Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Slow packing lines, messy pallets, and tired staff are common headaches in busy logistics hubs. Hand banding and taping waste time and materials. A banding machine gives you clean, fast, repeatable bundles so your team works smarter, not harder, and your customers receive neat, damage-free goods.

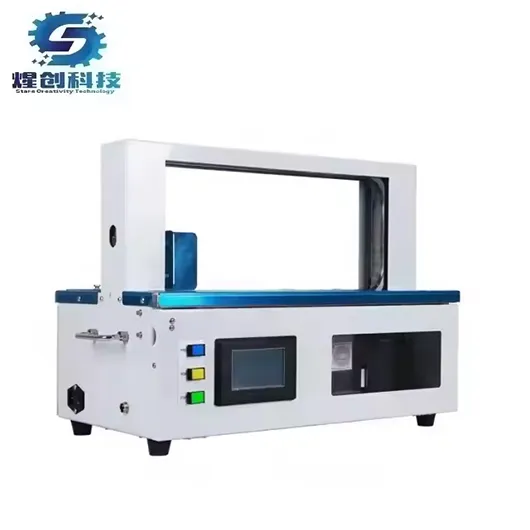

A stand alone banding machine for logistics is a compact, self-contained packaging solution that wraps a paper or plastic strap around a bundle, then seals and cuts it in one step. It replaces slow hand tools, stabilizes mixed-size products, reduces packaging material costs, and keeps parcels securely together for transport and storage.

As a professional manufacturer of automatic packaging machines, we describe a banding machine in simple terms: it is a compact unit that loops a flat banding material around products, tightens it, seals it, and cuts it. Unlike taping or shrink-wrapping, the banding process focuses on holding items together with minimal material.

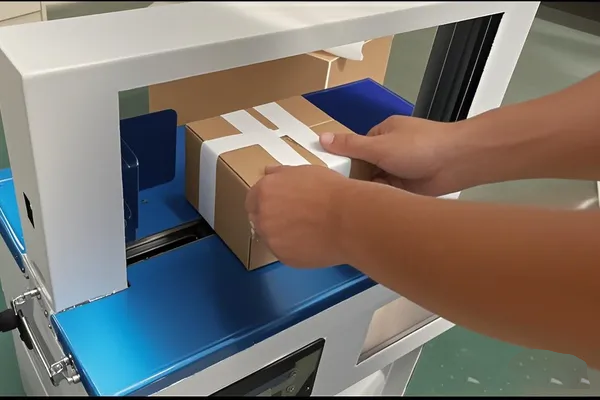

In a logistics center, you place a parcel, stack of leaflets, or small carton in the banding arch. The machine feeds the strap around the load, closes the loop, and ejects a neat bundle. This can happen at the end of a packaging line or as a stand-alone unit next to a workstation.

Banding machines use paper or film bands to group items for easier handling. They are common in the packaging industry and in a wide range of industries such as logistics, printing, food, and e-commerce. With simple controls and ergonomic banding tools, even new staff can learn the workflow in minutes.

What is a banding machine in logistics?

Many logistics teams ask whether they really need a banding machine or if a strapping machine is enough. Both are banding and strapping machines designed for industrial packaging, but they serve different packaging goals. Strapping uses narrow plastic strapping pulled to high tension, mainly for securing heavy crates or pallets.

A stand alone banding machine usually applies wider, gentler plastic bands made from paper or film. It is ideal for light to medium loads, mixed-size goods, and delicate printed items. Compared with traditional packaging methods like hand taping or tying with string, banding is cleaner, faster, and easier to remove.

Compared with manual strapping tools, a banding machine requires less force and less training. Operators simply position the products, press one button, and the machine handles the tension, sealing, and cutting. This reduces the need for manual effort, improves ergonomics, and standardizes the appearance of every bundle leaving your dock.

As warehouse volumes grow, you cannot rely on slow, inconsistent hand work. An automatic banding machine turns a repetitive job into a fast, consistent packaging tool. With automatic banding or even fully automatic systems, the operator just loads products while the machine controls tension, sealing temperature, and cycle time.

This improves packaging efficiency dramatically. In many sites, we see a single banding machine replace two or three workers with tape dispensers. You get efficient packaging, fewer rework loops, and less damaged product. Because the machine repeats the same cycle each time, you also improve packaging quality and traceability.

Automation also protects your budget. An optimized packaging process uses only the amount of banding material needed. That lowers your spend on materials and cuts time lost to re-doing loose or crooked bands. Over a year, this can free up labor for tasks that add real value, such as quality checks or kitting.

When you compare banding machine features, it helps to start with the basics. First, look at the arch size, sometimes called the banding arch. This is the open frame through which the band travels. It defines the maximum product size your banding machine can handle in one run.

Next, check the available band widths and banding material options. Common widths range from 20–60 mm, with a range of banding tensions to suit light leaflets, cartons, or small boxes. Wider bands spread the pressure, so they are gentler on delicate products and provide more space for printing your brand or barcodes.

Finally, look at the control panel and safety machine features. Good banding equipment lets you store presets for different bundle sizes, shows alarms clearly, and is easy to clean. For multi-shift operations, features such as auto-loop ejection, error logs, and remote support interfaces can save hours of troubleshooting every month.

Example: compare methods by speed and labor

| Method | Typical banding speed (bundles/hour) | People needed | Material use per bundle |

| Hand taping | 80–120 | 1 | High |

| Hand strapping with tools | 150–200 | 1 | Medium–high |

| Semi-automatic banding | 400–600 | 1 | Low |

| Stand alone banding machine | 700–1,200 | 1 | Very low |

These figures are typical values we see in real projects, and they show how quickly a modern bander can pay back in labor and material savings.

Automatic Tabletop Paper Plastic OPP Film Banding Machine

In the market you will find several banding machine types. The main types of banding machines are semi-automatic banding tables, stand alone banding units, and fully automatic banding machines integrated into conveyor lines. You can also choose compact, portable banding units for small spaces or occasional jobs.

Each group includes different banding machine models with options such as conveyor in-feed, print-on-band, and stainless-steel frames for wet areas. For logistics, most customers choose stand alone machines that operators can wheel to the busiest lane. Later, these can be linked to a small conveyor to form a simple cell.

Large facilities often combine several machines into flexible banding systems. For example, you might place an in-line bander after weighing, then another before palletizing. By adding sensors and simple PLC logic, you can route work to the right machine and keep your production line balanced, even as order patterns change.

Well-designed, modern banding machines do more than just hold products together. They stabilize loads, standardize work, and give supervisors real-time data. In busy packaging operations, a stable banding machine helps you keep takt time under control and avoid bottlenecks around labeling, weighing, or manifest printing.

A good machine also protects packaging quality. Every band is placed in the same position, with the same tension and look, no matter who is on shift. That means consistent packaging quality across all routes and customers. When cartons arrive neat and aligned, your logistics brand looks more reliable and premium.

This is the heart of efficient banding in a modern packaging flow. You move from reactive fire-fighting to stable, predictable work. For our customers, the result is usually fewer claims, fewer transport damages, and fewer surprises at the end of the month when they audit returns and rework.

How modern banding machines improve packaging operations

Today, logistics managers care about sustainable packaging as much as speed. A banding machine can support sustainability goals because it uses far less material than full shrink-wrap or heavy cartons. In many food packaging lines, customers use narrow paper bands instead of full cardboard sleeves to reduce weight and packaging waste.

You can choose paper banding, paper and plastic combinations, or ultra-thin films depending on your risk and marketing needs. Some brands even use paper or film bands as mini billboards, adding logos and messages for branding by banding. This gives you sustainable and efficient packaging without losing shelf impact.

From our view as a manufacturer, banding technology is a leader in sustainable packaging solutions for many routes and packaging environments. When you use paper instead of full boxes, you cut corrugated usage and transport emissions. Over thousands of orders, the material savings and lighter trucks add up to more sustainable packaging operations.

Compared with traditional packaging like full corrugated outers and heavy tape, clever banding can cut both material use and labor time. That is why more logistics teams are rethinking their flow and adding banders as a core part of their packaging solution roadmap.

When we help a new client, we start by mapping their packaging needs and packaging requirements. We look at product sizes, weights, daily order volume, and existing conveyor layout. Then we recommend a banding machine with suitable band widths, arch size, and controls so it can handle both today’s work and tomorrow’s growth.

A simple way to plan is to list your main SKUs and note the smallest and largest bundle you must handle. Add information about labels, fragile items, and any compliance rules. With that, we can define a variety of banding recipes and suggest machines that can grow with your warehouse or hub.

Remember that a bander must also fit your warehouse layout and different packaging flows. Some sites favor single-lane cells; others need high flexibility for many sectors and products. Our job as a supplier is to optimize your packaging so the machine supports operators instead of getting in their way.

One 3PL client handled thousands of small parcels per hour. They used hand tape, some manual banding, and stretch film. Labor costs were high and the line could not keep up at peak. We proposed an automatic banding cell with two machines side by side on the main production line.

Each banding machine had an oversized arch and custom guides, so operators could feed mixed cartons quickly. With this setup, they reached high-volume packaging of more than 1,200 bundles per hour. The machines delivered a stable packaging solution without adding extra staff, even during holiday surges.

In this project we compared several advanced banding machines, including global names like Bandall and ATS. It is not always necessary to buy the world’s best-selling banding machine or the latest best-selling banding machine model. What matters is matching banding machine technology to your real workload, budget, and maintenance skills.

In the end, the client chose a robust unit with ultrasonic banding machines sealing head instead of heat. This advanced banding method works well for sensitive films and labels. After three months, the site reported lower rework, less film damage, and happier operators because the banders were quiet and easy to set up.

What products can I bundle with a banding machine in logistics?

You can bundle small cartons, mailers, leaflets, magazines, trays, and lightweight boxes. A banding machine is flexible enough to handle mixed heights and widths, as long as they fit inside the arch. For heavier loads or pallets, you may still combine banding with other methods such as stretch wrapping.

Is a stand alone banding machine hard to install and operate?

No. Most stand alone banding machines arrive pre-configured. You connect power, load the banding material, and follow a short training session. Operators usually learn to position the load, press the button, and remove the finished bundle within minutes. There is no need for complex programming or special tools.

Can a banding machine use paper or plastic bands?

Yes. Depending on your project, we can provide banding machine setups for paper or plastic bands. Paper is ideal for eco-focused brands, while thin film bands suit damp areas and tougher packaging environments. Both handle a range of banding tensions and can be printed with your logo or barcode.

How does a banding machine help reduce packaging waste and costs?

Because the banding process uses only a narrow strip of material, you can replace full boxes or wide tape in many jobs. This reduces packaging waste, cuts packaging material costs, and removes unnecessary layers. Over time, many clients see banding as one of their strongest banding solutions for cost and sustainability.

Do I still need other banding tools if I invest in advanced banding machines?

Most sites keep a few simple banding tools or tape dispensers for unusual items. However, the core work should move to your advanced banding machines. That way, you keep critical orders flowing through standardized, safe, and traceable equipment while manual work is only used as a backup.

What support can I expect from a professional manufacturer of automatic packaging machines?

As a specialist in banding machines use and other automatic systems, we help you design the cell, choose banding machine models, test your products, and train your staff. After installation, we support you with spare parts, remote troubleshooting, and advice on how to improve packaging performance as your volume grows.

Because we are a professional manufacturer of automatic packaging machines, we do more than sell hardware. We look at your whole packaging process, from inbound sorting to outbound shipping, and tailor banding solutions to your real flow.

When we design a system, we focus on:

Our goal is to be your long-term partner, not just a box seller. If you are planning a new hub or upgrading an existing line, we can help size, specify, and deliver the right banders, from simple tables to fully automatic banding machines.

If you are ready to upgrade from tape and hand tools to smart, sustainable and efficient packaging, a well-chosen stand alone banding machine could be the quiet hero of your next logistics project.