Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Choosing the wrong conveyor can create bottlenecks, damage products, or increase maintenance costs. I’ve seen first-hand how important the right decision is.

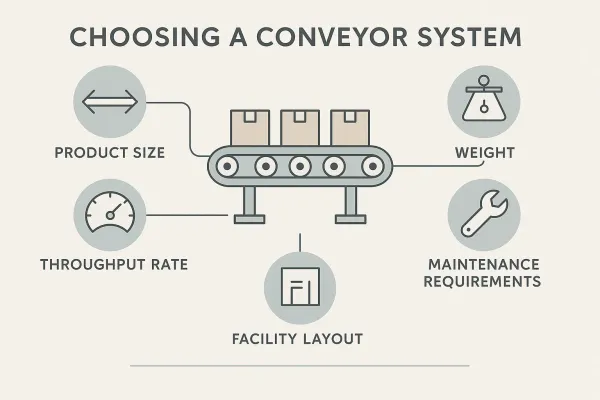

Choosing a conveyor involves evaluating your material type, application, layout constraints, required speed, and future scalability needs.

Selecting the right conveyor saves time, protects products, and supports your production growth without constant system changes. Let’s break down the key areas you need to consider.

When I first started managing equipment purchases, I thought all conveyors were basically the same. I quickly learned otherwise — a poor choice can cause endless trouble.

When selecting a conveyor, consider factors like product size1, weight, throughput rate, facility layout, and maintenance requirements.

Here’s the simple framework I use to assess conveyor needs:

| Factor | Importance |

|---|---|

| Product Type | Size, weight, fragility affect conveyor type and speed |

| Throughput Goals | Must match or exceed desired product flow |

| Facility Layout | Conveyor path must fit space and production flow |

| Maintenance | Easier maintenance reduces downtime and operating costs |

| Future Scalability | Choose systems that allow for easy upgrades |

Ignoring any of these factors can lead to expensive retrofits later. For example, I once picked a conveyor that couldn’t handle higher loads during seasonal peaks. We ended up replacing it within a year. Always plan not just for today but also for what your operations might look like in two or three years.

I used to think conveyor systems were all about speed. But after damaging several fragile products2 due to the wrong conveyor design, I realized material type matters more than anything.

The material type — its size, weight, texture, and fragility — directly influences the best conveyor choice, from belt type to drive style and construction material.

Different materials behave differently during transport. Here’s what I learned:

| Material Property | Conveyor Consideration |

|---|---|

| Heavy Loads | Need reinforced belts or roller conveyors |

| Fragile Items | Use smooth, low-impact belts or cushioned roller systems |

| Fine Particles | Require enclosed or easy-to-clean conveyors to prevent loss |

| Sticky Products | Need anti-adhesive belts or scrapers to prevent buildup |

One time we transported light plastic bottles on a heavy-duty roller conveyor designed for metal parts. The bottles kept falling between rollers, jamming the line. We had to switch to a small-pitch belt conveyor specifically designed for light, unstable products. Since then, I always match material type first before even considering speed or price.

At first, I didn’t understand why there were so many types of conveyors. But now I know — each has strengths and weaknesses depending on the application.

Different conveyor systems3, such as belt conveyors, roller conveyors, and chain conveyors, offer varying benefits based on product type, space, and handling needs.

Here’s a simplified view that helped me when making selections:

| Conveyor Type | Best For | Limitations |

|---|---|---|

| Belt Conveyor | Lightweight, fragile products | Less suitable for heavy or sharp items |

| Roller Conveyor | Heavy loads, pallets, flat-bottomed goods | Not ideal for small or irregular shapes |

| Chain Conveyor | High-strength needs, industrial parts | High maintenance, not for delicate items |

| Screw Conveyor | Powders, granules, small items | Requires sealing, limited speed |

| Modular Plastic Conveyor | Versatile, easy cleaning, curves possible | Higher upfront cost |

When I needed to move a mix of boxes and bags, we chose a modular plastic belt conveyor. It handled both types without damaging the products and made cleaning easier between production batches.

I once installed a conveyor that was too slow for our growing output. It became a bottleneck we didn’t anticipate. Lesson learned: speed and size must be calculated carefully.

To determine the right conveyor size and speed, calculate your required throughput, measure available space, and factor in your product dimensions and weight4.

Here’s the simple method I use today:

Calculate how many units you need to move per hour or per minute. Always plan for peak loads, not just average days.

Record the biggest and heaviest product you will convey. This ensures your conveyor can handle the full range.

Check the length, width, and height available for the conveyor line. Include entry and exit clearance zones.

Conveyor speed = (Desired units per minute) × (Length of product + spacing buffer). This helps avoid jamming and maintains smooth flow.

| Step | Key Questions |

|---|---|

| Throughput | How many items per hour? Peak vs. average? |

| Size | Largest product dimensions? |

| Weight | Heaviest item? |

| Layout | Any space restrictions? Ceiling height? |

| Speed | How fast must the conveyor run? |

After switching to properly sized conveyors matched to peak capacity, our overall line efficiency improved by over 25%, and we avoided costly downtime.

Choosing the right conveyor means matching product needs, facility layout, speed, and future growth goals. Careful planning today ensures long-term performance and saves future headaches.

Understanding how product size impacts conveyor choice can help you avoid costly mistakes and ensure efficiency. ↩

Explore the best conveyor systems designed specifically for fragile products to avoid damage during transport. ↩

Understanding the various conveyor systems can help you choose the right one for your needs, enhancing efficiency and productivity. ↩

Knowing how product size and weight influence conveyor design can help you select the right system for your needs. Check this resource for expert advice. ↩