Si votre demande n'est pas traitée dans les plus brefs délais, veuillez indiquer votre adresse WhatsApp/Skype dans le message, afin que nous puissions vous contacter dès la première fois.

Nous vous répondrons dans les 24 heures. En cas d'urgence, veuillez ajouter WhatsApp/WeChat : ,. Ou appelez-nous directement.

Is your labeling process holding your business back? Many companies waste time and money on slow, inconsistent, or manual labeling—hurting product quality and slowing growth. A better approach? Use the right labeling machines to streamline your labeling process, boost efficiency, and improve your brand image.

To produce and apply labels efficiently, you’ll need several types of labeling machines and label printers. These solutions make it easy to print, position, and apply labels on all types of products, packaging, or containers, allowing your operation to scale and compete in today’s fast-moving world.

Labels are everywhere—on every box, bottle, package, and product you see. But for B2B buyers in manufacturing, logistics, warehousing, and e-commerce, labels are more than just stickers—they’re an essential part of business operations. If you’ve ever lost track of inventory, made a shipping mistake, or faced a compliance headache, you know how critical the right label can be.

Key reasons labels matter:

“Without an efficient labeling system, companies risk errors that can lead to costly recalls or lost business.”

- Global Packaging Industry Report, 2024

Labels are not just about sticking paper onto a box. They are the backbone of modern inventory management and product distribution. This is why selecting the right labeling equipment is vital for any company looking to compete.

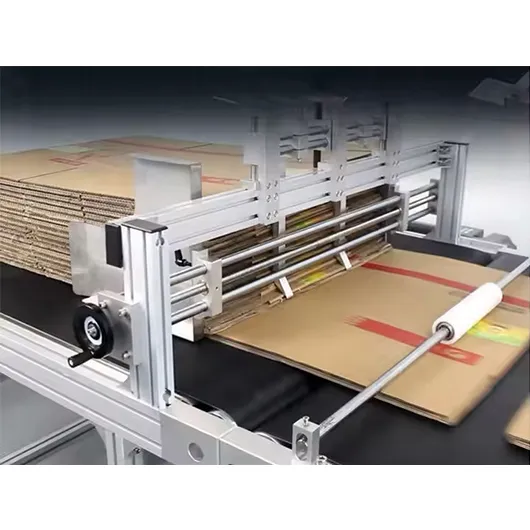

A labeling machine automates the process of applying labels to containers, products, or packaging—saving time, reducing errors, and improving consistency. But how does a labeling machine work in real-world operations?

Labeling machines are designed to accommodate several size configurations, label shapes, and materials. For example, a Étiqueteuse supérieure entièrement automatique autocollant can apply up to 1000 labels an hour on a production line, while a semi-automatic double-sided labeling machine can label square products and boxes with ease.

Types of labeling equipment ranging from low to high volume labeling are available, letting you scale your operations as needed.

Choosing the right type of labeling equipment depends on your product, production volume, and business goals. Here’s a quick table summarizing common labeling equipment types and their best uses:

| Type of Labeling Machine | Idéal pour | Label Shapes & Sizes | Typical Capacity | Notes |

|---|---|---|---|---|

| Handheld Label Applicator | Small batches, on-the-go | Portable label, label tape | 100-1000 labels/hr | Great for facilities teams, remote jobsites, or variable product sizes |

| Semi-Automatic Labeling Machine | Flexible production lines | Varying label shapes/widths | 500-3000 labels/hr | Balances speed with flexibility, ideal for mid-size companies |

| Fully Automatic Labeling Machine | High-volume, continuous | All label shapes and sizes | 3000-10,000+ labels/hr | Can run in-line with other equipment, minimal labor, best for scaling up |

| Bottle Labeling Machine | Bottles, round containers | Wrap-around, front & back | 1000-6000+ labels/hr | Specialized for beverage, pharma, and food industries. See more |

| Rotary Labeling Machines | Maximum throughput | Large amounts, many sizes | 10,000+ labels/hr | Used by large-scale bottle manufacturers. Expensive, but the gold standard for speed |

| Automatic Sticker Applicator | Cartons, flat surfaces | Adhesive label, label sheets | 1000-5000+ labels/hr | Popular for e-commerce, shipping, and retail. Learn more |

Fait : According to industry statistics, “companies that automate labeling processes see a 30% reduction in labor costs and a 25% improvement in labeling accuracy.”

When it comes to actually making the labels, you have two main options: label printers et label makers.

Label printers are ideal for businesses that need to print labels in bulk—shipping, inventory, packaging, or compliance labels. Common types include:

Label makers, on the other hand, are best for “on-the-fly” labeling—like shelf tags, cable wraps, or asset management. Most are portable or desktop models that use label tape cartridges and are operated by pressing a few buttons.

“A good label maker provides the flexibility to make labels anywhere, anytime. For larger operations, a dedicated label printer integrated with the production line is a must.”

Key point: It’s helpful to learn that choosing between a label printer and a label maker depends on whether you need to create labels in large quantities or on demand.

Handheld label makers et portable label applicators offer unmatched flexibility for jobs that require mobility or quick response. These devices are perfect for fieldwork, equipment labeling, shelving, and maintenance tasks—especially when you’re labeling products in multiple locations.

Typical uses for handheld labeling solutions:

Advantages of handheld labeling equipment:

If you’re operating a small business, moving between sites, or need to label small batches, a handheld label maker is an easy and affordable way to get started.

Conseil de pro : For growing companies, handheld solutions are a bridge before investing in more complex automatic or semi-automatic labeling machines.

When your labeling needs outgrow manual application, it’s time to evaluate semi-automatique et fully automatic labeling machines. The main difference comes down to volume, labor, and required precision.

Fait : Research shows that moving from hand applying labels to semi-automatic machines can boost output by 4x, and to fully automatic labeling machines by 10x or more.

Étude de cas :

A medium-sized beverage company transitioned from manual bottle labeling to an Machine automatique à étiqueter les bouteilles rondes. The result? They cut label waste by 15%, reduced labor costs, and ramped up output to 5,000 bottles per shift—all while ensuring every bottle had the right label, perfectly positioned.

Label applicators are machines designed to apply labels precisely onto containers, boxes, or flat surfaces. The right applicator ensures your labels stick evenly, without bubbles or wrinkles—even at high speed.

Common types of label applicators:

Conseil : Sometimes it’s cost effective to outsource or hand apply labels for very small runs, but as your volume increases, investing in a dedicated label applicator quickly pays off.

Buying labeling equipment is a strategic investment. Here are five tips for buying labeling equipment and maximizing your ROI:

Le saviez-vous ?

Choosing a machine that supports low to high volume labeling can save you from having to upgrade again as your business grows.

The global labeling equipment market is booming, driven by e-commerce, automation, and stricter supply chain requirements. According to recent reports:

Chart: Adoption of Automatic Labeling Machines (2018–2024)

| Year | % of Companies Using Auto Labelers |

|---|---|

| 2018 | 38% |

| 2020 | 47% |

| 2022 | 56% |

| 2024 | 63% (projected) |

“Automatic labeling is becoming standard, not just for large enterprises, but for fast-growing SMEs as well.”

- Packaging World Magazine, 2024

What types of label makers are best for small businesses?

For small batches or on-demand labeling, handheld label makers or portable label printers are ideal. They’re affordable, require little setup, and let you create labels quickly wherever you need them. For growing volumes, consider a semi-automatic labeling machine for more efficiency.

How do I know which kind of printer is right for my labels?

It depends on your label size, material, and daily volume. Thermal printers are best for shipping and barcodes, inkjet or laser printers suit colorful branding. If you need to print labels in bulk, choose an industrial label printer for reliability and speed.

Can automatic labeling machines handle varying label shapes and sizes?

Oui, la plupart fully automatic labeling machines accommodate a range of label shapes and sizes and can be adjusted to different containers. Look for models with flexible configuration to handle all your packaging needs.

Is hand applying labels still common in today’s production lines?

Hand applying labels is still used for very small batches or custom items. But for most commercial operations, switching to semi-automatic or automatic labeling equipment saves time, reduces errors, and ensures label consistency—especially when labeling bottles or square products.

What are the maintenance needs for labeling equipment?

Routine cleaning, sensor checks, and occasional replacement of rollers or adhesive parts keep your machines running smoothly. Reputable manufacturers provide easy-to-follow maintenance schedules and local support. See automatic sticker applicators with simple maintenance features.

How can I ensure the right label positioning every time?

Choose labeling machines with built-in alignment sensors and adjustable guides. For complex products, in-line automatic machines provide precise label positioning even at high speed, reducing waste and rework.

Applying labels is an easy and affordable way to boost your product’s value and operational efficiency—when you have the right equipment. Whether you need a handheld label applicator, a semi-automatic labeling machine, or an automatic label printer for high-speed lines, today’s solutions are designed to scale with your needs. With thoughtful planning and the right manufacturing partner, you can move beyond hand application, streamline your labeling process, and set your business up for lasting success.

Want expert advice on choosing the best label machines for your workflow?

Visitez notre complete labeling equipment portfolio or contact our team for a free consultation.