Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Are you looking for ways to make your food packaging faster and better? High-speed banding machines can help! These smart machines put bands around your food packages quickly and neatly. They work well in busy food plants where you need to pack lots of things fast.

A banding machine puts strong straps around boxes, bundles, or stacks of food products. These bands hold everything together tight. The high-speed ones can do this very fast!

Key facts about these machines:

Food factories need to pack things very fast. They also need to make sure food stays clean and fresh. Banding machines help with both!

Meat, bakery, and frozen food companies see big improvements when they use these machines. For example, poultry processors work 40% faster with good banding machines. One big food company stopped losing $220,000 every year in damaged products after they started using high-speed banding!

The banding process is simple but smart:

Food plants need special features in their banding machines. The best ones have:

| Feature | Why It Matters |

|---|---|

| Stainless steel parts | Easy to clean, won’t rust |

| Washdown design | Can be cleaned with water |

| Food-safe bands | Meet FDA rules for food contact |

| Fast band changes | Less time waiting |

| Easy controls | Workers can use it without problems |

“Our banding machine helped us pack 35 bundles of cans every minute. We also had 75% fewer broken bands than before,” said a big beverage company .

Not all banding machines work well for food. You need to pick one made for food plants. Here’s what to look for:

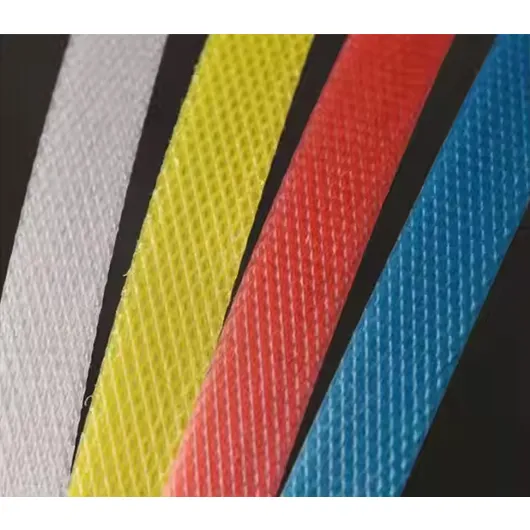

Food companies often use bands that are 9mm-12mm wide. These work well for most food boxes. Some bakeries use 5mm plant-based bands that are good for the earth .

There are several types of banding machines for different needs:

These can be moved around your plant. They work well if you need to band different products in different areas .

These connect to your production line. The packages move through without stopping. These are best for very busy food plants .

These can band many packages at once! They are super fast for high-volume food packaging .

Food companies see big improvements when they use high-speed banding machines:

Most companies get their money back in 8-18 months because they save so much on labor and waste!

Food safety is very important. Banding machines in food plants must be easy to clean.

The best machines meet strict food safety rules like NSF/ANSI Standard 3. This means they’re safe to use around food.

Different foods need different bands:

| Band Type | Good For | Features |

|---|---|---|

| PP (Polypropylene) | Most food boxes | Strong, cheap, flexible |

| PET | Heavy frozen foods | Very strong, won’t stretch |

| PLA | Eco-friendly bakery | Plant-based, breaks down in nature |

The right band keeps your packages safe without breaking or coming loose during shipping.

When you get a new banding machine, here’s how to make it work best:

It’s smart to test your actual food products on the machine before buying it. Different foods (like greasy meat boxes or flour-covered bakery items) may need different settings.

Buying a high-speed banding machine costs money now but saves money later.

Most food companies get their money back in under 18 months! After that, the savings keep coming.

To keep your machine running smoothly:

A well-maintained machine can work for many years without big problems.

The best banding machine comes from a good supplier who understands food packaging. Look for:

A good supplier will help you find exactly the right machine for your food products.

Stars Creativity makes reliable automatic banding machines that work well in food plants. Their machines have:

Their box bander machines work great for many foods, from frozen dinners to bakery items. They also offer automatic strapping machines for bigger or heavier food packages.

Ready to make your food packaging faster and better? Here’s how:

Soon you’ll have neater packages, happier workers, and lower costs!

High-speed banding machines help food companies pack products faster and better. They:

The right machine depends on your food products, speed needs, and plant setup. With the right banding machine, your food packaging will be faster, neater, and more cost-effective.

Note: The data in this article comes from food industry standards and packaging case studies. Actual results may vary based on your specific products and production environment.

| Special Feature | Why It Matters |

|---|---|

| Stainless steel | Easy to clean, won’t rust |

| Washdown design | Safe for water cleaning |

| Food-safe bands | Keeps food packages safe |

| Easy controls | Workers can use quickly |