Avoid your inquiry is delay response, please enter your WhatsApp/Skype along with the message, so we can contact you at the very first time.

We will reply you within 24 hours. If for urgent case, please add WhatsApp/WeChat: ,. Or call directly.

Labels slipping, skewing, and slowing your line? That pain grows with every order. Misplaced labels stall packaging, trigger rework, and drain profit. The solution is an automatic labeling machine that places each label precisely, at speed, with less manual labor and fewer errors.

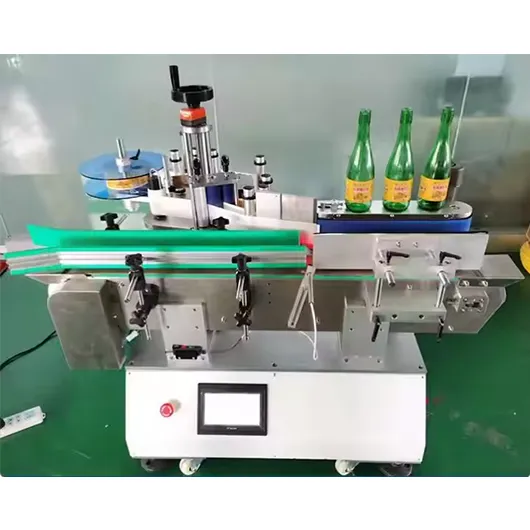

An automatic labeling machine is an integrated labeling system that feeds products, dispenses a label from a label head, and apply labels onto bottles, cans, jars, cartons, or pouches at controlled speed. Modern automatic label applicators work in-line with a conveyor, print data when required, verify placement, and support wrap-around label, two-sided, top and bottom, and other labeling applications at high speeds, enhancing productivity and consistency.

What Is an Automatic Labeling Machine?

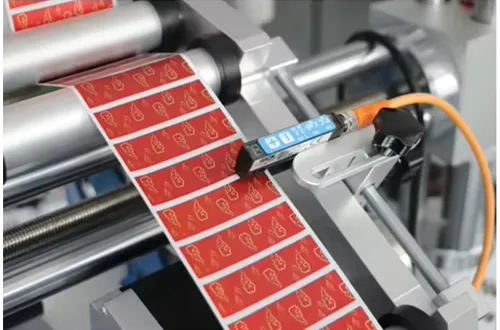

An automatic label applicator meters products on a conveyor, measures position with sensors, peels a pressure-sensitive label from a web, and places it on the container with a tamp pad, wipe, or roll-on module. Servo motion controls the label feed so the driven label meets the surface exactly where you want it—front, back, two-sided, or wrap-around.

Most labeling machines use closed-loop control to hold speed and placement, even as production rates fluctuate. Add-ons include rewinder handling, coding (date/lot), vision check, and eject of any cylindrical products or rectangular packs that miss the target. Machines are designed for cleanability and quick changeovers so operators switch label size or container style quickly and efficiently.

“Machines apply labels the same way every time—your brand, your compliance text, your barcode—without drift.”

Choose by container geometry and label location:

If you focus on round bottles, study bottle labelers that support wrap-around label and “labels to the front” alignment. For square or flat packs, an in-line wipe-on applicator offers versatility across packaging SKUs. When you need traceability for shipping, consider print and apply labeling to place serialized SSCC labels.

Throughput depends on container size, label size, and method (wipe, tamp pad, or rotary). Typical production lines see ranges from 25 to 300 products per minute, with premium rotary labeling platforms for beverages exceeding 500 in specialized cases. Realistic ranges help planning, line balancing, and ROI.

For planning, evaluate labels per minute and upstream/downstream buffers. Specify a servo driven label feed to stabilize placement as speeds rise. If you’re scaling, choose a platform designed to accommodate a wider label roll, longer web path, and faster encoder so upgrades don’t force a full replacement.

A

should integrate with fillers, cappers, cartoners, and case packers. Align in/out heights and controls, then tie into line PLCs for stop/start and jam logic. Where compliance matters (barcodes, nutrition panels), align with GS1 and regulatory references so your labels carry the right data and format.

Our system is designed to slot into upstream machinery and downstream inspection with minimal disruption. Match automation signals, network the HMI, and document parameters so operators repeat changeovers consistently. That kind of discipline improves reliability and durability over years of daily use.

Integrate a labeling system into existing production lines

Label locations drive hardware:

The module choice (wipe-on, tamp pad, air-assist) and label type (pressure-sensitive) depend on material, shape, and finish. For cylindrical containers, rollers keep the label smooth with no tunneling. For rectangular packs, belt aligners hold squareness during application.

Print and apply labeling prints barcodes, dates, or variable text and places the label instantly. It’s ideal for shipping carton faces, logistics units, and pallets—where unique IDs (SSCC) matter. Label printers paired with applicators ensure scan-grade codes and correct AI data.

Preprinted labels shine for colorful branding and glossy finishes on primary packs. Hybrid lines do both: a branding label plus a small variable-data label. Follow GS1 barcode guidance to keep codes readable at checkout and in the warehouse.

Semi-automatic units suit small production runs or pilot SKUs. Operators place each container and trigger the cycle. They are compact, often tabletop or portable, and low-cost to start.

Jump to automatic or automatic label applicators when orders grow. You’ll gain cost savings through fewer touches, improved productivity, and steadier production rates—all while maintaining consistent label placement on each container.

Automatic Round Bottle Labeling Machine

Tabletop systems are quick to deploy, compact, and great for seasonal peaks or R&D. They accept cylindrical and rectangular items with simple jigs.

In-line machines are the long-term backbone of a plant. They meter flow, buffer upstream surges, and ramp to high-speed duty. Add a rewinder, missing-label detect, and eject to protect quality. Choose stainless frames for washdown and durable bearings for long life.

When high speeds matter, rotary platforms grip the bottle on a turret and hand it past multiple stations. This architecture achieves 300–600+ bpm in certain beverage applications. Use this when the line goal is throughput with precise label registration and minimal scuff marks.

If you don’t need that extreme output, an in-line labeler with a synchronized conveyor often delivers a better total cost for mid-volume SKUs.

Add coding for date/lot; vision to confirm label presence, position, and barcode grade; and tamper-evident tabs for regulated segments. Food producers should track current FDA guidance (nutrition panels and possible front-of-pack signals). Aligning early avoids artwork rework later—and optimizes retail scan rates.

In warehouses, GS1-128 and AIs carry batch/lot and dates, enabling recalls and trace. Your labels then work for both customer and regulator.

Tally the touches removed, rework avoided, and throughput unlocked. Consider: fewer workers staging labels, steadier automation, and fewer chargebacks from mislabeled carton shipments. Typical mid-range lines move 80–200 per minute; that consistency sets realistic staffing and inventory plans.

A credible industry pulse from PMMI shows why many buyers prioritize labeling upgrades during labor shortages and SKU growth—faster changeovers, reliability, and flexibility drive the business case.

Great labeling machines balance durability with clean design. Look for protected controls, enclosed cabling, rated drives, and stainless where needed. Spare kits and PM checklists make uptime predictable.

Machines are built with guarded nip points, lockable casters, and clear HMIs. That makes training easy and setups repeatable, even with new teams. In short, machines are built for daily use—and machines are designed to be safe.

A regional beverage brand moved from hand-placed labels to an automated labeling cell. Switches included:

Outcome: steadier labels at 160 bpm, lower rework, and shorter lead times. The same cell also handles short runs with a semi-automatic station—true versatility for promotions.

A clear touchscreen guides loading, threading, and recipe selection. Color prompts reduce errors and shorten changeovers. Fast in/out label threading and modular peeler plates save minutes every shift.

Plan SOPs for web dispense, backup rolls, and safe cleaning around sensors. Train operators on skew fixes and adhesive troubleshooting so they keep the label crisp. Add QR tutorials on the HMI for visual steps.

Look for a seasoned OEM who offers consultation, proves their labeling solution with samples, and supports FAT/SAT. Request drawings that show how the system is designed for your footprint, change parts, and future add-ons (modules like printers, vision, or top apply).

Ask for references in large production environments, warranty terms, and rapid parts support. Your goal is a partner who helps you automate without disrupting flow—and who stays through startup and training.

| Labeling type | Typical containers | Placement style | Typical throughput (labels per minute) | Best use | Example model |

| Tabletop wrap-around | Small cylindrical bottle, jar | Wrap-around | 20–60 | Pilots, small production runs | Tabletop and flat plane top-side labeling machine |

| In-line side/top | Flat bottles, carton faces | Side labeling / top and bottom | 80–200 | Food, HBA, household | Automatic flat corrugated carton top-side labeler |

| Rotary carousel | Beverage round containers | Wrap-around label | 300–600+ | High-speed beverage | Automatic round bottle labeling machine |

| Print & apply | Cases, pallets | Side/top apply | 10–60 | Logistics, SSCC, variable data | (Pair label printers with applicator) |

Example models link to detailed pages for further study.

Impact on operations (higher is better)

Throughput | ██████████████

Accuracy | ████████████████

Labor saved | ████████████

Changeovers | ████████

Compliance | █████████████

What is the difference between an applicator and a full labeling machine?

An applicator is the head that dispenses and places the label; a full labeling machine includes product handling (conveyor, guides), controls, and safety. For shipping cartons, an applicator with label printers integrates as automated labeling systems.

How do I size a system for bottles and cans without overbuying?

Estimate the tightest SKU’s dwell time, then select a labeler rated slightly above your need. A flexible labeling system with quick change parts lets you run both bottles and cans on one frame as you automate volume.

Where should I place nutrition or barcode labels on food packaging?

Follow FDA guidance for statement order and placement, and GS1 standards for barcode size, location, and human-readable text. This protects scan rates and compliance as volumes rise.

Do I need print and apply labeling for e-commerce?

If your operation ships cases or pallets with unique IDs, yes—print and apply labeling keeps data fresh and readable, tying shipments to WMS records on the fly. It reduces keystrokes and mis-shipments.

What about tamper-evident or safety features?

Look for tamper-evident tabs, interlocked guards, and clear e-stops. Verify codes with vision. Choose frames and parts that are easy to sanitize to sustain uptime and brand protection.

How do labeling machines help with staffing challenges?

Automated labeling machines help stabilize output and reduce repetitive tasks. Teams focus on QA and materials instead of hand placing labels—a direct route to cost savings and steadier schedules.

Label, labeling machine, label applicator, applicator, labeling system, automatic, automated labeling, automate, labeler, conveyor, wrap-around, top and bottom, rotary, in-line, tabletop, pressure-sensitive, cylindrical containers, bottle, can, jar, pouch, label printers, rewinder, tamp pad, adhesive, module, production lines, machinery, durable, reliability.

Sources