s stretch wrap equipment is built on these scientific principles to give the best load stability with the least amount of film.

Changing from hand wrapping to machines makes a big difference:

Labor savings:

Film savings:

Load quality:

The best wrapping is part of a complete system. Stars Creativity’s pallet wrapper works with other machines like:

This makes a full system that packs, seals, and wraps with little help from people.

The global market for pallet wrappers grows each year because smart companies see the value. With the right machine, you can:

When you look at the numbers, pallet stretch wrapper machines aren’t a cost – they’re an investment that pays you back every day.

For any size business, from small shops to big plants, the right wrapper makes shipping better. And as we’ve seen from the data, that means more profit, happier customers, and less waste.

When you’re ready to stop wasting film, time, and money on old wrapping methods, the solution is clear – a pallet stretch wrapper machine that fits your needs.