Evite que su consulta sea de respuesta tardía, por favor introduzca su WhatsApp/Skype junto con el mensaje, para que podamos ponernos en contacto con usted a la primera.

Le responderemos en un plazo de 24 horas. Si para el caso urgente, por favor agregue WhatsApp/WeChat: ,. O llame directamente.

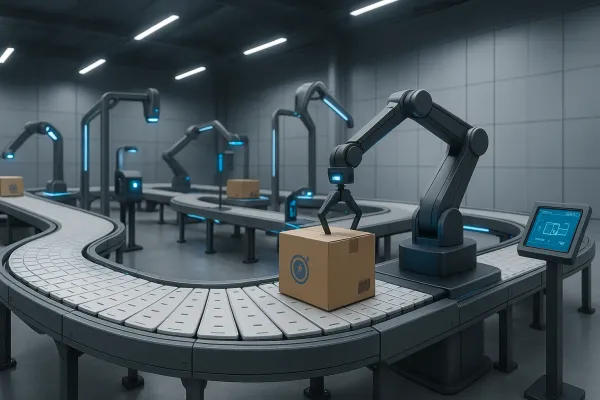

Las fábricas y los almacenes tienen un gran trabajo. Deben mover muchas cosas, muy deprisa y con mucha seguridad. Si las cosas se atascan, o los trabajadores se cansan, los pedidos salen con lentitud y se producen errores. El problema se agrava a medida que crece la demanda de envíos rápidos .

Si sólo utilizas personas, te ralentizas a medida que creces. Los trabajadores se cansan. Las cajas se amontonan. Los paquetes o materiales pueden dañarse. Pueden producirse errores a diario.

Pero, con buenos diseños de sistemas transportadores, los almacenes son más rápidos, más seguros y su funcionamiento cuesta menos. Los sistemas automatizados, como las nuevas cintas transportadoras, los transportadores de rodillos y los controles inteligentes, ayudan a las fábricas a mantener el ritmo de la demanda. De hecho, los sistemas de transporte automatizados pueden aumentar la velocidad de los pedidos en 60%-80% y reducir los errores a tan sólo 0,5%-1,5%. Es una gran diferencia.

Imagínese un ajetreo navideño. Cientos de pedidos cada hora. No hay suficiente personal. Los paquetes se pierden o se confunden. Los clientes reciben artículos equivocados. Algunas cajas se quedan paradas mientras otras pasan a toda velocidad. Toda la cola se detiene cuando una persona se cansa o se produce un atasco. Cada error supone una pérdida.

Si se siguen utilizando sistemas manuales, la situación empeora. Aumentan los costes de mano de obra, a veces 25-40% menos eficiente que las líneas automatizadas . Se alarga el plazo de entrega de los pedidos.

Necesitas diseños de sistemas de transporte para almacenes utilizando automatización inteligente. Es decir:

Expliquemos qué funciona, por qué y cómo, con datos claros y hechos científicos.

Los almacenes eligen entre una caja de herramientas de tipos de transportadores inteligentes. Elegir el adecuado depende de sus productos, su velocidad y su espacio.

Cuando diseñe un sistema transportador, tenga en cuenta estos puntos clave:

| Factor de diseño | Sistema manual | Sistema automatizado (Transportadores) |

| Producción (cajas/hora) | 300 – 500 | 2,000 – 12,000 |

| Tasa de error | 5% – 8% | 0.5% – 1.5% |

| Tiempo de actividad | 85% – 90% | 98%+ |

Tabla: Aumento de la productividad y la precisión con los sistemas transportadores

| Métrica | Manipulación manual | Sistema transportador | Mejora de la eficiencia |

| Velocidad de pedido | 60-90 min/pedido | 15-25 min/pedido | 66% - 83% Más rápido |

| Rendimiento | 300-500/hora | 2.000-12.000/hora | 400% - 2300% Más |

| Tasa de error | 5% - 8% | 0,5% - 1,5% | 80% - 90% Inferior |

| Coste laboral | Alta | 25-40% Inferior | Hasta 40% de ahorro |

Ejemplos de casos prácticos

| Empresa | Solución | Resultado |

| Centro de comercio electrónico | Clasificación | Rendimiento de 2.500 a 12.000 piezas/hora |

| Almacén de recambios de automoción | Transportador de palés | Espacio reducido por 70% |

| Proveedor 3PL (Meyer) | Transportador flexible | Reducción de la mano de obra 15%; aumento del rendimiento 15% |

Consulte la tabla siguiente para comparar las opciones para su almacén:

| Parte del sistema | Opción principal | Lo mejor para |

| Cinta transportadora | Stars Creativity, Siemens, Honeywell | Transportadores de banda modulares, rápidos y fiables |

| Clasificación | Desviadores emergentes, banda transversal, MCE | Comercio electrónico de gran volumen o clasificación de paquetes |

| Carga pesada | Cadena de arrastre, rodillos motorizados, Dematic | Palés, embalajes a granel, mercancías pesadas |

| PLC y controles | Siemens, Honeywell, Omron | Automatización de almacenes escalable, integración IIoT |

Expliquemos ahora cómo Stars Creativity apoya estas necesidades científicas y tecnológicas de las fábricas de todo el mundo.

Un buen proyecto de automatización de almacenes incluye:

Resumiendo:

Toda fábrica moderna necesita sistemas de transporte fiables y eficientes. Estos sistemas utilizan controles inteligentes, una ingeniería sólida y diseños rápidos y flexibles. Son:

Con más de 15 años de experiencia, una producción avanzada y un historial mundial, Stars Creativity suministra maquinaria de envasado y transporte que es a la vez científica y práctica, ayudándole a mantenerse al día con la demanda mundial, de forma segura y rentable.

Este artículo es un recurso técnico para directores de planta, ingenieros y planificadores logísticos, basado en datos científicos contrastados, mejores prácticas probadas e historias de casos operativos de líderes mundiales en el diseño de sistemas transportadores automatizados.