Para evitar atrasos na resposta ao seu pedido, indique o seu WhatsApp/Skype juntamente com a mensagem, para que possamos contactá-lo logo na primeira vez.

Responder-lhe-emos no prazo de 24 horas. Se for um caso urgente, adicione WhatsApp/WeChat: ,. Ou telefone diretamente.

Are manual strapping and slow banding tools holding your production back? Packaging delays, broken straps, and wasted time hurt your business. Discover how an electric strapping machine with LCD screen and automatic tensioner can streamline your packaging, improve safety, and maximize efficiency.

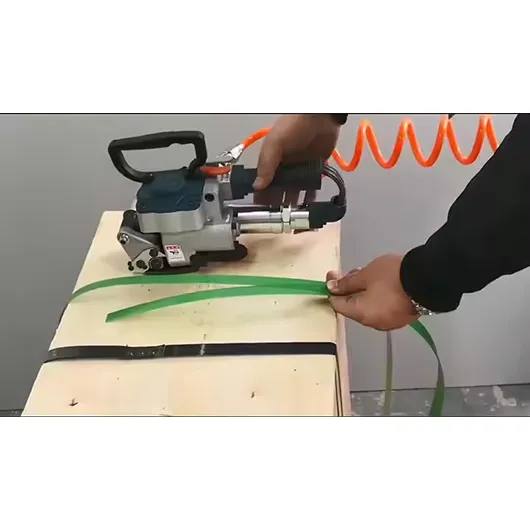

An electric strapping machine automates the strap process for cartons, pallets, and boxes, using PP, PET, or even steel straps. It applies consistent tension, seals securely, and boosts efficiency for manufacturers, warehouses, and distributors seeking reliable, fast, and cost-effective banding.

Um electric strapping machine is a battery powered, automatic banding tool designed to apply, tension, weld, and cut strap around products, cartons, or pallets. It can handle pp strap, pet strapping, and even steel strap with options for various industries such as the paper industry, steel industry, and aluminum industry.

Explore the differences with our electric strapping machine and discover the future of packaging!

Traditional manual strapping or old-fashioned banding tools slow down operations, cause inconsistent tension, and often require extra buckles or seals. Electric strapping machines solve these problems:

| Tool Type | Tension Method | Velocidade | Seal Type | Ideal For |

|---|---|---|---|---|

| Cintagem manual | Manual Tensioner Kit | Slow | Buckle/Seal | Low-volume, simple banding |

| Electric Strapping | Automatic Tensioner | Rápido | Weld/Hot melting | High-volume, heavy-duty work |

| Banding Machine | Semi/Fully Automatic | Very Fast | Weld/Seal | High-speed packaging lines |

Try the latest máquina de cintagem automática for a real performance boost.

Today’s electric strapping machines, such as the solid electric strapping machine with LCD screen, offer game-changing features for any packaging operation:

See a portable battery strapping tool in action!

Selecting the correct correia for your electric or automatic strapping machine impacts package safety and machine life.

| Strap Type | Break Strength | Aplicação | Use With |

|---|---|---|---|

| PP Strap | Médio | General, carton, box, light | Automatic/Semi |

| PET Strap | Elevado | Heavy, outdoor, pallet | Electric/Fully |

| Steel Strap | Very High | Industrial, metal | Heavy-duty/Banding |

| Woven Cord | Variável | Sensitive/fragile | Manual/Electric |

Find the best Faixa de cintagem PP for your needs.

Máquinas de cintar are available in fully automatic, semi-automatic, and manual versions. Here’s how they compare:

Discover your options with a strapping machine for packing and see how automatic strapping can transform your process.

O LCD screen in modern electric strapping machines brings transparency and control to packaging. With a clear digital display, operators can:

Machines with LCD screens reduce training time, cut human error, and increase packaging reliability—key for all B2B buyers.

Battery powered automatic banding is a game changer in the world of packaging. With 2 x 4000mAh rechargeable lithium batteries, these machines:

Battery powered automatic strapping is ideal for logistics, warehousing, or any location where mobility and speed matter.

See máquina de cintar paletes vertical totalmente automática for advanced solutions.

Pallet packaging strapping is a major use case for electric strapping machines. These machines ensure:

Strapping tensioners and packaging tensioner machines for box pallet applications guarantee load safety across the supply chain.

For robust solutions, try a strap packing machine designed for pallets.

Electric strapping machines serve a variety of sectors:

Use strapping banding machine for both general and industry-specific needs.

To keep your electric strapping machine running smoothly:

Proper care maximizes machine life and packaging reliability.

A leading warehouse switched from manual strapping tools to a battery powered, automatic strapping machine. Results:

Read about similar solutions: banding machines for sale.

How many types of straps can I use with an electric strapping machine?

Electric strapping machines work with PP, PET, and sometimes steel strap. Always check your machine’s compatibility for polypropylene, polyester, or steel banding.

What is the difference between a solid electric strapping machine and a manual strapping tool?

Solid electric strapping machines automate tensioning, welding, and sealing, while manual strapping tools require separate tensioner kits, seals, and much more effort.

Can I use my electric strapping machine for both box and pallet strapping?

Yes! Most models are designed for box, carton, and pallet packaging strapping—just select the right strap and tensioning force.

What are the main benefits of a machine with LCD screen?

LCD screens provide real-time settings, alerts, and operational status, making it easy to adjust for different loads, strap types, and banding requirements.

How does battery powered automatic banding improve efficiency?

Battery powered tools are portable, reduce downtime, and allow you to strap anywhere—ideal for large warehouses and mixed pallet loads.

Where can I find a banding kit or tensioner kit for my strapping machine?

Check out our collection for strapping machines, banding kits, and accessories.

For more product details or custom solutions, contact our expert team for a quote today!