Evita che la tua richiesta sia una risposta tardiva, inserisci il tuo WhatsApp/Skype insieme al messaggio, in modo da poterti contattare al primo colpo.

Vi risponderemo entro 24 ore. Se per il caso urgente, si prega di aggiungere WhatsApp/WeChat: ,. O chiamare direttamente.

Siete stanchi degli sprechi di film e dei costi di manodopera dovuti all'avvolgimento manuale? L'avvolgimento inefficiente dei pallet mette a rischio le spedizioni e i profitti. È ora di ottimizzare la linea di imballaggio con una macchina avvolgitrice automatica.

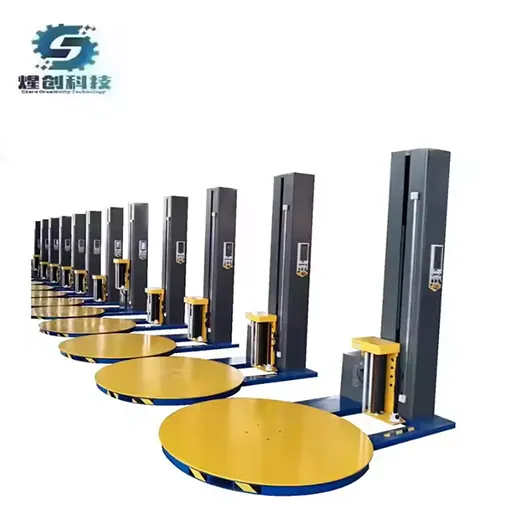

Una macchina avvolgitrice è un'apparecchiatura specializzata che utilizza il film estensibile per avvolgere strettamente i pallet, garantendo un imballaggio sicuro ed efficiente per il trasporto o lo stoccaggio. Queste macchine, automatiche o semiautomatiche, aumentano la produttività, riducono i costi e migliorano la sicurezza del carico per le operazioni B2B.

A macchina avvolgitrice è una soluzione automatizzata progettata per avvolgere in modo sicuro il film estensibile attorno ai carichi dei pallet, assicurando che le merci rimangano intatte durante la spedizione e lo stoccaggio. La macchina applica una tensione e una sovrapposizione costanti, garantendo un imballaggio più resistente e uniforme rispetto ai metodi di avvolgimento manuali.

Come funziona?

Esplora il nostro macchina avvolgitrice automatica per pallet per l'avvolgimento di pallet su scala industriale senza soluzione di continuità.

Per le attività di produzione, logistica e magazzino, il tempo è denaro e anche la sicurezza dei prodotti. Affidarsi all'avvolgimento manuale espone l'azienda a diversi rischi:

Macchine avvolgitrici automatiche e semiautomatiche risolvere questi problemi:

È possibile trovare un sistema avanzato di macchina avvolgitrice per pallet opzioni adatte a operazioni sia automatiche che semiautomatiche.

Esistono diversi tipi di macchine avvolgitrici per le diverse esigenze di carico dei pallet e di produttività:

| Tipo | Come funziona | Ideale per |

|---|---|---|

| Avvolgitore a tavola rotante | Il pallet si trova su una piattaforma girevole motorizzata che ruota mentre il carrello della pellicola si muove verticalmente. | Carichi standard o stabili, volume medio/alto |

| Avvolgitrice a braccio rotante | Il braccio ruota intorno al pallet fermo, applicando la pellicola | Carichi pesanti, instabili o fragili |

| Avvolgitore orbitale (ad anello) | Il film estensibile si avvolge orizzontalmente intorno a prodotti lunghi (utilizzando un anello rotante) | Tubi, porte, legno, carichi a forma di pannello |

Le due categorie principali.automatico e macchine avvolgitrici semiautomatiche-Adeguarsi alle diverse esigenze operative.

| Caratteristica | Semi-automatico | Automatico |

|---|---|---|

| Manodopera richiesta | Operatore per carico/scarico | Minimo |

| Produttività | Fino a 25-35 carichi/ora | 50-80+ carichi/ora |

| Integrazione | Trasportatore autonomo o di base | Integrazione completa, in linea |

| Prezzo | Più basso | Un ROI più alto, ma migliore |

| Capacità di pre-stiramento | Sì, di solito regolabile | Sì, spesso programmabile |

| Impacco personalizzabile | Regolazione manuale | Automatico, memoria dei modelli |

Per l'alta velocità, si consiglia di attrezzature per l'avvolgimento con film estensibile che si integra direttamente con la linea di trasporto.

Selezione del migliore avvolgitore per pallet o macchina avvolgitrice significa soppesare diversi fattori tecnici e operativi. Ecco quali sono le priorità dei buyer e dei responsabili del packaging B2B:

Volete avvolgere oggetti che non siano pallet? Provate il nostro macchina avvolgitrice di scatole per i cartoni e le scatole di dimensioni strane.

Film estensibile (noto anche come film estensibile) è un film plastico ad alte prestazioni progettato per garantire la massima sicurezza del carico e minimizzare gli sprechi. La scelta del film e la capacità di prestiro della macchina possono influenzare drasticamente i costi di imballaggio e la stabilità dei pallet.

"Con il prestiro, il consumo di film è diminuito di 40% e i danni al carico sono quasi scomparsi".

- Supervisore dell'imballaggio, fornitore industriale

Per operazioni con requisiti unici o ad alto volume, attrezzature per l'avvolgimento con film estensibile possono essere personalizzati per soddisfare le vostre esigenze di materiale e di produzione.

Apparecchiature di avvolgimento automatico è fondamentale per qualsiasi operazione di confezionamento B2B ottimizzata. Le possibilità di integrazione includono:

L'automazione dell'avvolgimento dei pallet offre un ROI sostanziale grazie al risparmio di manodopera, materiali e danni. Ecco cosa ottengono di solito i nostri clienti:

| Metrico | Avvolgimento manuale | Semi-automatico | Automatico |

|---|---|---|---|

| Film utilizzato (kg/pallet) | 1.3 | 1.0 | 0.8 |

| Pallet avvolti/ora | 8-10 | 20-30 | 45-80 |

| Tasso di fallimento del carico | 7-10% | 2-4% | <1% |

| Manodopera richiesta | Alto | Medio | Minimo |

Esempio di ROI:

Un fornitore di servizi logistici ha aggiornato macchina avvolgitrice automatica per palletrisparmiando ogni anno $30.000 in film e costi di manodopera, con un periodo di ammortamento inferiore a 18 mesi.

"Abbiamo dimezzato l'uso di pellicole e aumentato la produttività di tre volte. Il nostro investimento si è ripagato nel primo anno".

Moderno macchine avvolgitrici sono progettati per una facile integrazione:

Per esigenze particolari, come la protezione dei bagagli o delle borse aeroportuali, esplorate macchina avvolgitrice per bagagli aeroportuali e confezionamento di borse in aeroporto soluzioni.

Produzione e distribuzione:

Un robot da cucina installato macchina avvolgitrice per pallet nel loro magazzino, riducendo la manodopera dei turni di 35% ed eliminando virtualmente il collasso dei pallet durante il trasporto.

E-Commerce Fulfillment:

Un retailer con un'elevata varietà di unità di vendita al dettaglio ha aggiunto una macchina avvolgitrice di scatole per automatizzare l'impacchettamento di piccoli pacchi, risparmiando spazio e aumentando la produttività di 27%.

Industria pesante:

Un impianto di produzione di bobine e pneumatici sfrutta macchina avvolgitrice di rotoli estensibili per un imballaggio durevole e a prova di polvere dei loro prodotti di grandi dimensioni.

Come scegliere tra una macchina avvolgitrice a tavola rotante e una a braccio rotante?

I modelli a tavola rotante sono ideali per pallet stabili e standard. Le macchine a braccio rotante sono indicate per carichi pesanti, alti o instabili che non devono ruotare.

Posso utilizzare la stessa macchina avvolgitrice per pallet di diverse dimensioni?

Sì, la maggior parte avvolgitori per pallet e macchine avvolgitrici sono regolabili per un'ampia gamma di altezze e dimensioni dei pallet.

E per quanto riguarda le forme strane, come tubi o pneumatici?

Per le forme non standard, considerare un macchina avvolgitrice orizzontale o macchina avvolgitrice di rotoli estensibili.

Posso automatizzare sia la pallettizzazione che l'avvolgimento?

Sì, soluzioni come attrezzature per l'avvolgimento con film estensibile e distributore automatico di pallet possono essere integrati per ottenere un'automazione completa.

Che cos'è l'avvolgimento manuale e quando si usa?

L'avvolgimento manuale viene applicato a mano. È adatto per imballaggi a basso volume o di emergenza, ma non è efficiente o coerente per le operazioni B2B regolari.

Siete pronti a ottimizzare le operazioni di imballaggio e a proteggere ogni spedizione?

Contattateci per avere una consulenza esperta, una gamma completa di macchine avvolgitricie un supporto dedicato per i vostri obiettivi di automazione del packaging B2B.