Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

If scattered packages, disorganized bundles, and unpredictable damage have ever frustrated you, you’re not alone. Packaging chaos can derail efficiency and increase costs. Fortunately, a banding machine solves these headaches by bundling goods neatly, quickly, and without causing harm, bringing consistency and calm to any workspace.

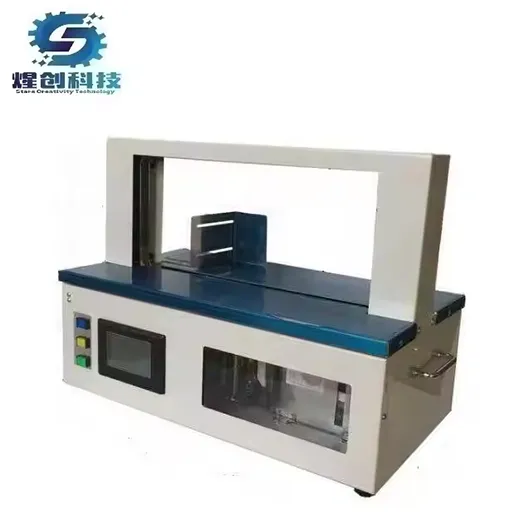

A banding machine—also known as a strapping tool—wraps a banding material around products to securely hold items together. By maintaining precise tension and applying a dependable seal, it ensures a bundle stays intact. This eliminates the need for manual strapping tools and shortens your production line, reducing labor costs while delivering a professional finish every time.

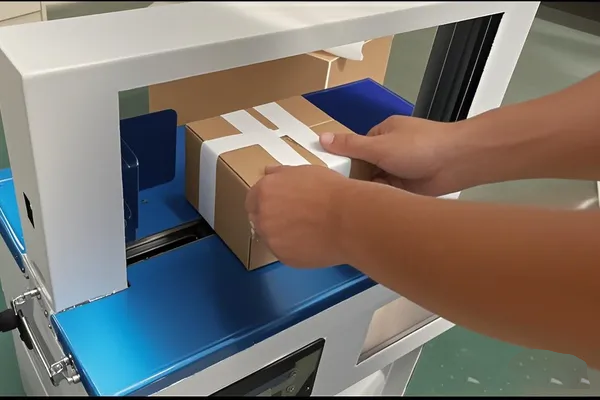

banding machine usage

If you oversee production in a warehouse, manufacturing facility, or distribution hub, nothing catches your eye faster than organized, damage-free parcels efficiently leaving your floor.

What’s behind this efficiency?

The banding machine applies a wide range of materials—such as paper, polyethylene, or plastic film—around your products. This machine applies consistent force, guaranteeing that even a large bundle of products remains intact. Whether you run a massive assembly center or a smaller workshop, a well-chosen banding machine can transform chaos into clarity.

Why does it matter?

Attention to detail matters. Careless bundling can slow shipping schedules, produce returns, and frustrate customers. When you incorporate an automated banding machine, each package is stabilized and sealed with uniform tension, which significantly reduces the chance of mishaps. If you’re looking for order, speed, and dependability, it’s worth exploring how these machines function to capture attention right at the start of the packaging process.

A strapping machine fuels intrigue by showcasing consistent wrapping quality, streamlined machine work, and reduced reliance on error-prone manual labor. This is where real fascination builds—seeing how quickly you can ship products with zero damage.

A look at the machine’s operation

A strapping machine—whether semi-automatic or fully automated—uses a strap (fabric, plastic, or composite) to hold objects or boxes together. Through a calibrated tensioner, the system controls the tightness of each seal. This calibration is vital for guaranteeing protection but without the need for manual adjustments every time.

Key benefits

As interest grows, you’ll see how such automation secures each bundle neatly, ensuring minimal downtime and consistent throughput.

For those intrigued by broader possibilities, an edge banding machine offers a specialized application in woodworking machinery. If your products include cabinetry or furniture, edge sealing is essential to achieve a high-grade finish and to protect the edge from moisture or impact. Traditional banders, by contrast, wrap a banding material around boxes, stacks, or other items needing bundling.

Key differences

Where they overlap

Both types use controlled tension to accomplish a reliable seal. Both can be part of advanced automation lines that accelerate your packaging or finishing tasks. And both rely on robust mechanical designs that let you run high-volume operations with minimal downtime.

If an organization yearns for efficiency, reliability, and durability in bundling or finishing tasks, an automated banding machine is the ticket to sustained excellence.

Less manual labor, fewer errors

Manually strapping items is time-consuming and prone to mistakes. Automated banding machines can be used for tasks big and small—machines can be used anywhere—offering uniform tensioning that eliminates guesswork. That reliability fosters a sense of trust and desire among companies eager to reduce overhead.

Cost-effectiveness

It may seem daunting to invest in an advanced bundler, but this approach proves cost-effective when you factor in fewer reworks, lower product damage, and less time wasted. By automating the packaging station, you optimize labor and reduce the chance of incorrectly sealed boxes.

Versatility

The range extends from movable machines for smaller setups to large-scale systems for multinational plants, bridging manual efforts and movable machines to customized machines that seamlessly integrate. For instance, a single line might handle everything from a small carton of lightweight goods to a heavier pallet containing bulky freight—no sweat.

“The modern marketplace requires agility. Automated banding solutions let you adapt in real-time, bundling anything from snack packs to larger crates.” – A Production Supervisor

Once desire has been sparked, companies often ask how to choose the right approach. After all, each product line or facility has unique packaging needs.

Analyzing the “right machine”

Identifying the right machine begins with understanding your common materials:

Examining the selection of banding

Different materials also come in a variety of widths and thicknesses. The selection of banding depends on how delicate or weighty your products are. You might want pneumatic tension control for some loads or a simpler tension dial for others. Carefully deciding helps you pick the best banding for every scenario, from delicate produce to robust construction goods.

Incorporating labeling or branding

Modern machines can incorporate labeling—e.g printing batch numbers, qr codes, or product codes directly onto the band. They might also note sell-by dates on perishable items to keep supply chains organized. This functionality transforms the bundling system into a one-stop solution, letting you track and brand each shipment conveniently.

Find the Best Banding for Different Packaging Needs

When demand escalates, high-output factories quickly realize how vital a bander can be for machine work. Whether in food, beverage, or electronics, bundling large volumes demands speed, consistency, and minimal user intervention.

Accelerating throughput

A well-chosen banding machine can wrap boxes, packages, or bundles in seconds. By programming the tension needed, each pass is uniform. That uniformity ensures your packaging lines run at peak performance, drastically reducing daily bottlenecks.

Reducing handling errors

High-volume lines risk slip-ups—like under-tightening or over-tightening. Automated machines remove the guesswork, protecting fragile goods if you must protect delicate surfaces. As soon as the operator feeds the bundle of products in, the bander delivers a consistent seal.

| KPI | Manual Strapping | Automated Banding Machine |

|---|---|---|

| Bundles/Hour | Up to 100 | 300-600+ |

| Error Rate | Up to 5% | <1% |

| Labor Requirements | 2-3 operators | 1 operator |

| Tension Consistency | Variable | Calibrated |

| Overall Efficiency | Moderate | High |

By switching to automation, managers see immediate improvements in daily throughput and monthly production yield.

For advanced wood or composite-based items, edge sealing is critical. While standard banders provide a way to bundle boxes, an edge banding machine hones in on making sure each wooden panel or board is sealed neatly and stands up to environmental stress. Trimming ensures that no leftover edges stick out or cause alignment problems.

Why does it matter?

Imagine furniture that chips at the edges or doesn’t quite line up perfectly. That’s a liability for any brand seeking to stand out for quality. The use of banding in an edge banding machine effectively addresses such finishing problems. By applying consistent tension and controlling the cutting tool, the system guarantees a smooth, sealed perimeter that also looks aesthetically pleasing.

Integrated approach

Many modern packaging or finishing lines combine standard banders with edge-banding stations. This comprehensive approach—bundling some items, finishing others—keeps the entire production line or assembly floor cohesive. Everything is seamlessly integrated into existing production flows, from machines seamlessly integrated into existing packaging lines to specialized finishing corners for woodworking machinery.

Let’s confirm why automated banding machines are a cost-effective choice, merging operational efficiency with financial wisdom.

Lower labor costs

Even a single operator can manage a fully automated system. This consolidation cuts overhead while boosting output. Over a year, the savings can be dramatic, freeing up resources to expand capacity or enhance quality in other areas.

Durability and reliability

Modern banders are built to last, featuring robust frames, advanced weld technology for seals, and a user-friendly interface. The average lifespan can stretch well beyond a decade with proper maintenance—giving you consistent returns on your initial investment.

Versatile types of strapping

By choosing the material that fits each load, you minimize waste and increase efficiency. If you handle a wide spectrum of goods, one well-equipped machine can adapt to multiple banding tasks daily, ensuring maximum utilization.

“Before installing an automated bander, we wasted hours adjusting manual tension. Now, we handle 50% more packages with half the staff.” – Factory Manager

Cost-Effective Automated Banding Machines

As a professional manufacturer of automated packaging equipment, we specialize in shaping a packaging line that aligns with your facility layout, product range, and daily throughput goals.

Why collaborate with us?

Our commitment

We don’t believe in cookie-cutter approaches. Instead, we ensure you have the right machine in the right one-stop setup. Whether you handle perishable products or heavy goods, we’ll walk you through the entire process— from selection to integration—so you can reduce costs and speed up operations.

If you’re interested in learning how to modernize your packaging or finishing, contact us at any time. We’ll connect you with one of our experts who can assess your environment and deliver a perfect match.

Sometimes, organizations wonder if banding is truly the best route for them. The good news is that banding machines can be used for countless industrial applications. They can handle diverse tasks, from printed materials to heavier items requiring steel strapping. They also help you securely bundle goods around the items—like large boxes or smaller collections of parts.

Things to remember

Did you know?

Some advanced banders come with quick-change reels so you can swap packaging material mid-run, boosting efficiency. Others have integrated conveyor sections that flow directly into your shipping zone.

How does an automated banding machine differ from using a strapping kit?

A strapping kit is a manual or semi-manual solution—often including tools like tensioners, clips, and straps. An automated banding machine removes the need for manual strapping tools, speeds up operations, and applies uniform tension more precisely.

Is there a standard tension level for all items?

No. Each product has distinct requirements. Light goods demand gentler tension, while heavier loads—like steel beams—need tighter seals. Fortunately, advanced machines let you adjust tension at will for consistent results.

Do automated banders also handle labeling or printing?

Many can. You can add data—like batch numbers, qr codes, product codes, and sell-by dates—directly onto the strap. This not only organizes your inventory but also reduces labeling errors.

Can these machines handle oversized items or odd shapes?

Yes. Machines can be used anywhere – our range extends from standard table units to large, customized machines seamlessly integrated with specialized stations. Even bulky or irregular items can be banded effectively.

Is there a recommended service interval?

Like any industrial system, routine upkeep ensures longevity. Many packaging managers schedule monthly or quarterly checks on rollers, tension calibrations, and motors, especially in high-volume environments.

Does installing a banding machine require changing my entire production floor?

Usually not. Modern banders are user-friendly and used anywhere – our range extends from smaller stand-alone machines to advanced lines that are seamlessly integrated into existing production lines.

Whether you’re a small operation or a multinational seeking top-tier banding solutions, we’re here to help you integrate the right one into your line. Our machines to customized machines seamlessly adapt to your workflow, cutting costs and boosting efficiency. If you’re ready to enhance productivity, reach out—together, we can secure your bundles and your success.