Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Is your packaging line moving too slowly? Do your workers waste valuable time forming boxes by hand? Are inconsistent cartons causing product damage during shipping?

These packaging bottlenecks cost manufacturing plants millions each year in wasted labor, material, and productivity. The typical factory worker can only form 3 boxes per minute by hand – that’s just 180 cartons per hour! Meanwhile, products pile up waiting for containers, and employees suffer from repetitive strain injuries.

This pain point is even worse when orders surge. Production stalls. Overtime costs skyrocket. Customer deliveries arrive late. Your entire operation suffers because the simple act of forming a box becomes your operation’s weakest link.

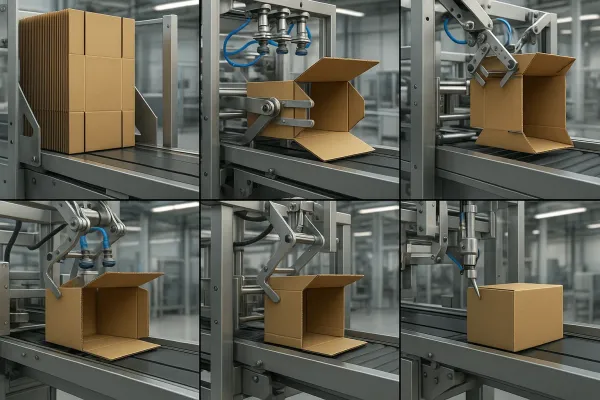

A carton erector (also called a case erector or box erector) is a specialized packaging machine that automatically transforms flat cardboard blanks into fully-formed, ready-to-fill boxes.

This powerful automation equipment uses mechanical or vacuum-powered systems to select, open, square, fold and seal the bottom flaps of corrugated cartons – all in seconds with perfect consistency.

Once installed in your production line, a carton erector becomes the foundation of efficient packaging, feeding perfectly-formed containers to downstream equipment like product loaders, case packers, and sealers.

Every automatic carton erector machine includes these critical systems:

Carton erectors come in several configurations to meet different production needs:

The high speed horizontal case erector shines in these sectors:

The transformation when moving from manual box forming to an automatic hot melt glue carton erector machine is dramatic:

| Metric | Manual Boxing | Carton Erector | Improvement |

| Speed | 3-5 boxes/minute | 15-30+ boxes/minute | Up to 900% faster |

| Output Per Shift | 180-300 boxes | 900-1,800+ boxes | 6x more production |

| Labor Required | 2+ workers per station | 1 operator per line | 50-80% labor reduction |

| Consistency | Variable | 100% uniform | Eliminates quality issues |

| Worker Safety | Repetitive motion injuries | Ergonomic operation | Reduced injury claims |

| Material Waste | 10-15% excess | 3-5% excess | 66% material savings |

| ROI Timeline | N/A | 6-18 months | Rapid payback period |

Based on industry averages for standard packaging operations

In a recent case study, a manufacturer replaced six manual box-forming positions (two per shift) with a single carton erector. At a fully-burdened labor cost of $35,000 per worker annually, the company saved over $210,000 per year. Their investment in automation paid for itself in just 2.28 months!

For optimal performance, match your semi automatic pneumatic carton former machine to your packaging needs:

To keep your carton erector running smoothly:

Q: How do carton erectors compare to case sealers?

A: Carton erectors form and bottom-seal empty boxes from flat blanks, while case sealers close and seal the top flaps of already-filled boxes. Many packaging lines use both machines in sequence.

Q: What’s the typical ROI period for a carton erector?

A: Most manufacturing facilities achieve full return on investment in 6-18 months, depending on production volume and labor costs. Some operations report ROI in as little as 2-3 months.

Q: Can one machine handle different box sizes?

A: Yes! Modern carton erectors feature tool-less changeover systems that allow quick adjustment between different box dimensions, often in under 5 minutes.

Q: What maintenance is required?

A: Routine maintenance includes cleaning vacuum cups, checking belt tensions, lubricating moving parts, and inspecting tape/glue systems. Most machines need only minimal daily attention.

Q: How much floor space is needed?

A: A typical carton erector has a footprint of approximately 8’×5’, though compact models designed for smaller spaces are available.

At Stars Creativity, we’re dedicated to helping manufacturing plants worldwide streamline packaging processes through intelligent automation. Since 2005, Qingdao Stars Creativity Technology Co., Ltd. has specialized in developing highly reliable, efficient, and customizable packaging machinery.

With over 3,000m² of production facilities and exports to 80+ countries, our comprehensive technical team supports full-line packaging automation for:

Our CE-certified, modular carton erectors deliver:

The manufacturing landscape is evolving rapidly. Labor costs continue rising while skilled workers become harder to find. Production efficiency is no longer optional—it’s essential for survival.

Don’t let manual box forming remain your operation’s weakest link. A carton erector from Stars Creativity can transform your packaging line, delivering perfectly-formed boxes at speeds that match your production needs.

Request a consultation today to discover how our systems can deliver:

Visit our website or contact our technical team to schedule an assessment of your packaging operation. We’ll help you select the ideal carton erector configuration to maximize your efficiency and profitability.

Automated Box Assembly Performance Metrics

2023 Global Market Size

Annual Growth Rate

2033 Projected Market

Labor reduction per machine

Average changeover time reduction

Material waste reduction