Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

When warehouse teams battle shifting loads, rising labor costs, and damaged shipments, frustration mounts. Missed deadlines and wasted film only make matters worse. What if there were a better way? The right stretch wrapping equipment can secure your pallets, boost efficiency, and reduce risk, transforming how your business handles every shipment.

Stretch wrapping equipment automatically applies stretch wrap film to pallets, stabilizing loads for shipping and storage. It protects goods, increases throughput, and reduces material costs by streamlining the pallet wrapping process compared to manual methods.

Stretch wrapping equipment—sometimes called a stretch wrap machine or stretch wrapper—is specialized packaging equipment designed to apply stretch film securely and efficiently around palletized goods. These machines are essential in any modern logistics, warehousing, or manufacturing operation where stability, safety, and throughput are top priorities.

A typical stretch wrap machine uses a turntable or rotary arm. The load sits on the platform, and the film carriage stretches and wraps the film tightly around the pallet. The pre-stretch mechanism ensures the film adheres snugly, minimizing waste and maximizing load integrity. In high-volume environments, automatic stretch wrappers connect to conveyor lines for seamless, hands-free operation.

Expert Quote:

“Switching from manual to automatic stretch wrapping cut our film use by 35% and nearly eliminated load damage.”

—J. Smith, Plant Manager, Global Logistics Co.

| Criteria | Manual Wrapping | Automatic Stretch Wrapping Equipment |

| Throughput (loads/hour) | 10–15 | 40–80+ |

| Film Waste | High | Low (Pre-stretch: up to 300%) |

| Labor Required | 2–3 operators | 0.5–1 operator |

| Load Security | Variable | Consistent |

| Operator Fatigue | High | Low |

| Material Cost Savings | Minimal | 25–50% savings per year |

Stretch wrap is the backbone of secure shipping and storage in today’s fast-paced supply chain. For B2B buyers in manufacturing, logistics, and e-commerce, stretch wrapping equipment is more than a convenience—it’s a competitive necessity.

Industry Fact:

According to Packaging Strategies, companies that implement automatic stretch wrappers report up to 50% lower film costs and 80% fewer load damage incidents.

Choosing between automatic and semi-automatic stretch wrap machines depends on your business’s size, throughput, and packaging needs.

Automatic stretch wrappers are fully integrated solutions designed for high-speed, high-volume operations. They can process 40–80+ pallets per hour, require minimal human intervention, and offer programmable wrapping cycles.

Applications: Distribution centers, beverage bottlers, large manufacturers, and 3PL providers.

Semi-automatic stretch wrap machines are ideal for medium-volume businesses or those with varied load sizes and shapes. Operators position the pallet and start the cycle; the machine manages the wrap tension and rotation.

Tip:

Semi-automatic stretch wrappers are ideal for warehouses with lower volume, seasonal spikes, or varied pallet types.

Case Study:

A mid-sized e-commerce warehouse increased throughput by 40% and cut film waste by 30% after switching from hand-wrapping to a semi-automatic stretch wrapping system.

Not all stretch wrapping equipment is created equal. Leading manufacturers offer a range of features to maximize performance and ROI.

Did you know?

The latest stretch wrapping systems can achieve film stretch rates up to 300%, making every roll go further and protecting more products with less material.

| Stretch Wrapper Type | Application Scenario | Throughput | Typical Industry |

| Turntable Stretch Wrapper | Standard, stable pallet loads | 20–40/h | Manufacturing, Warehousing |

| Rotary Arm Stretch Wrapper | Heavy, unstable, or tall loads | 30–60/h | Beverage, Food, Pharma |

| Horizontal/Orbital | Long or odd-shaped products | 10–25/h | Construction, Carpentry |

| Robotic Mobile Wrapper | Multiple locations, low volume | 8–18/h | E-commerce, Distribution |

Selecting the ideal stretch wrapping equipment for your business involves understanding your load types, throughput requirements, space constraints, and desired automation level.

Quote from our expert:

“The right stretch wrapper transforms not just your packaging line, but your entire shipping and inventory process.”

—L. Chen, Chief Engineer, Stars Creativity

Let’s break down the real savings automatic stretch wrapping equipment can deliver.

Here’s a quick example for a mid-sized operation:

| Scenario | Hand Wrapping | Semi-Automatic Stretch Wrapper | Automatic Stretch Wrapper |

| Pallets/day | 120 | 120 | 120 |

| Film used/pallet | 2.8 kg | 1.6 kg | 1.3 kg |

| Annual film cost | $39,000 | $22,300 | $18,300 |

| Labor (annual) | $25,000 | $9,800 | $6,200 |

| Total 5-yr cost | $320,000 | $161,000 | $123,000 |

Chart: Film Usage by Wrapping Method

| Wrapping Method | Film Usage (kg/pallet) |

|———————|———————–|

| Hand Wrapping | 2.8 |

| Semi-Auto | 1.6 |

| Fully Automatic | 1.3 |

Key Fact:

Automatic and semi-automatic stretch wrappers can reduce film consumption by up to 50%, slashing annual packaging costs and supporting sustainable operations.

Stretch wrapping equipment is widely used in:

For unique needs, horizontal stretch wrap machines or custom packaging solutions are available.

See our horizontal stretch wrap machine for long products and our box wrapping machine for cartons.

Modern production demands seamless integration. Today’s stretch wrapping systems easily connect with:

Integration streamlines workflow, enables real-time data tracking, and minimizes bottlenecks. Many customers start with a semi-automatic stretch wrap machine, then upgrade to a fully automated line as throughput grows.

Pro tip:

A professional packaging equipment manufacturer can tailor your integration—ask about “plug-and-play” compatibility, custom turntable options, and remote diagnostics.

Routine maintenance is key for high productivity and long machine life.

Recommended practices:

Our commitment:

As a professional stretch wrap machine manufacturer, we provide 24/7 technical support, rapid spare parts delivery, and comprehensive user training—helping you achieve consistent uptime and maximum ROI.

How much film does a stretch wrapper save versus hand-wrapping?

Stretch wrap machines with pre-stretch tech typically use 30–50% less film per pallet than hand wrapping, leading to thousands in annual savings.

What’s the lifespan of a typical stretch wrap machine?

With proper maintenance, high-quality machines last 7–12 years or more.

Can stretch wrappers handle odd-shaped or unstable loads?

Yes. Rotary arm and mobile robotic stretch wrappers are designed for heavy, tall, or unevenly shaped loads. See our robotic stretch wrapper.

Is operator training complex?

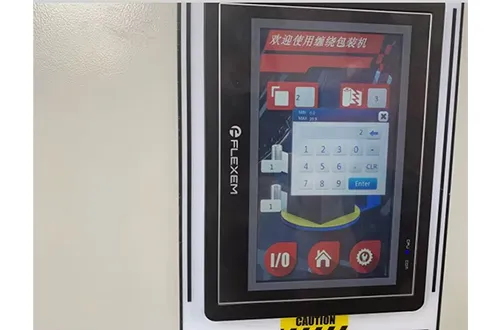

Not at all. Most semi-automatic stretch wrap machines are easy to use, with clear touchscreens and pre-set programs.

Our factory provides step-by-step online and on-site training.

How soon can you deliver and support equipment globally?

We offer fast international delivery and 24/7 remote support. Spare parts are shipped within 48 hours, with technical help always available.

“We help clients optimize packaging efficiency, reduce costs, and meet the world’s toughest shipping demands.”

— Stars Creativity Engineering Team

Want to slash packaging costs, boost throughput, and ensure every pallet is secure?

Contact us now for a free, expert consultation—or chat with our engineers live!